24 I

I – 3 Turning Specific Operations

Presets

The functionality has been explained previously in this manual (See

"Presets" on page 10). The explanation and examples on those pages

are based on a mill application. The basics of those explanations are

the same for turning applications with two exceptions; Tool Diameter

Offsets (R+/-), and Radius vs. Diameter inputs.

Tool diameter offsets have no applications with turning tools, so this

functionality is not available while doing turning presets.

Input values can be either radius or diameter values. It is important to

be sure the units you are entering for the preset agree with the state

that the display is currently using. A diameter value is shown with a Ø

symbol. The state of the display can be changed using the RAD/DIA

soft key (available in both operating modes).

Radius/Diameter Soft Key

Drawings for lathe parts usually give diameter values. Wizard 411 can

display either the radius or the diameter for you. When the diameter is

being displayed, the diameter symbol (Ø) is shown next to the position

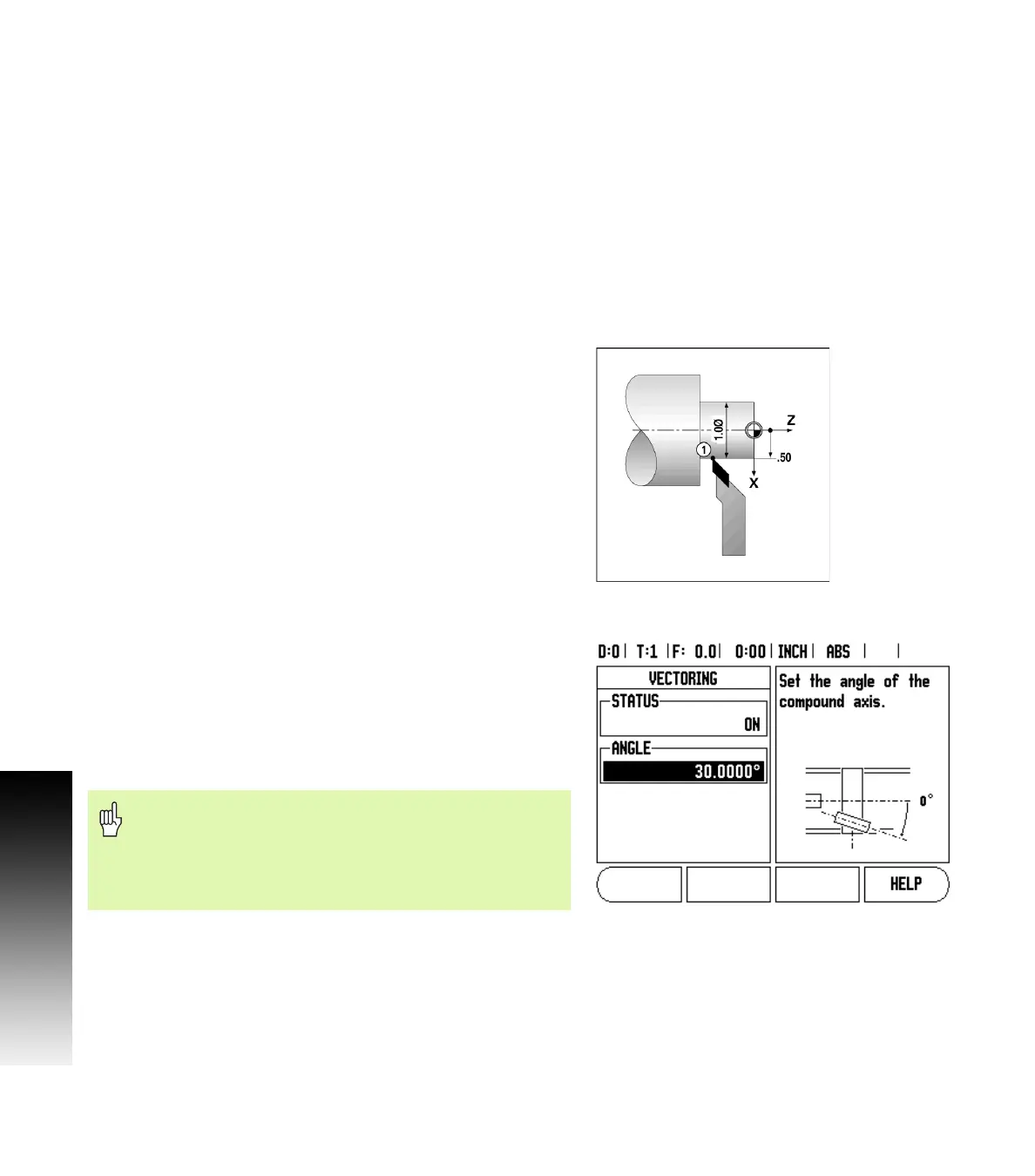

value. See Fig. I.35.

Example: Radius display, position 1, X = .50

Diameter display, position 1, X = Ø 1.0

Press the RAD/DIA soft key to switch between radius display and

diameter display.

