31

function and strengthen wear-out of the engine.

Cleaning the sump

Drain off the engine oil thoroughly.

Disassemble each parts

Clean each part respectively.

Fuel with the appointed engine oil.

This work only can be done by professional stuff, please

have your sump cleaned at the authorized service station.

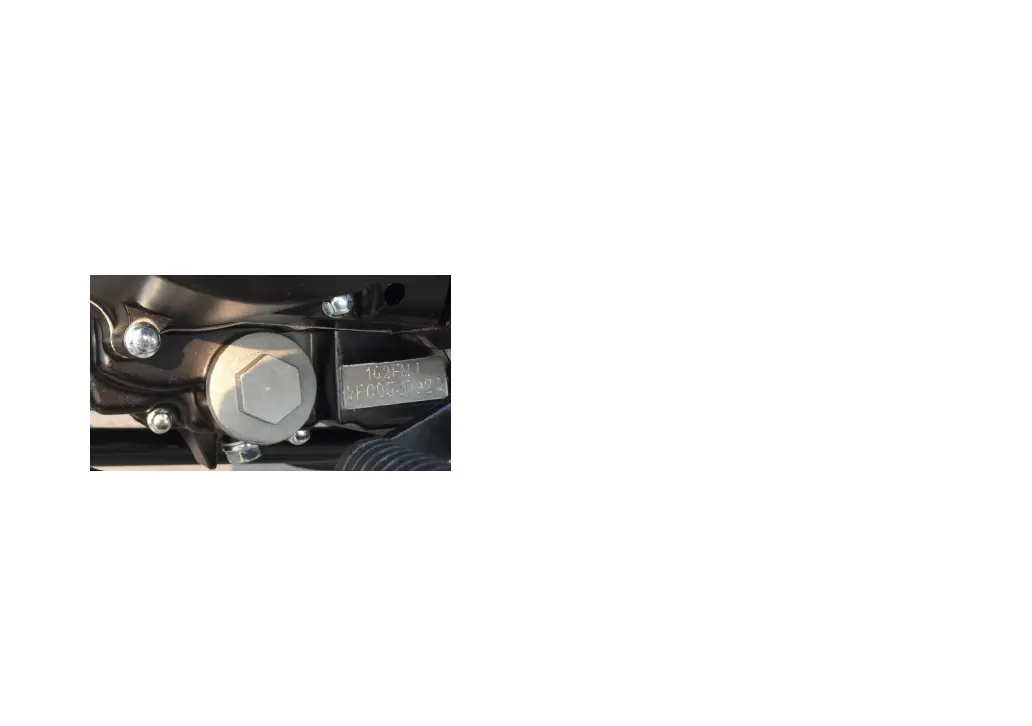

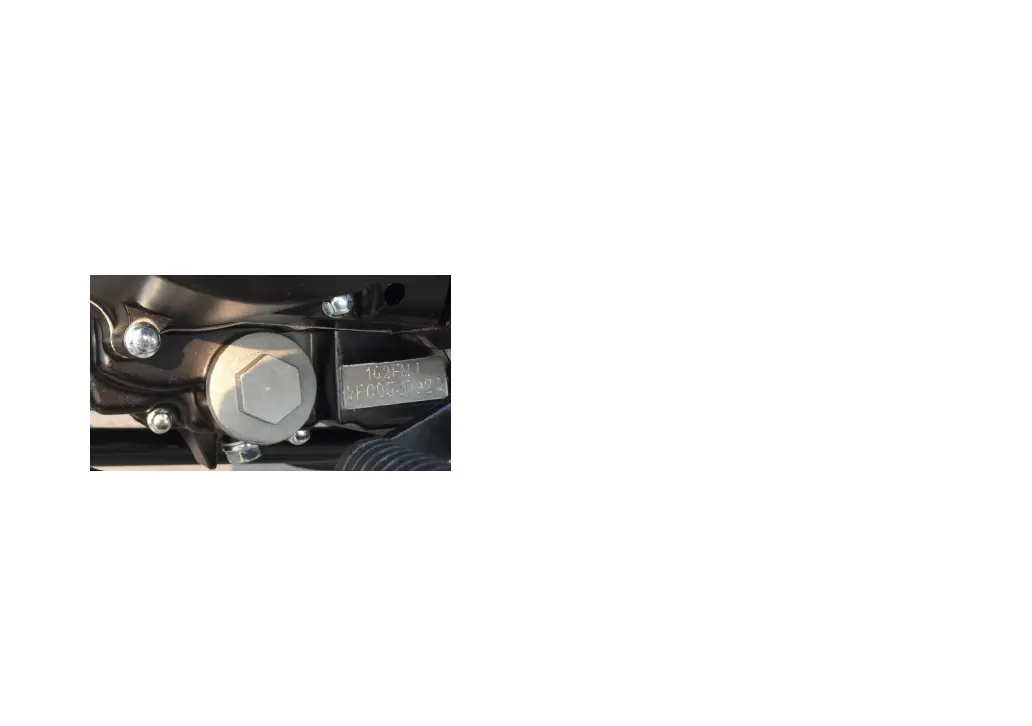

Cleaning oil filter

The oil drain plug (filtering net cover) remove

Out the filter net

The filtering net is dross clean

According to the original machine assembly reduction

3. Valve clearance

The valve clearance should be inspected and adjusted on a cold

engine by the following procedures:

Remove the caps of the central port and the ignition timing ob-

servation port on the left crankcase cover.

Remove the caps of the valves on the cylinder head.

Turn the nut of the flywheel clockwise until the engraved "T" mark

on the flywheel aligns with the engraved line on the top of the

crankcase cover, and both intake and exhaust rocker arms do not

move but stop at their loosest position. This indicates that the

piston is in its top dead center position of the compressing stroke.

If the "T" mark is near the proper position but the rocker arms will

move when the flywheel rotates within a small angle, the flywheel

is not on the compression stroke but exhaust/intake stroke. In this

case, continue to turn the flywheel clockwise 360 degrees to

reach top dead center position of the compressing stroke, where

the valve clearance can be adjusted.

Check the valve clearance by inserting a clearance gage into the

gap between adjusting screw and the end of the valve.

Specified valve clearance: 0.10-0.12mm

If valve clearance adjustment is needed, loosen the locking nut

Loading...

Loading...