Page 3–4 Stellar

®

SR55 Series Soft Starter User Manual – 1st Ed, Rev F – 09/18/2019

Chapter 3: Configuration and Parameters

AuTo seTup pRoceduRe – pARAmeTeR seTTINGs

Choose “Auto” setup from the “Setup Wizard” or from the “Home” menu, and set the following

parameter groups:

1) Application

2) Motor Current Rating

3) Control Method

4) Digital Input Voltage

The SR55 will automatically set the rest of the parameters as shown in the following table:

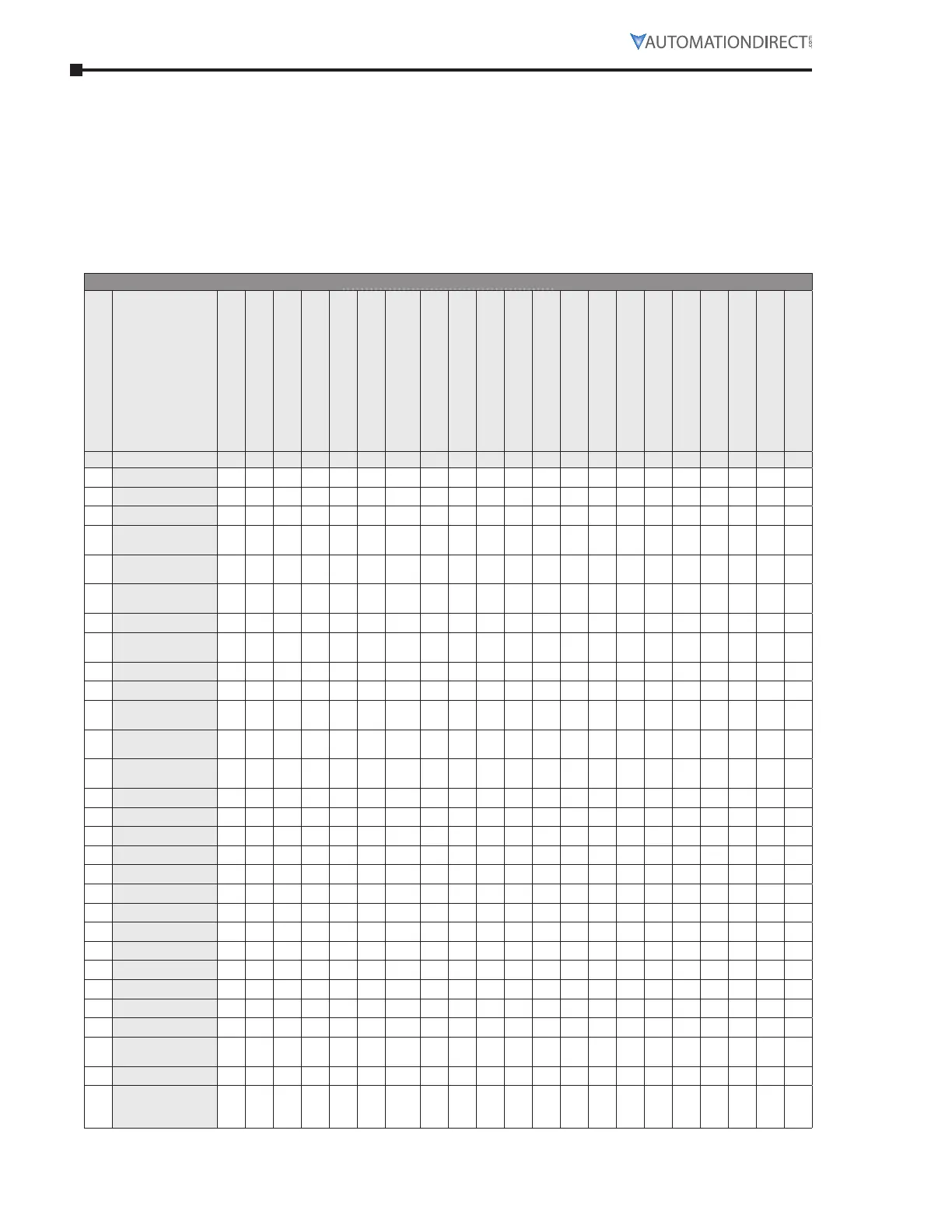

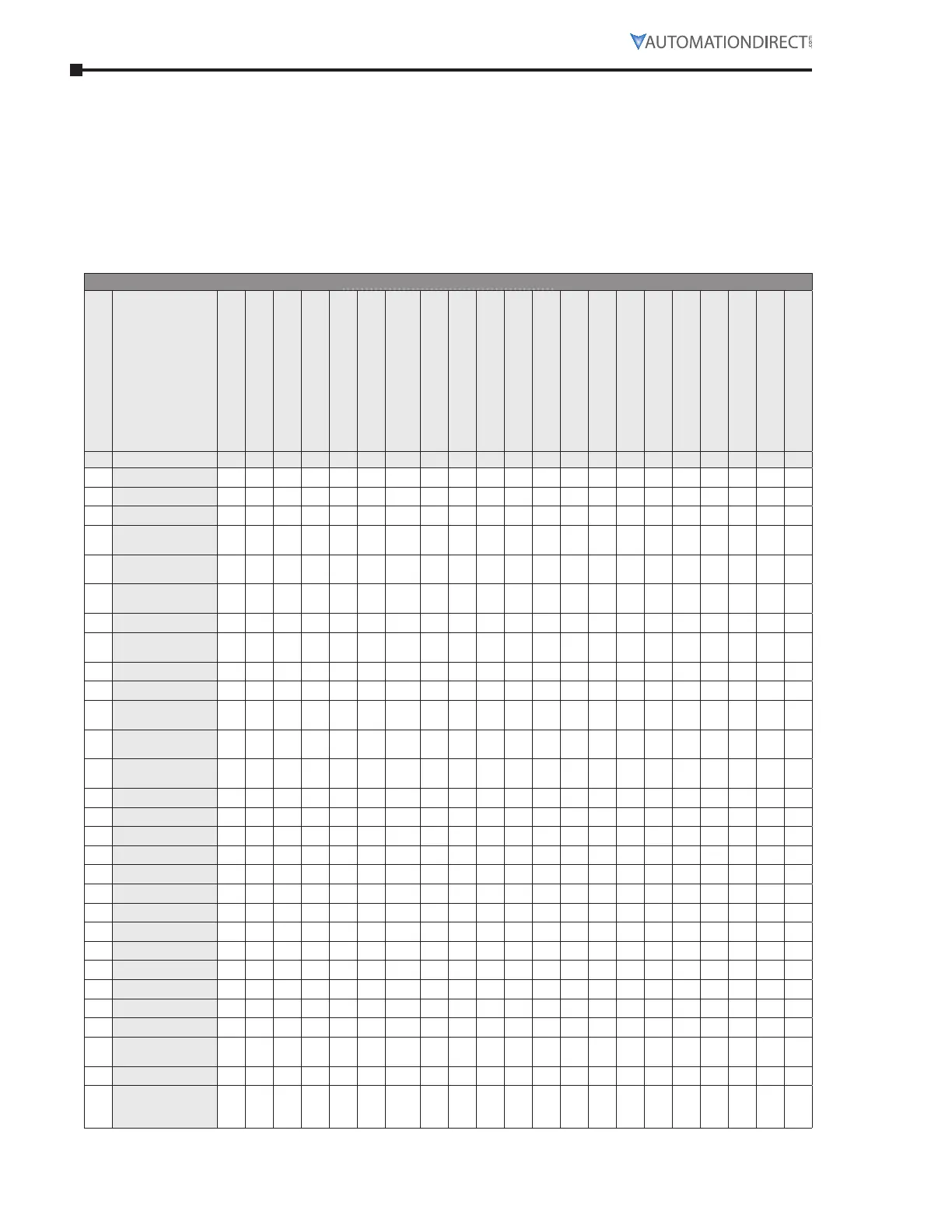

Auto Setup Parameter Settings

# Application

Start pedestal

Stop pedestal

Start time

Soft stop time

Trip Class

Current limit level

Current limit time

Optimize rate

Auto pedestal

Auto End Start 2

Auto End Start 1

Auto End 3

Delta Operation

Auto stop

Soft stop smoothing

spare

Auto ramp

Auto end stop

Impact load

Current limit - stopping

Current limit time - stopping

– Unit % % s s – FLC s – En En En En En En En En En En En FLC s

0 Default 20 10 10 0 10 3�5 30 5 0 0 0 1 1 0 0 0 0 0 0 8 2

