11. Servicing and maintenance

Damage caused by inappropriate maintenance!

→

Servicing and maintenance must be carried out exclusively by suitably qualified

personnel having been authorized by the end user or the contractor of the plant.

Therefore, we recommend contacting our Service.

→

Only perform servicing and maintenance tasks when the device is switched off.

AUMA

Service & Support

AUMA offers extensive service such as servicing and maintenance as well as customer

product training. For the relevant contact addresses, please refer to <Addresses> in this

document or to the Internet (www.auma-usa.com)

11.1. Preventive measures for servicing and safe operation

The following measures are required to ensure safe device operation:

Every 6 months after commissioning and then every year

●

Carry out visual inspection:

Cable entries, cable glands, blanking plugs, etc. have to be checked for correct

tightness and sealing.

Consider torques according to manufacturer's details.

●

Check fastening screws between actuator and gearbox/valve for tightness. If re-

quired, fasten screws while applying the fastening torques as indicated in chapter

<Assembly>.

●

When rarely operated: Perform test run.

●

For devices with output drive A: Press in suitable EP multi-purpose grease on

mineral oil base at the grease nipple with a grease gun.

●

Lubrication of the valve stem must be done separately.

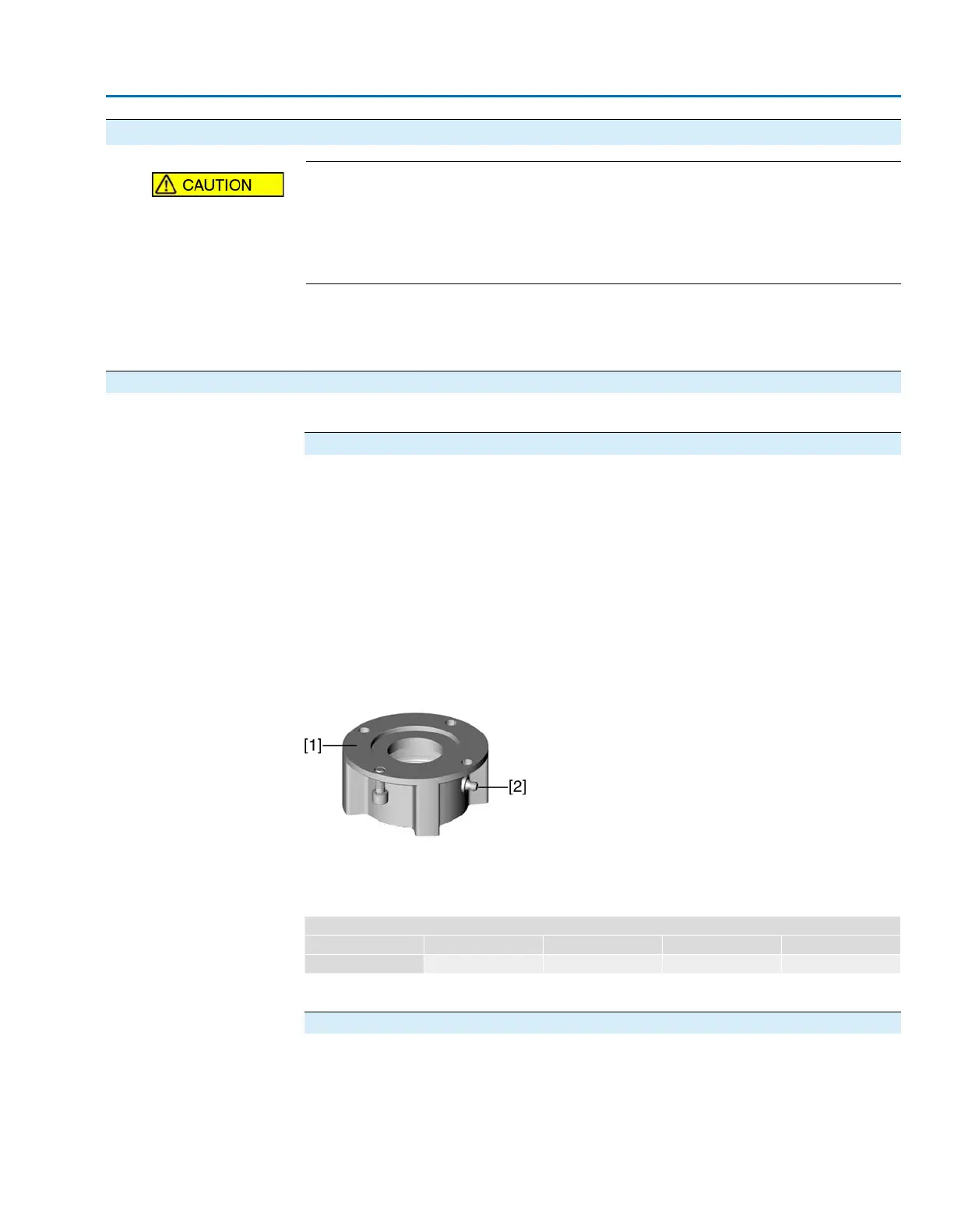

Figure 29: Output drive A

[1] Output drive A

[2] Grease nipple

Table 12:

Grease quantities for bearing of output drive type A

A 16.2A 14.2A 10.2A 07.2Output drive

10531.5Quantity [g]

1)

For grease at density r = 0.9 kg/dm³1)

For enclosure protection NEMA 4X/6P

After continuous immersion:

●

Check actuator.

●

In case of ingress of water, locate leaks and repair, dry device correctly and check

for proper function.

43

SAEx 07.2 – SAEx 16.2 / SAREx 07.2 – SAREx 16.2

Servicing and maintenance

Loading...

Loading...