20 I

I – 3 Turning Specific Operations

I – 3 Turning Specific Operations

This section discusses operations specific to turning applications only.

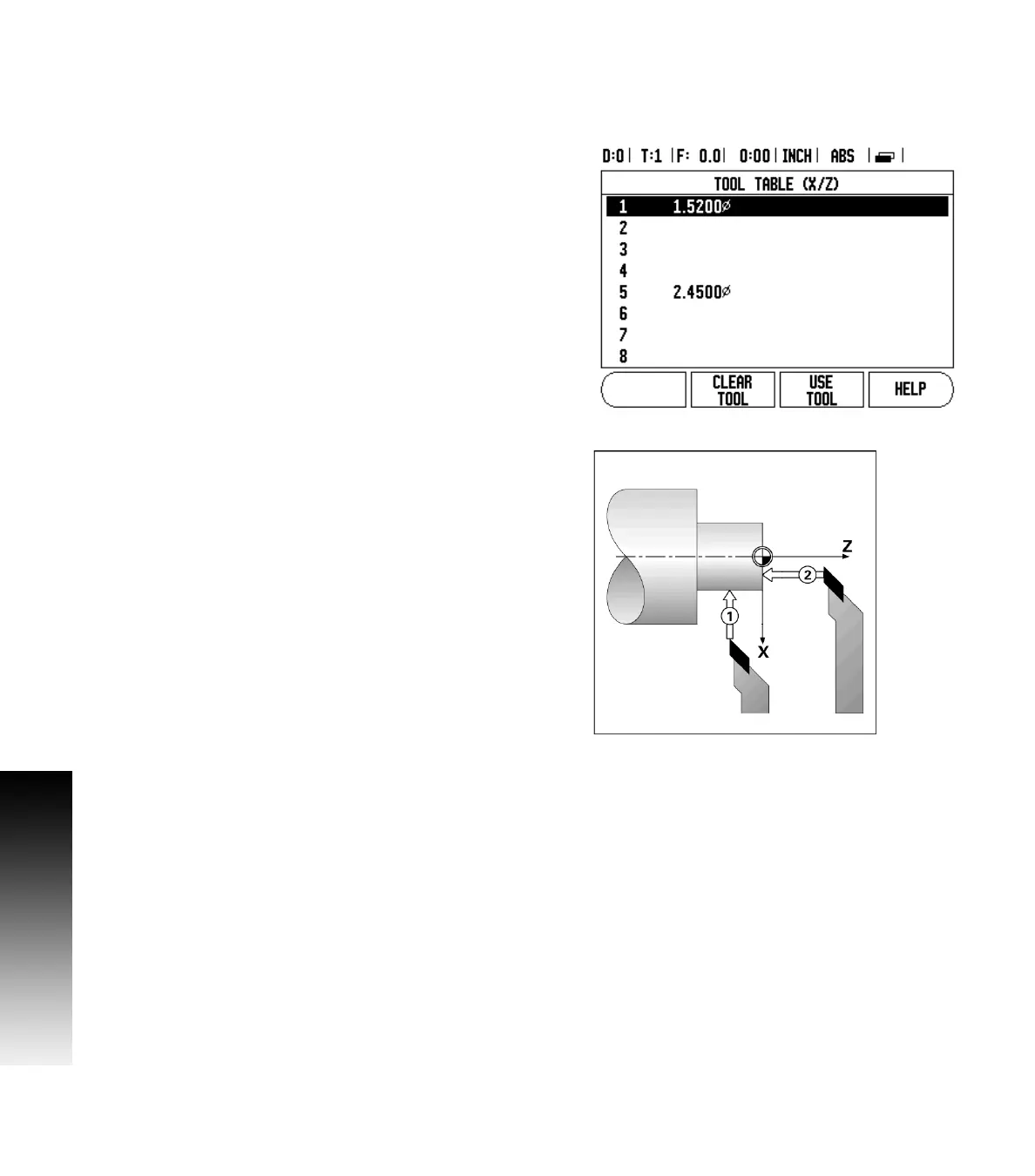

Tool Table

The Wizard 411 can store the dimensional offsets for up to 16 tools.

When you change a workpiece and establish a new datum, all tools are

automatically referenced from the new datum.

Before you can use a tool, you must enter its offset (the cutting edge

position). Tool offsets can be set using the TOOL/SET or LOCK AXIS

features. See the following examples for instructions on Tool

Offsetting (See Fig. I.26).

Tool Display Icon

The Ø icon is used to indicate that the displayed value is a diameter

value. No icon visible indicates that the display is a radius value.

