Page D–6 Stellar

®

SR55 Series Soft Starter User Manual – 1st Ed, Rev F – 09/18/2019

Appendix D: Sizing an SR55 Soft Starter

deraTing examples

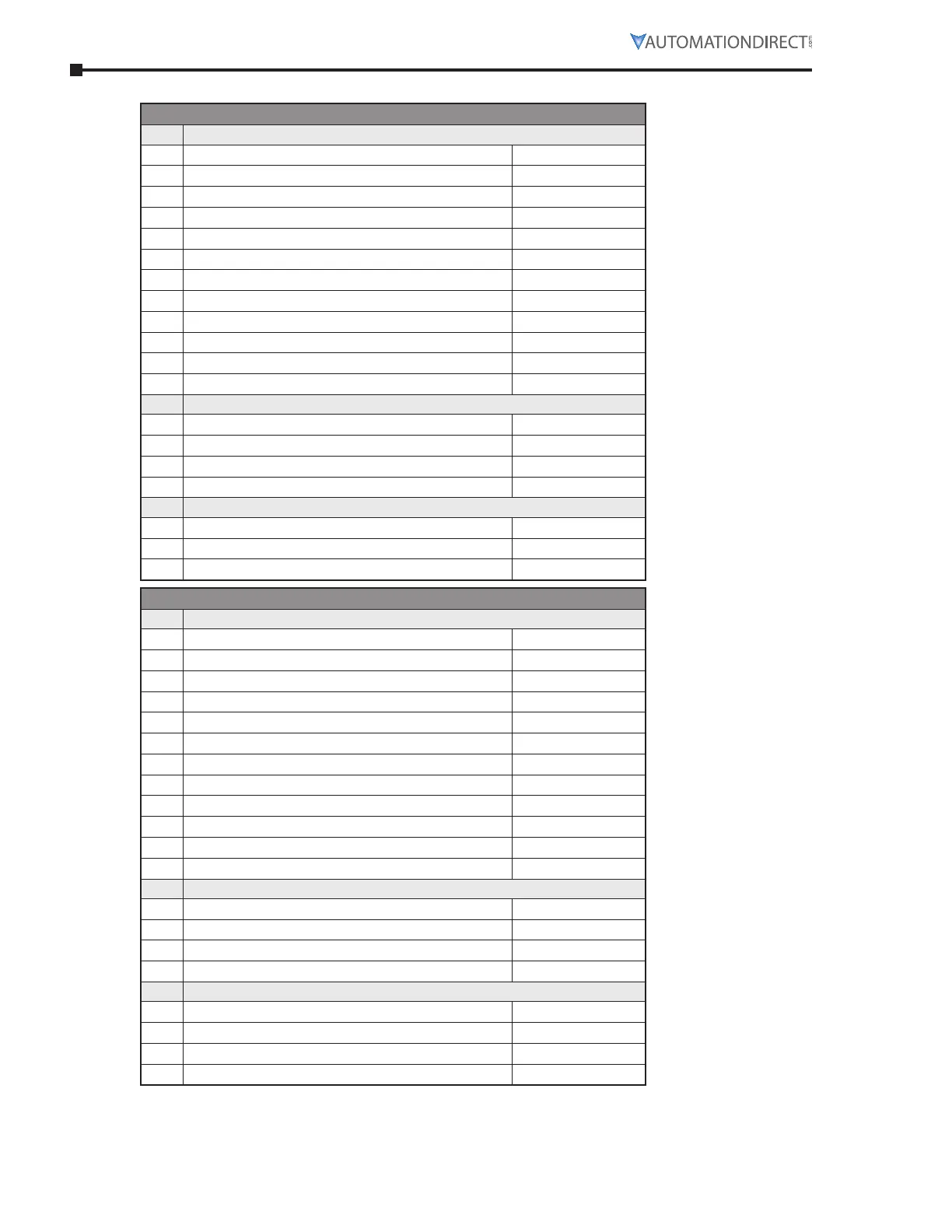

Example 1: SR55 Selection and Configuration

Step SR55 Selection

1 Application Loaded Conveyor

2 Trip Class 20

3 Duty 90%

4 In-Line or In-Delta In-Line

5 Ambient Temperature 40°C

6 Altitude 1000m

7 Full Motor Load Current 80A

8 Current Limit 4 x 80A = 320A

9 Number of Starts/Hour 10

10 Deration Factor (from Fig.2) 0.83

11 SR55 (A) = Motor FLC / Deration Factor 96A

12 Determine SR55 from Sizing Guide SR55-096

Step SR55 Configuration

1 Select Application (Auto Setup)

2 Leave Motor Current 100A (maximum) (Auto Setup)

3 Set Start Current Limit to 320A (400% of motor FLC) (Start Current Limit)

4 Set Overload Level to 88A (110% of motor FLC) (Overload Settings)

Step SR55 Alternative Configuration

1 Set Application (Auto Setup)

2 Set Motor Current to 80A (Auto Setup)

