On compressors equipped with a dryer bypass, fit the air outlet valve to the dryer bypass pipe.

7. Connect the condensate drain outlet(s) to a drain collector.

See section Condensate system.

The drain pipes to the drain collector must not dip into the water. If there is a risk for freezing, the pipes

must be insulated.

For draining of pure condensate water, install an oil/water separator which is available from Atlas Copco

as an option. See section OSCi

8. For compressors with a DD or a DD and PD filter: connect the automatic drain of the filters to a suitable

drain collector.

9. On water-cooled compressors, drain valves, shut-off valves and a regulating valve should be fitted by the

customer in the cooling water piping.

10. Provide labels, warning the operator that:

• The compressor may automatically restart after voltage failure (if activated, consult Atlas Copco).

• The compressor is automatically controlled and may be restarted automatically.

Initial start procedure

If the compressor has not run for the past 6 months, it is strongly recommended to improve

the lubrication of the compressor element before starting.

To do so:

1. Disconnect the inlet hose.

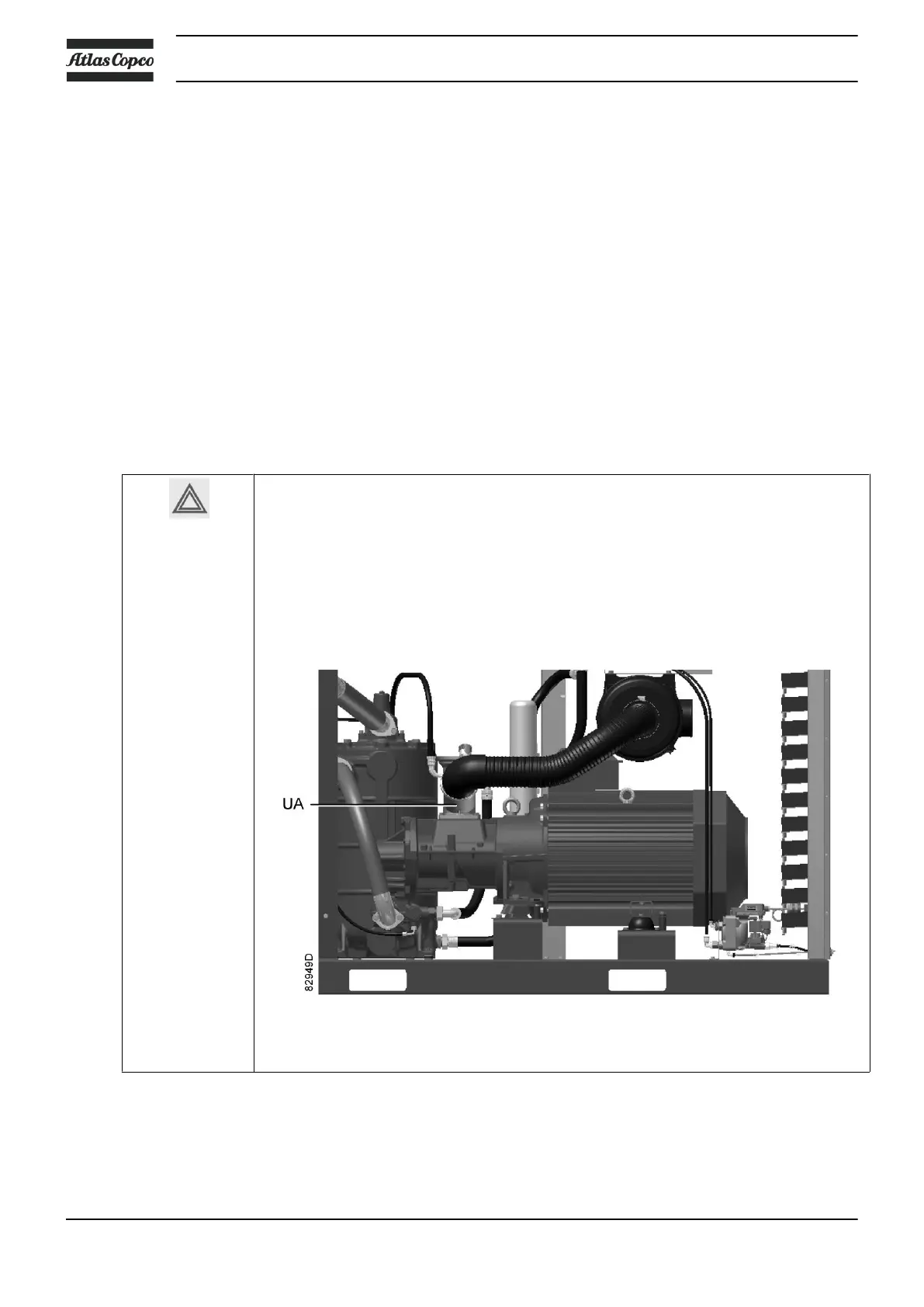

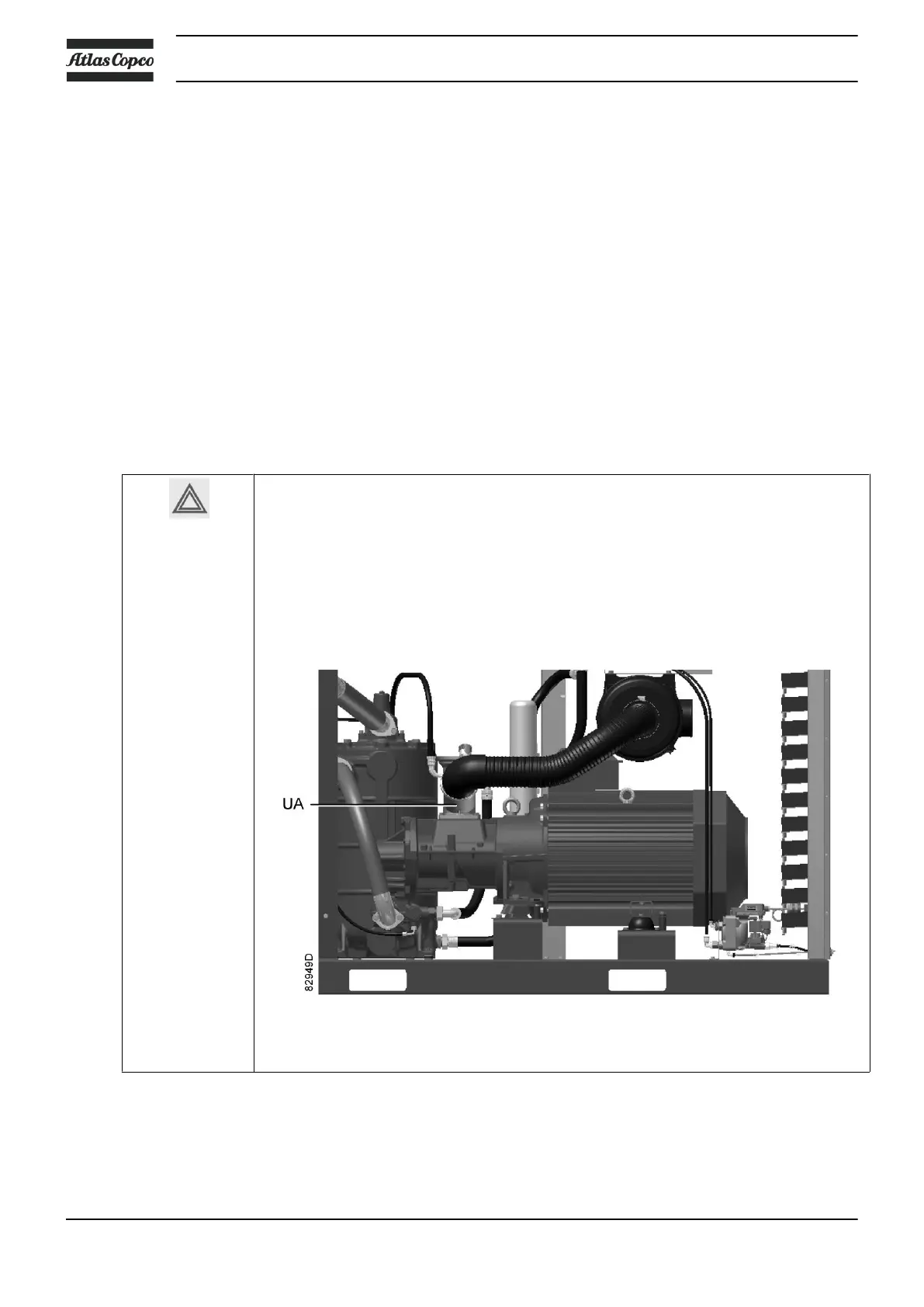

2. Remove the unloader (UA).

3. Pour approximately 0.75 l (0.20 US gal, 0.17 Imp gal) of compressor oil into the

compressor element inlet. For oil specifications, see section Oil specifications.

4. Reinstall the unloader and reconnect the inlet hose.

Make sure that all connections are tight.

Location of unloader

1. Check the oil level before starting.

The oil level should be between the oil filler neck (FC) and the top of the sight glass (Gl).

Instruction book

162 2920 7109 60

Loading...

Loading...