8. Rotate multi-turn actuator until alignment of the mounting holes.

9. Reinstall multi-turn actuator with screws [3].

10. Reinstall screws [3] crosswise with a torque according to table.

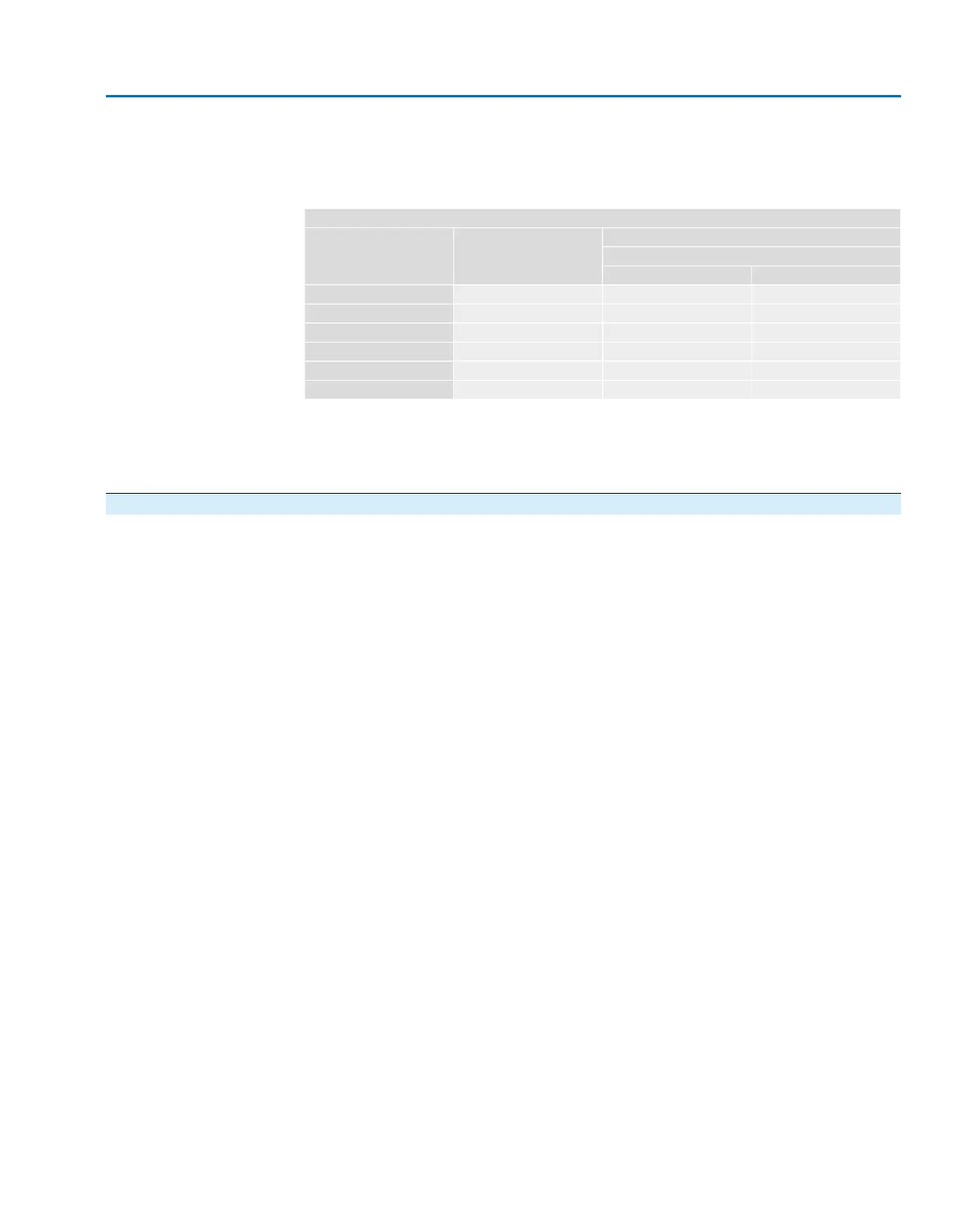

Table 3:

Tightening torques for screws

Tightening torque ft-lb [Nm]M threadsUNC threads

Strength class

A2-808.8

7 [10]8 [11]M61/4"

18 [24]18 [25]M85/16"

35 [48]38 [51]M103/8”

60 [82]64 [87]M121/2"

148 [200]158 [214]M165/8”

289 [392]318 [431]M203/4”

11. Turn multi-turn actuator with handwheel in direction OPEN until valve flange and

output drive A are firmly placed together.

12. Tighten fastening screws [5] between valve and output drive type A crosswise ap-

plying a torque according to table.

4.3.2. Output drive types B

Application

●

For rotating, non-rising valve stem

●

Not capable of withstanding thrust

Design

Connection between hollow shaft and valve or gearbox via output drive sleeve fixed to

the hollow shaft of the multi-turn actuator via retaining ring.

Changing output drive sleeve allows later retrofitting to a different output drive type.

●

Output drive type B: Output drive sleeve with bore according to DIN 3210

●

Output drive types B1 – B4: Output drive sleeve with bore according to EN ISO

5210

15

SAEx 07.2 – SAEx 16.2 / SAREx 07.2 – SAREx 16.2

Assembly

Loading...

Loading...