Wizard 411 27

II – 1 Installation Setup

Enabling Z Coupling

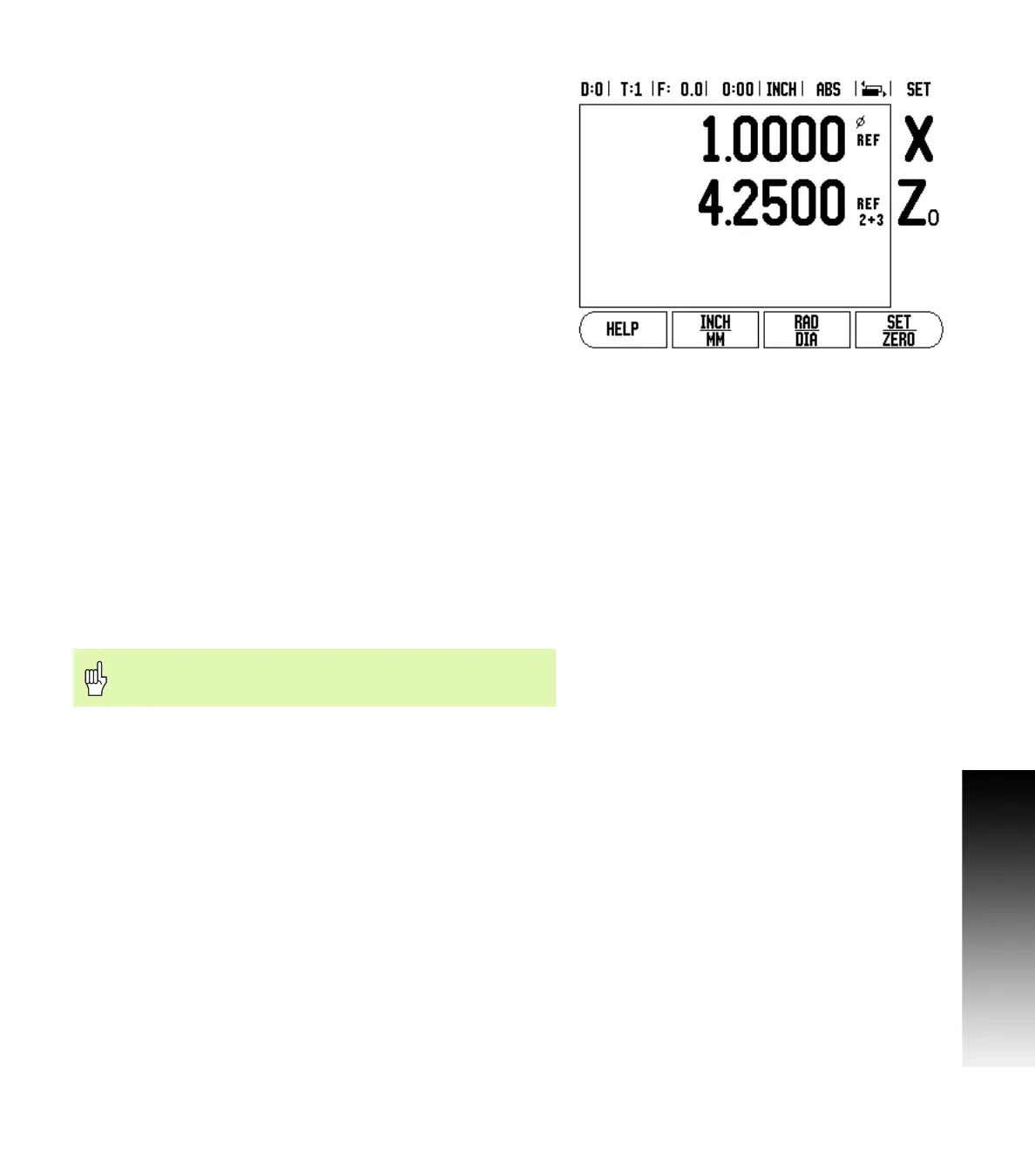

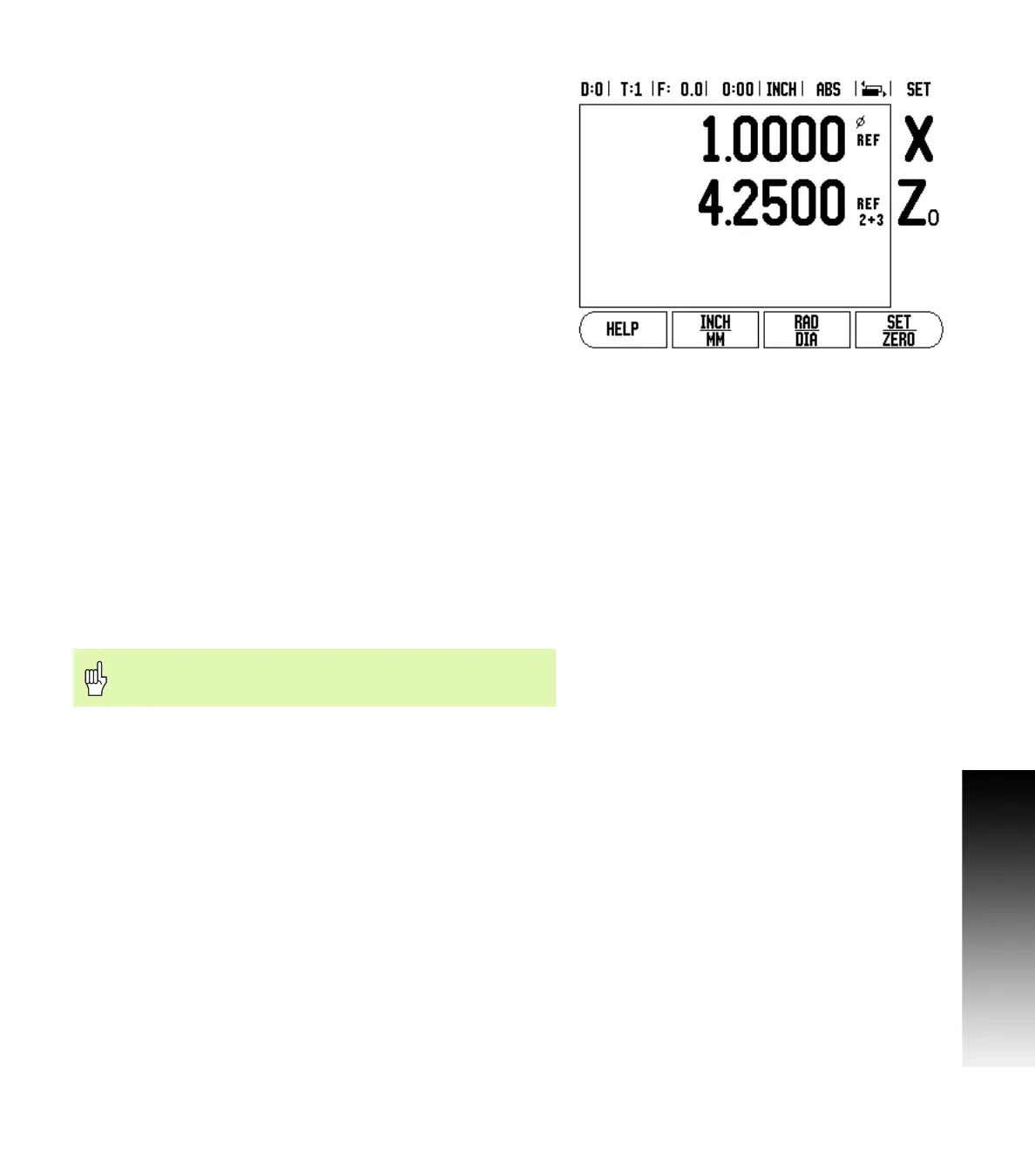

To couple the Z

0

and Z axis and have the result displayed on the Z

0

display, press and hold the Z

0

key approximately 2 seconds. The sum

of the Z positions will be displayed on the Z

0

display and the Z display

will be blanked. See Fig. II.4.

To couple the Z

0

and Z axis and have the result displayed on the Z

display, press and hold the Z key for approximately 2 seconds. The

sum of the Z positions will be displayed on the Z display and the Z

0

display will be blanked. The coupling is preserved in between power

cycles.

Moving either Z

0

or Z inputs will update the coupled Z position.

When a position is coupled, the reference mark for both encoders

must be found in order to recall the previous datum.

Disabling Z Coupling

To disable Z Coupling, press the axis key of the display that is blank.

The individual Z

0

and Z display positions will be restored.

Error Compensation

The distance a cutting tool travels, measured by an encoder, can in

certain cases, differ from the actual tool travel. This error can occur

due to ball screw pitch error or deflection and tilting of axes. This error

can either be linear or non-linear. You can determine these errors with

a reference measurement system, ex. gauge blocks, laser, etc. From

an analysis of the error it can be determined which form of

compensation is required, linear or non-linear error.

The Wizard 411 provides the opportunity to compensate for these

errors and each axis can be programmed separately with the

appropriate compensation.

Fig. II.4 Enabling Z Coupling

Error compensation is only available when using linear

encoders.

Loading...

Loading...