1 Heavy 40 10 10 0 20 4 40 5 1 0 1 1 1 0 0 0 0 0 0 8 2

2 Agitator 30 10 10 0 10 3�5 25 5 1 0 1 1 1 0 0 0 0 0 0 8 2

3

Compressor -

Centrifugal

35 10 15 0 20 3�5 25 5 1 0 1 1 1 0 0 0 0 0 0 8 2

4

Compressor -

Reciprocating

45 10 15 0 20 3�5 25 15 1 0 1 1 1 0 0 0 0 0 0 8 2

5

Compressor -

Screw

40 10 15 0 20 3�5 25 5 1 0 1 1 1 0 0 0 0 0 0 8 2

6 Compressor - Vane 35 10 7 0 10 3�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

7

Compressor -

Scroll

35 10 7 0 10 3�5 25 15 1 0 1 0 1 0 0 0 0 0 0 8 2

8 Ball mill 40 10 10 0 20 5�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

9 Centrifuge 40 10 10 0 30 2�5 300 5 1 0 1 0 1 0 0 0 0 0 0 8 2

10

Bow Thruster -

Zero Pitch

10 10 10 0 10 2�5 25 5 1 1 0 1 1 0 0 0 0 0 0 8 2

11

Bow Thruster -

Loaded

10 10 10 0 20 4 25 5 1 1 0 1 1 0 0 1 0 0 0 8 2

12

Conveyor -

Unloaded

10 10 10 7 10 3�5 30 5 1 0 1 0 1 1 1 1 0 1 0 2 10

13 Conveyor - Loaded 10 10 10 7 20 5�5 30 5 1 0 1 0 1 1 1 0 0 1 0 2 10

14 Crusher 40 10 10 0 30 3�5 60 5 1 0 1 0 1 0 0 0 0 0 0 8 2

15 Fan - Low Inertia 30 10 15 0 10 3�5 30 5 1 0 1 0 1 0 1 0 0 0 0 8 2

