2-10

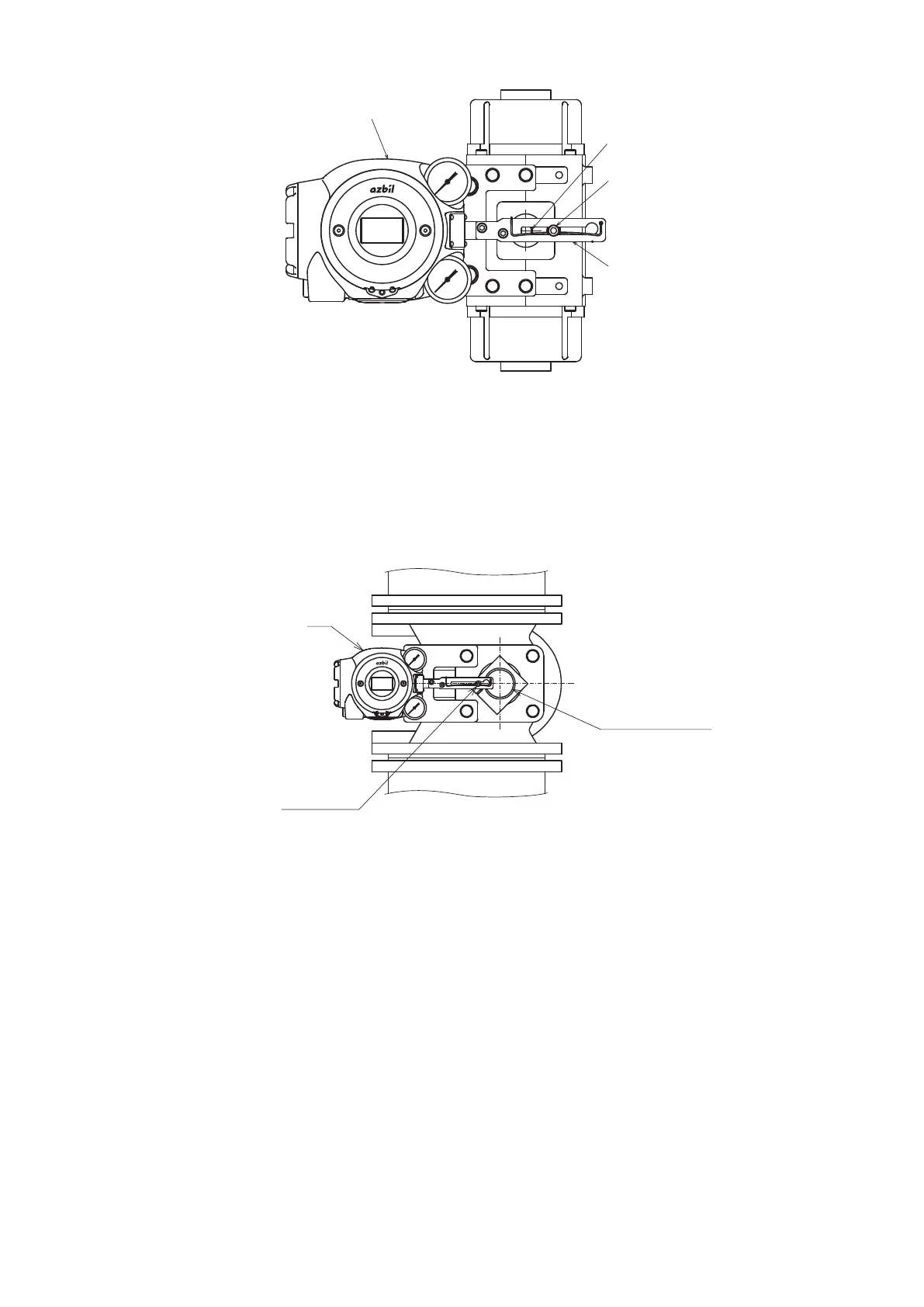

Feedback lever

Feedback pin

AVP

Figure 2-9 Connection of the Rotary Cylinder to the Feedback Pin and Feedback

Lever

