22 I

I – 3 Turning Specific Operations

Datum Setting

See "Datum Setting" on page 8 for basic information. Datum settings

define the relationships between the axis positions and the display

values. For most lathe operations there is only one X-axis datum, the

center of the chuck, but it may be helpful to define additional datums

for the Z-axis. The table can hold up to 10 datum points. The easiest

way to set datum points is to touch a workpiece at a known diameter

or location, then enter that dimension as the value that the display

should be showing

...

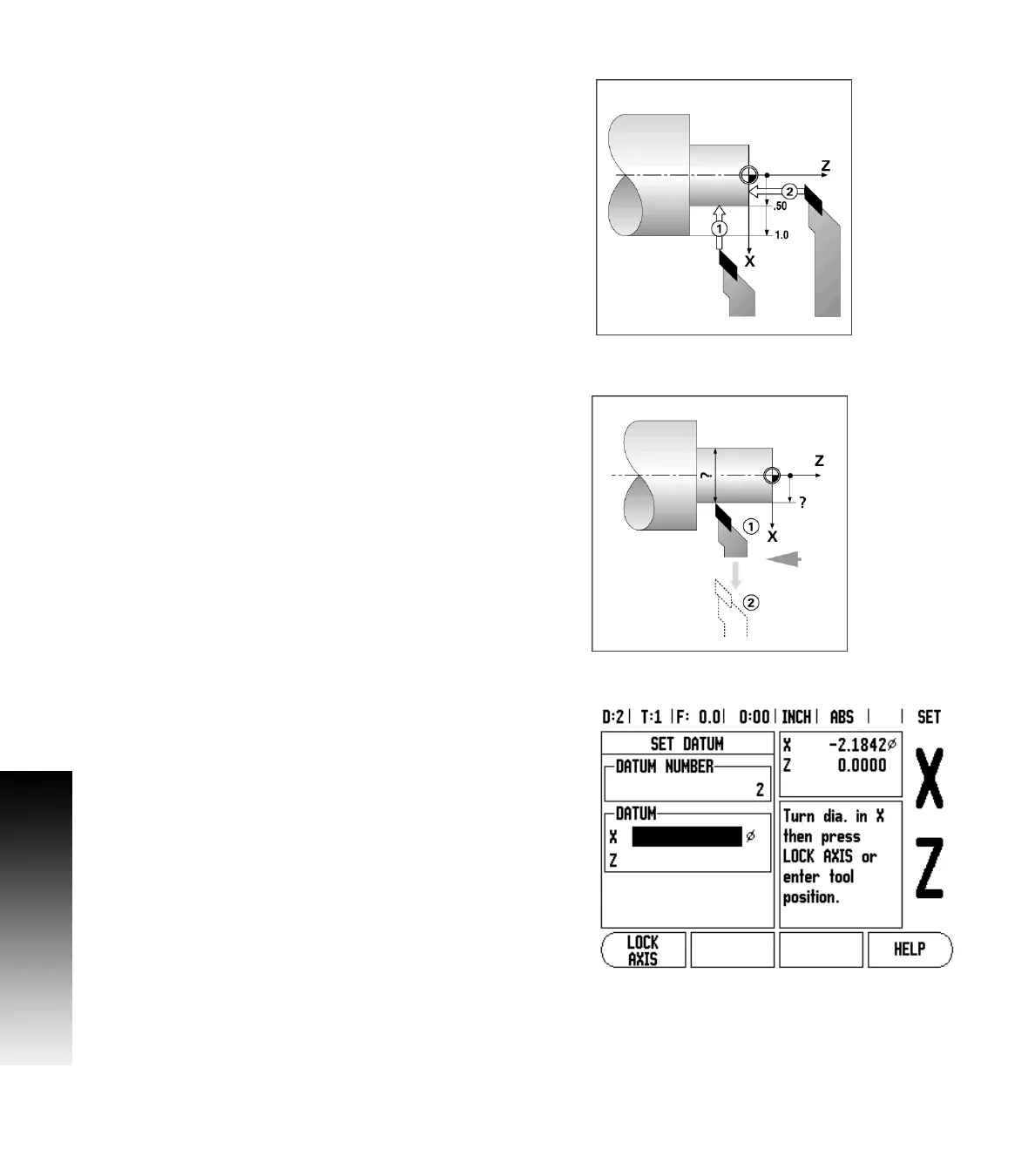

Example: Setting a workpiece datum. See Fig. I.30.

Preparation:

Call the tool data by selecting the tool which you are using to touch the

workpiece. Press the DATUM hard key. The cursor will be in the DATUM

NUMBER field. Enter the datum number and press the DOWN ARROW key

to go to the X-axis field. Touch the workpiece at point 1. Enter the

radius or diameter of the workpiece at that point.

Remember to ensure the Wizard 411 is in diameter display mode (Ø)

if you input a diameter value. Press the DOWN ARROW key to advance to

the Z axis.