3 Warm Trip Time will be reduced to Trip Class 10 value (320A for 13s)

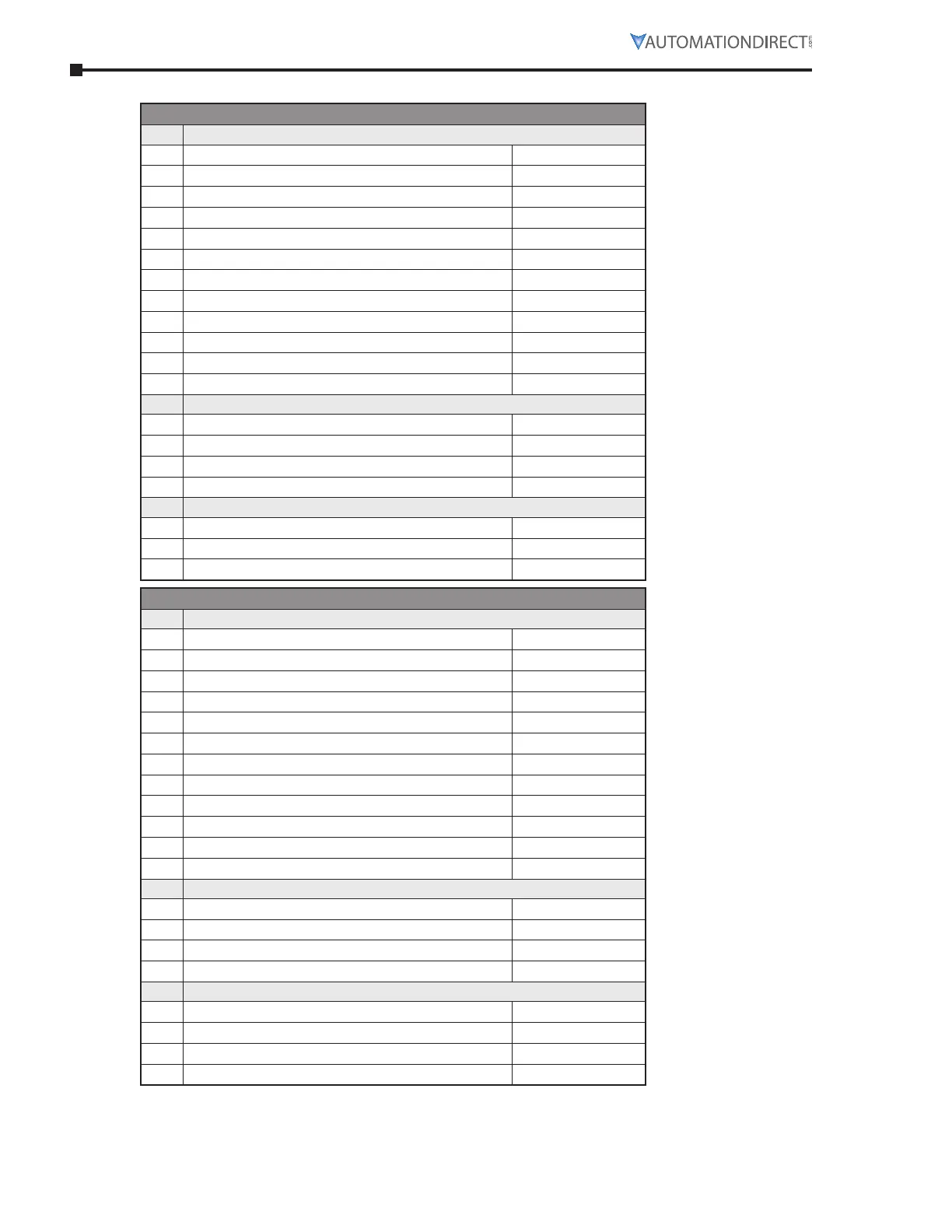

Example 2: SR55 Selection and Configuration

Step SR55 Selection

1 Application Agitator

2 Trip Class 10

3 Duty 90%

4 In-Line or In-Delta In-Line

5 Ambient Temperature 40°C

6 Altitude 1000m

7 Full Motor Load Current 66A

8 Current Limit 3.5 x 66A = 231A

9 Number of Starts/Hour 20

10 Deration Factor (from Fig.2) 0.66

11 SR55 (A) = Motor FLC / Deration Factor 100A

12 Determine SR55 from Sizing Guide SR55-124

Step SR55 Configuration

1 Select Application (Auto Setup)

2 Leave Motor Current 100A (maximum) (Auto Setup)

3 Set Start Current Limit to 231A (350% of motor FLC) (Start Current Limit)

4 Set Overload Level to 72A (110% of motor FLC) (Overload Settings)

Step SR55 Alternative Configuration

1 Set Application (Auto Setup)

2 Set Motor Current to 66A (Auto Setup)

3 Set Trip Class to 30 (Overload Settings)

4 Warm Trip Time will be reduced to Trip Class 10 value (231A for 17s)

Loading...

Loading...