16 Fan - High Inertia 40 10 10 0 30 3�5 60 5 1 0 1 0 1 0 0 0 0 0 0 8 2

17 Feeder - screw 20 10 10 0 10 3�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

18 Grinder 40 10 10 0 20 3�5 40 5 1 0 1 0 1 0 0 0 0 0 0 8 2

19 Hammer mill 40 10 10 0 20 3�5 40 5 1 0 1 0 1 0 0 0 0 0 0 8 2

20 Lathe machines 10 10 15 0 10 3�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

21 Mills - flour Etc 40 10 10 0 20 3�5 40 5 1 0 1 0 1 0 0 0 0 0 0 8 2

22

Mixer - Unloaded

10 10 10 0 10 3�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

23 Mixer - Loaded 10 10 10 0 20 4 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

24 Moulding Machine 10 10 10 0 10 4�5 25 5 1 0 1 0 1 0 0 0 0 0 1 8 2

25 Pelletisers 40 10 10 0 20 5�5 25 5 1 0 1 0 1 0 0 0 0 0 0 8 2

26

Plastic and textile

machines

10 10 10 0 10 4�5 25 5 1 0 1 0 1 0 0 1 0 0 1 8 2

27 Press, flywheel 40 10 10 0 20 3�5 40 5 1 0 1 0 1 0 0 1 0 0 1 8 2

28

Pump -

Submersible

Centrifugal

10 10 10 60 10 3�5 25 5 1 0 0 0 1 1 1 1 0 1 0 2 25

Loading...

Loading...