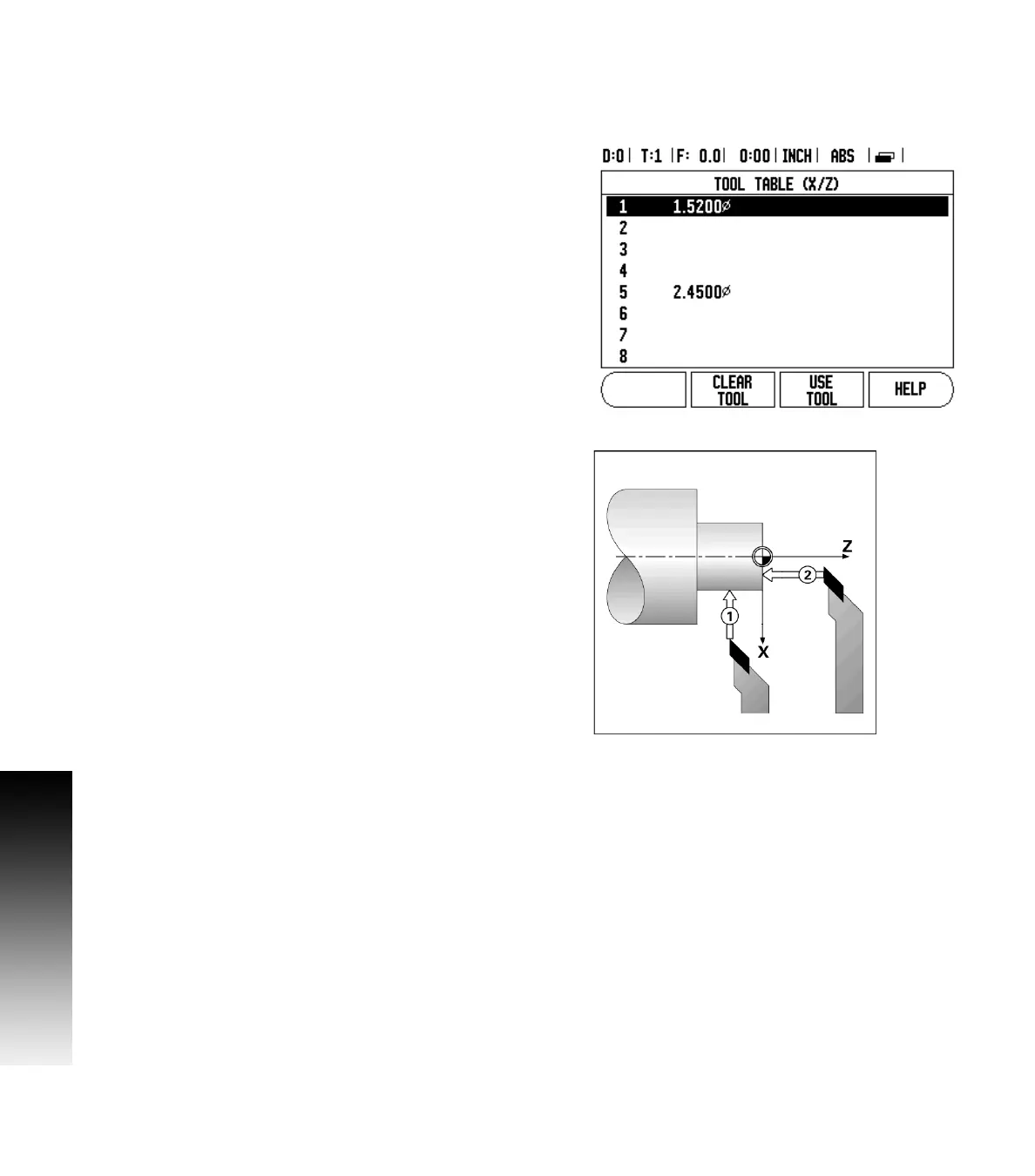

Setting Tool Offsets Example 1: Using TOOL/SET

The TOOL/SET operation can be used to set a tool’s offset using a tool

when the diameter of the workpiece is known. Touch the known

diameter in the X axis (1). Press the TOOL hard key. Scroll to the desired

tool. Press the ENTER key. Select the axis (X) key.

Enter the position of the tool tip, for example, X= .100.

Remember to ensure the Wizard 411 is in diameter display mode (Ø)

if you input a diameter value. Touch the workpiece face with the tool.

Cursor to the Z axis (2), then set the position display for the tool tip to

zero, Z=0. Press ENTER.

Fig. I.26 Tool table in turning

Fig. I.27

Loading...

Loading...