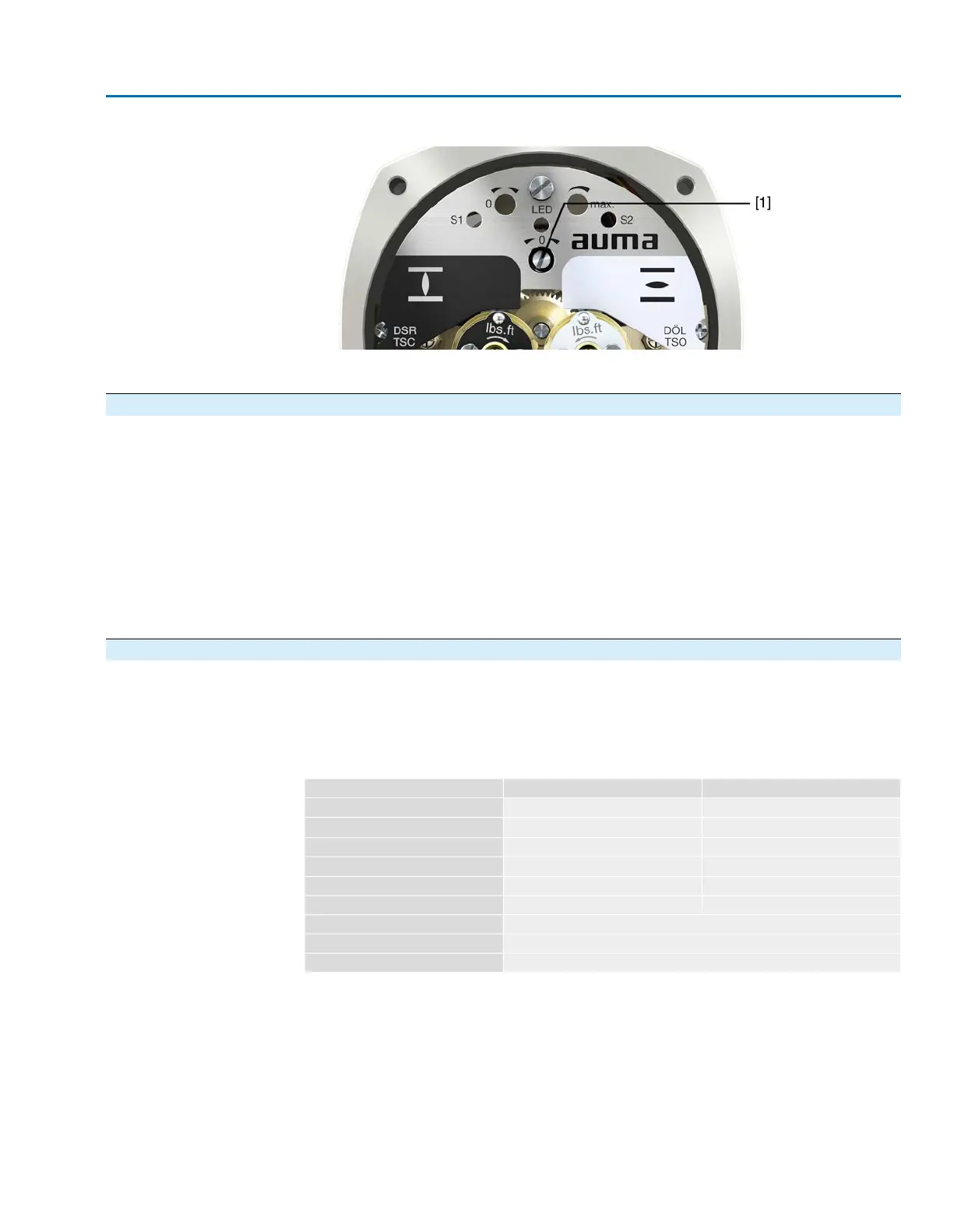

Figure 26: View on control unit

[1] Potentiometer

9.7.1. Potentiometer setting

Information Due to the ratio of the reduction gearing, the complete resistance range/stroke is not

always covered.Therefore, external adjustment (setting potentiometer) must be provided.

1. Move valve to end position CLOSED.

2. Turn potentiometer [1] clockwise to the stop.

➥

End position CLOSED corresponds to 0 %

➥

End position OPEN corresponds to 100 %

3. Turn potentiometer [1] slightly in opposite direction.

4. Perform fine-tuning of the zero point at external setting potentiometer (for remote

indication).

9.8. RWG electronic position transmitter

— Option —

RWG electronic position transmitter records the valve position. On the basis of the actual

position value measured by the potentiometer (travel sensor), it generates a current

signal between 0 – 20 mA or 4 – 20 mA.

Technical data

Table 10: RWG 4020

2-wire system3-wire and 4-wire systemsData

4 – 20 mA0 – 20 mA, 4 – 20 mAOutput current I

a

14 V DC + (I x R

B

), max. 30 V24 V DC (18 – 32 V)Power supply U

V

1)

20 mA24 mA at 20 mA output currentMax. current consumption

(U

V

– 14 V)/20 mA

600 Ω

Max. load R

B

0.1 %/V0.1 %/VImpact of power supply

0.1 %/100 Ω0.1 %/(0 – 600 Ω)

Load influence

< 0.3 ‰/KTemperature impact

–76 °F to 176 °F (–60 °C to +80 °C)Ambient temperature

2)

5 kΩ

Transmitter potentiometer

Power supply possible via: AC, AM controls or external power supply1)

Depending on temperature range of the actuator: Refer to name tag2)

Setting components

The RWG is housed in the actuator switch compartment.The switch compartment must

be opened to perform any settings. Refer to <Switch compartment: open>.

Setting is made via three potentiometers [1], [2] and [3].

37

SAEx 07.2 – SAEx 16.2 / SAREx 07.2 – SAREx 16.2

Commissioning

Loading...

Loading...