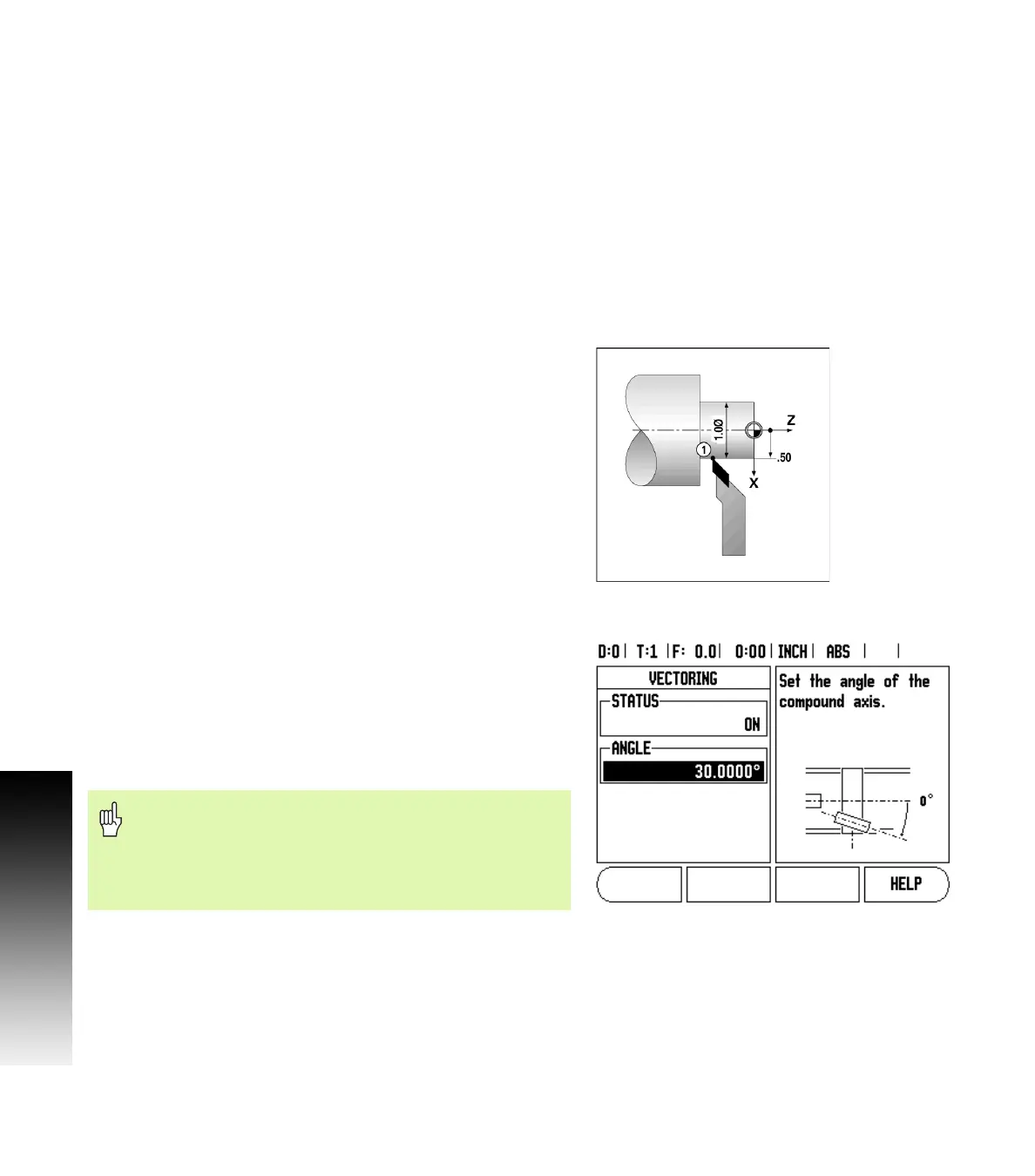

Vectoring

Vectoring breaks down the movement of the compound axis into the

crossfeed or longitudinal axes See Fig. I.36. If you are turning threads,

for example, vectoring lets you see the diameter of the thread in the

X-axis display, even though you are moving the cutting tool with the

compound axis handwheel. With vectoring enabled, you can preset

the desired radius or diameter in the X-axis, so that you can “machine

to zero”.

Press the VECTORING hard key.

Press the ON soft key to enable the vectoring feature.

Arrow down to the Angle field to enter the angle between the

longitudinal slide and top slide with 0° indicating the top slide is

moving parallel to the longitudinal slide. Press ENTER.

Fig. I.35 Workpiece for radius/diameter display

Fig. I.36 Vectoring

When vectoring is used, the top slide (compound) axis

encoder must be assigned to the bottom display axis. The

crossfeed component of movement of the axis will then

be shown in the top display axis. The longitudinal

component of movement of the axis will be shown in the

middle display axis.

Loading...

Loading...