Overview

| 1-7

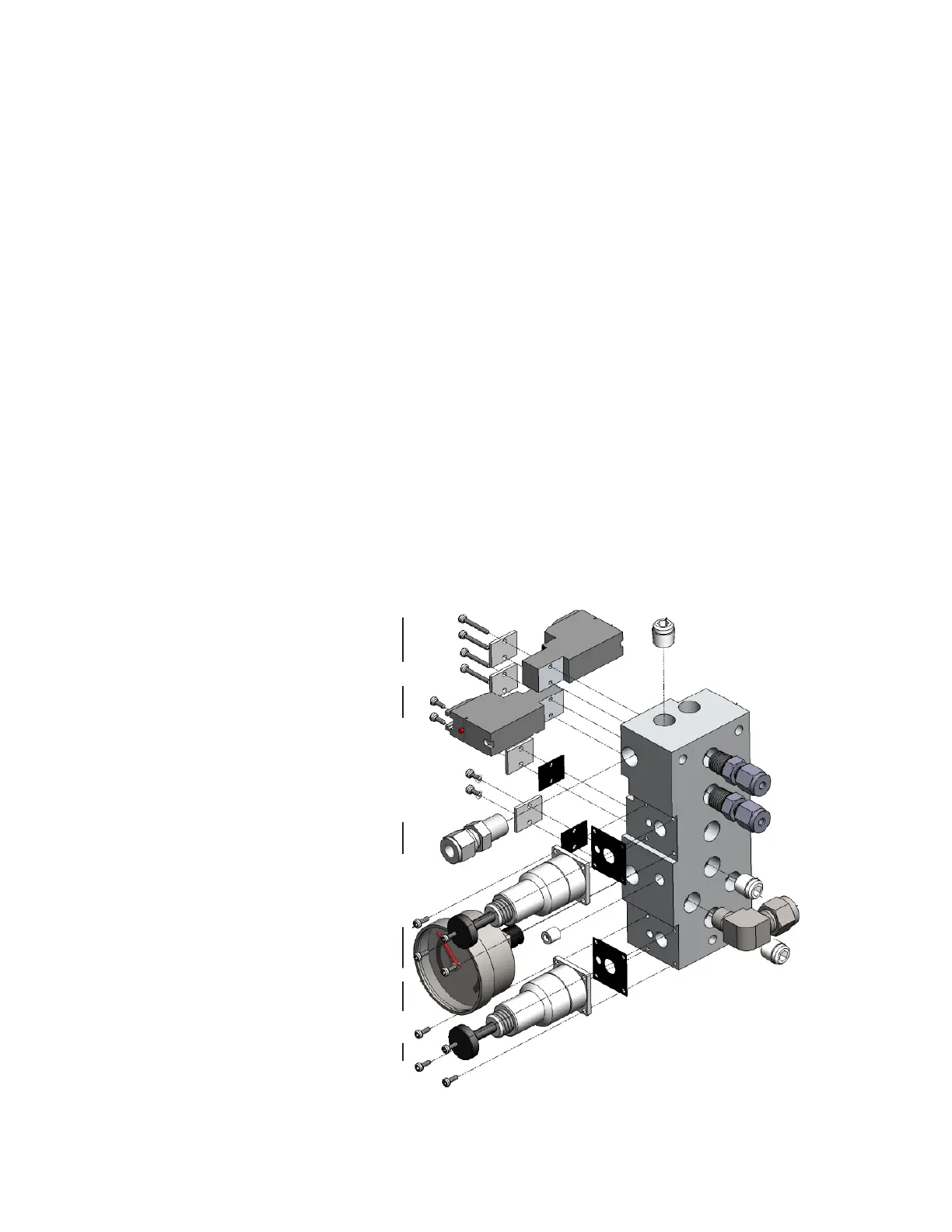

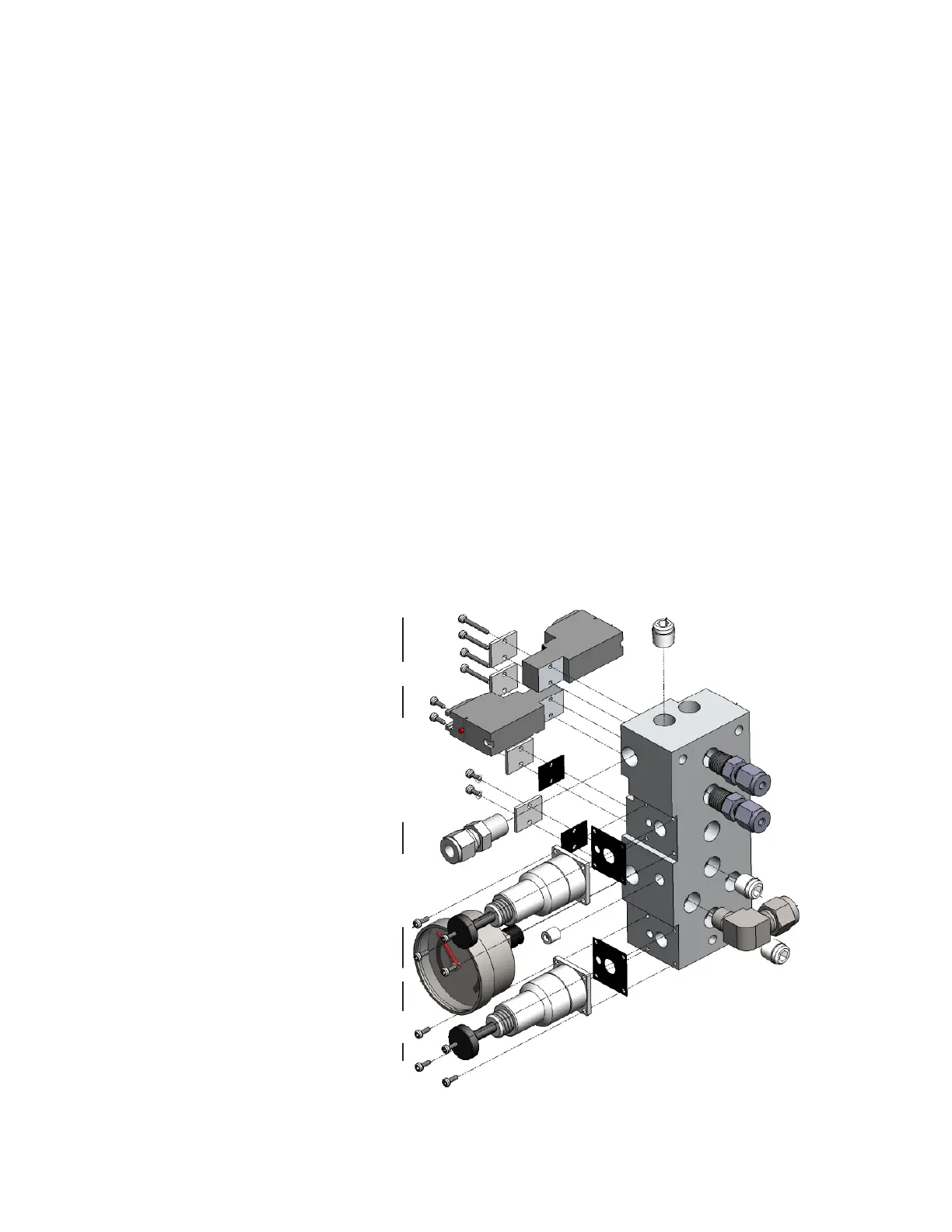

Demister

The demister is used to condense sulfur vapor in the sample stream by lowering

the sample gas temperature to 129 °C. The demister cooling is done by injecting

air around the central demister tube that has been fitted with heat transfer fins.

Two coalescing pads (one Teflon® pad and one stainless steel pad) are located

inside the demister. The demister pads provide increased surface area to help

condense the sulfur vapor present in the stream. The air or nitrogen that is used

to cool the demister originates from SV1 (solenoid valve 1) on the solenoid valve

manifold in the electronics enclosure. The air or nitrogen enters the oven through

the tube bushing assembly. The demister temperature is measured by RTD 2.

Sample Cell

The sample cell module consists of either a 2.5” (6.35 cm) or 5” (12.7 cm) 316 stain-

less steel cell body, two UV-grade, fused silica windows, two Teflon® gaskets,

and two retaining rings. The fused silica windows are O-ring sealed at both ends.

The retaining rings and Teflon® gaskets hold the window against the O-rings.

The cell body has two ¼” Swagelok tube fittings to couple with the rest of the

sample system. The sample cell is secured to the light tube via 1 SST plate as well

as a thumb screw located below the center of the cell body.

Aspirator

The aspirator pressure regulator and pro-

portional solenoid valve (PSV) control the

flow of instrument air or nitrogen through

the aspirator. The air flow to the aspirator

enters through the tube bushing assembly

into the oven where the aspirator drive air

is pre-heated by an aluminum heat ex-

changer. There is also a check valve in series

with the aspirator drive air. The gas flow

produces a slight negative pressure in the

cell to move process gas through the sample

cell. The desired sample flow rate is 1.5 ±

0.5 liters-per-minute.

The manifold assembly is located in the

electronics enclosure. A part of that assem-

bly is a small gauge (Item 60, Figure 1-6).

Adjust the aspirator pressure regulator to

produce an output of approximately 10 PSI

above process pressure. The analyzer will

control the duty cycle to a PSV to keep the

sample flow rate at the desired level. Alter-

nately, the analyzer can be configured to

manually set the PSV duty cycle.

Loading...

Loading...