Instruction Manual

2954 2510 03 57

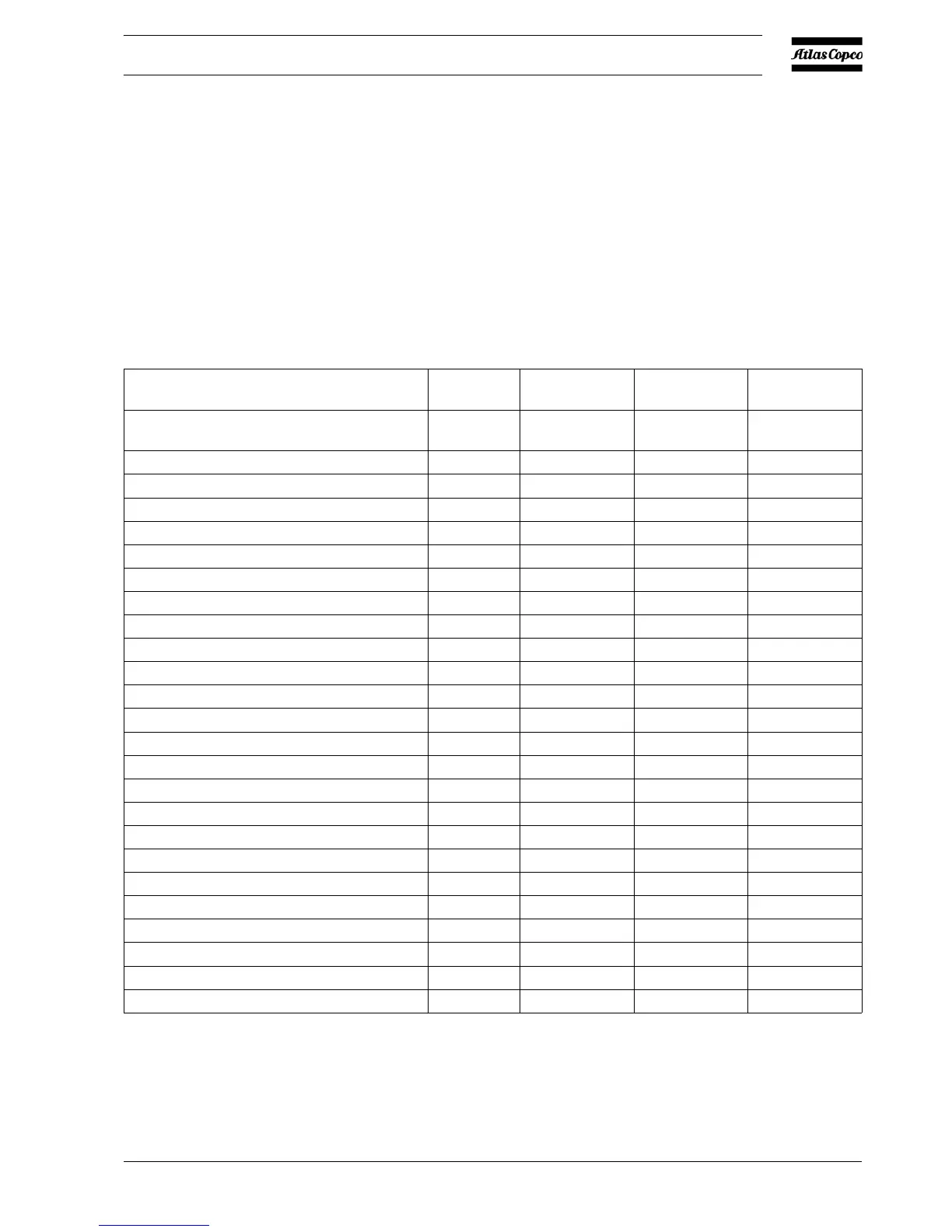

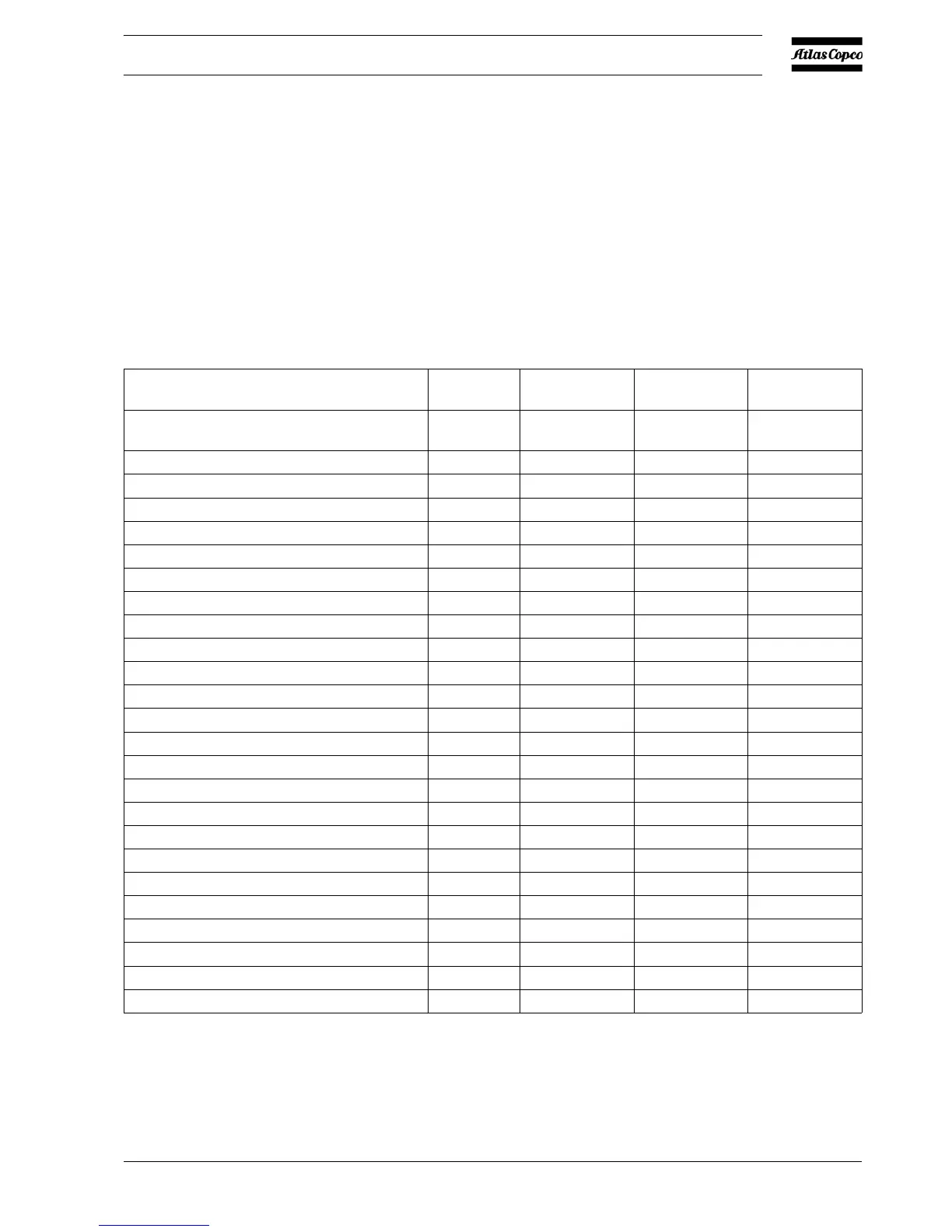

4.5 Preventive maintenance schedule for the compressor

The schedule contains a summary of the maintenance instructions. Read the respective section

before taking maintenance measures.

When servicing, replace all disengaged packings, e.g. gaskets, O-rings, washers.

For engine maintenance refer to Engine Operation Manual.

The maintenance schedule has to be seen as a guideline for compressors operating in a dusty

environment typical to compressor applications. Maintenance schedule can be adapted depending

on application, environment and quality of maintenance.

To be continued on page 58.

Maintenance schedule

Daily 50 hours after

initial start-up

Every 6 months

or 500 hours

Yearly or every

1000 hours

XRHS 506 - XRHS 1100 CD6,

XRVS 476 - XRVS 1000 CD6

supplied with

unit

2912 4432 05 2912 4432 06

Engine oil level Check

Condensate (11) Drain

Compressor oil level Check

Coolant level Check

Air filter vacuator valves Empty

Fuel filter water drain Drain

ABS vessel drain Drain

Electrolyte level and terminals of battery Check Check Check

Tyre pressure Check Check Check

Leaks in air-, oil- or fuel system (13) Check Check Check

Oil cooler Clean Clean

Radiator Clean Clean

Intercooler Clean Clean

Torque of wheel nuts Check Check Check

Brake system (if installed) Check/Adjust Check/Adjust Check/Adjust

Safety valve (10) Test

Door hinges Grease Grease

Towing eye shaft or ball coupling and shaft Grease Grease

Bleed-off valve unloader Replace

Oil stop valve Clean

Rubber flexibles (13) Check

Shut-down switches Check

Pressure drop over oil separator element

(2) Replace

Fan V-belts (3) Adjust Adjust Adjust

Loading...

Loading...