Touch the workpiece surface at point 2. Enter the position of the tool

tip (Z= 0) for the Z coordinate of the datum. Press ENTER.

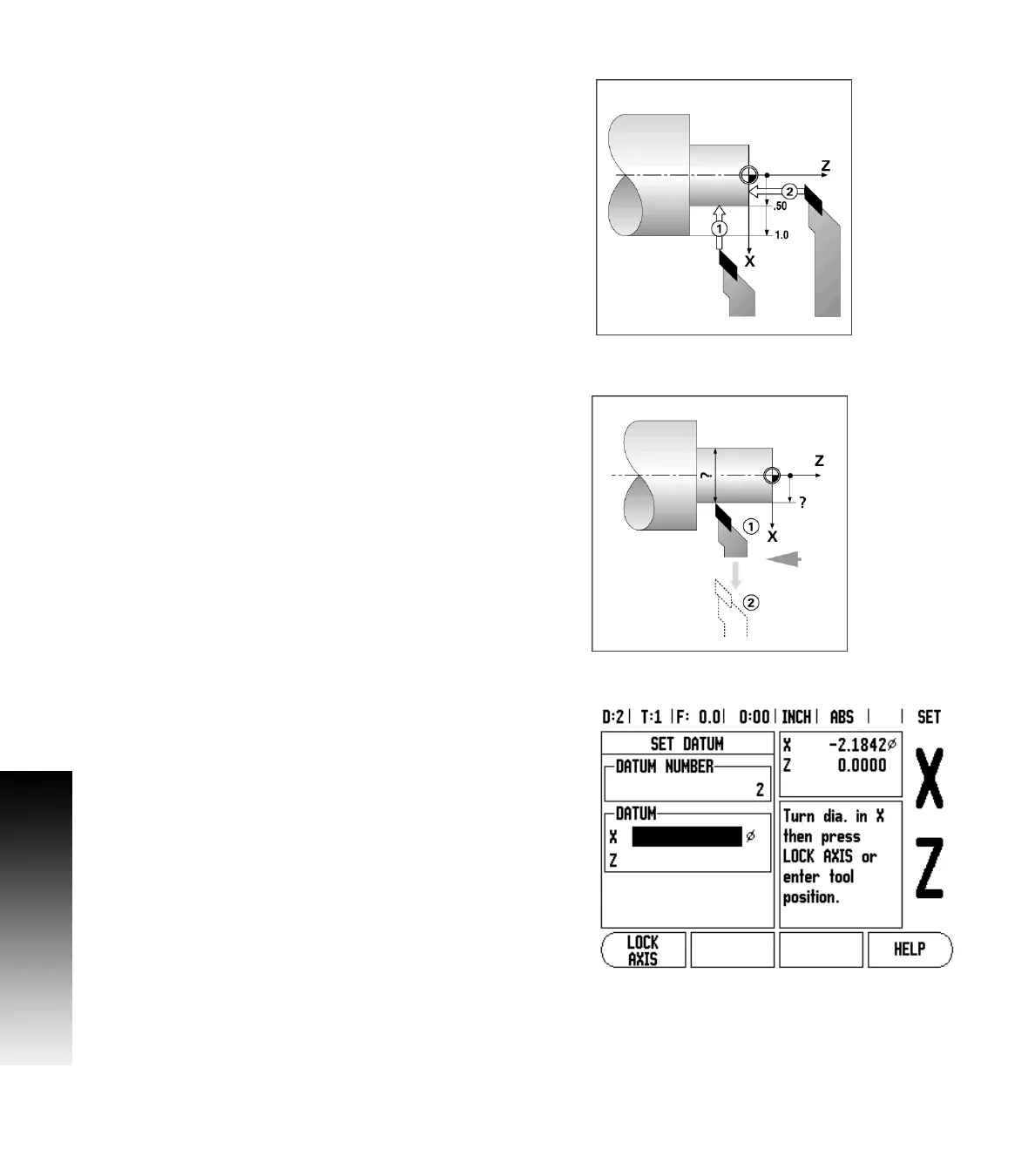

Setting Datums using LOCK AXIS Function

The LOCK AXIS function is useful for setting a datum when a tool is

under load and the diameter of the workpiece is not known. See Fig

Fig. I.31.

To use the LOCK AXIS function:

Press the DATUM hard key. The cursor will be in the DATUM NUMBER

field. Enter the datum number and press the DOWN ARROW key to go to

the X axis field. Turn a diameter in the X axis. Press the LOCK AXIS soft

key while the tool is still cutting. Retract from the current position.

Turn the spindle off and measure the workpiece diameter. Enter the

measured diameter, for example, 1.5” and press ENTER.

Fig. I.30 Setting a workpiece datum

Fig. I.31

Fig. I.32 Setting Datum using LOCK AXIS

Loading...

Loading...