Training manual ALTEAS & GENUS ONE

Page. 50 of 88 Version 2V2.

6.7 COMBUSTION CONTROL SYSTEM AND GAS SETTINGS

The gas setting is done automatically by the PCB.

This is possible using the feed-back that came from the ionization current and adjusting the gas through the

gas valve.

No mechanical adjustments are required.

During the first ignition is mandatory do the Automatic calibration procedure (see par. 2.1 – First ignition

procedure).

During the normal working the system works continuously to check end if needs to correct the combustion

using electrode, PCB and gas valve.

6.7.1 Inlet gas pressure check

Switch on the boiler at the maximum power (using “FLUE CLEANER” function DHW

max power), check the inlet gas pressure using the inlet pressure test point. The supply

pressure must correspond to the value established in relation to the type of gas ,for

which the boiler is designed (refer to table below).

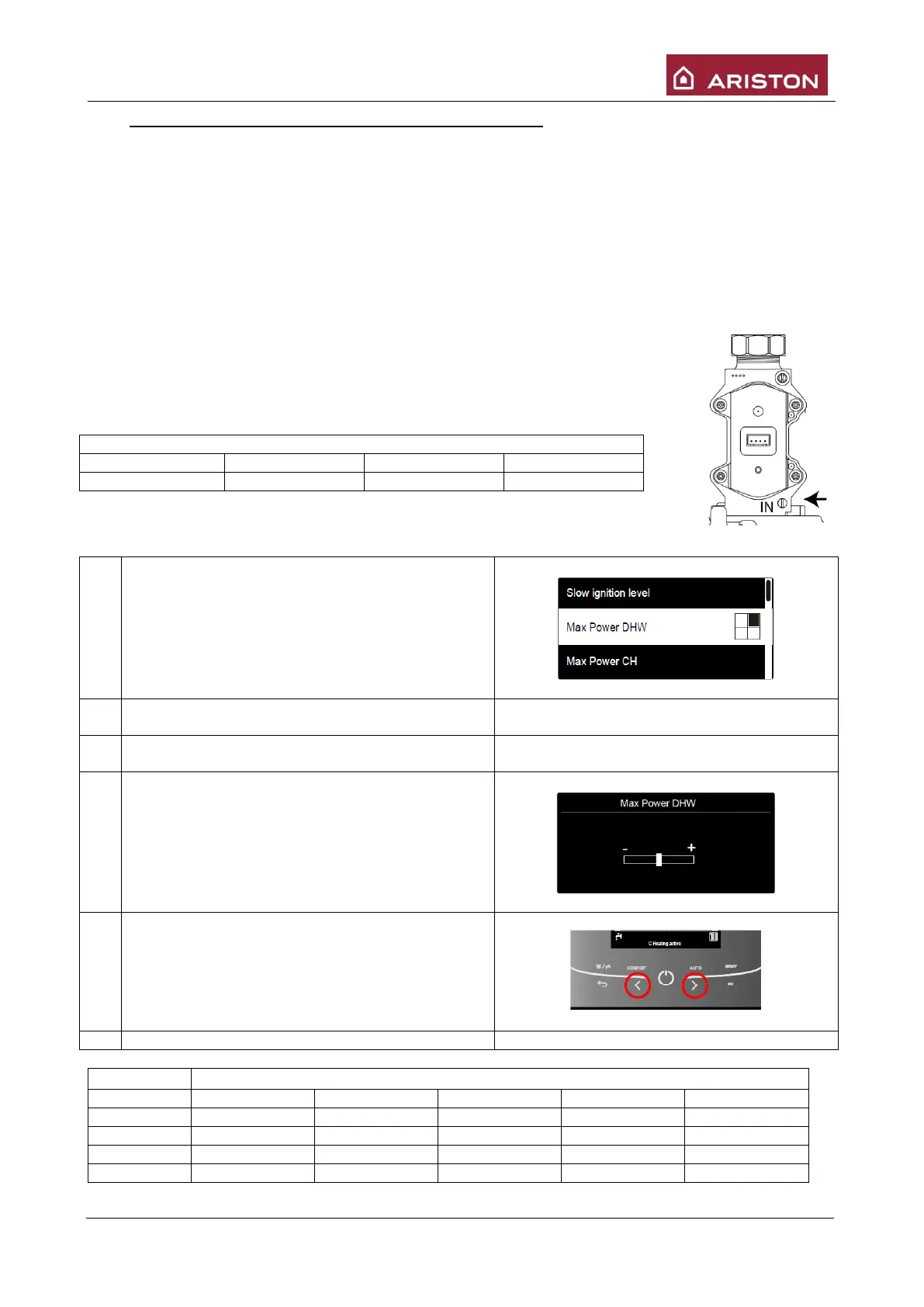

6.7.2 CO2 adjustment – DHW maximum power

Switch on the boiler at the maximum power (using

“FLUE CLEANER” function DHW max power)

Wait till the value of the CO2 on the exhaust

analyser is stable.

Compare the CO2 value with the values in the table

below.

If the CO2 value is not ok press “OK” button and the

display shows the adjustment bar.

Using the buttons “<” and “>” to adjust the CO2

value (it is possible modify the CO2 of a value

±0,5%).

Note: To see the CO2 variation it needs to finish

this procedure and perform 5 ignitions of the

boiler.

To save the new setting push the button “Ok”

N.B.: Values with casing closed.

Loading...

Loading...