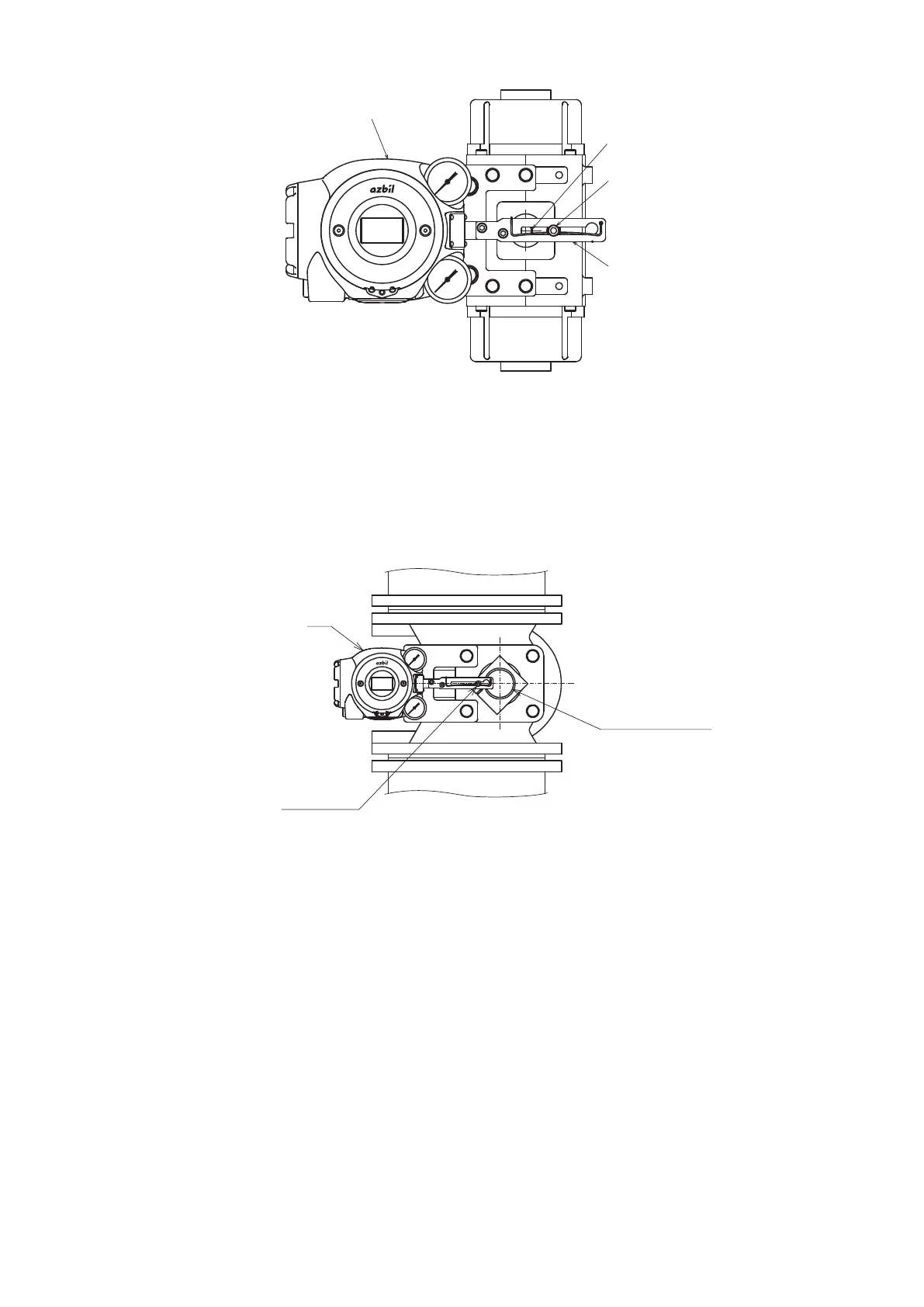

- When the rotary cylinder is large and the lever is assembled so that the feedback pin

is positioned between the 700 Series and the shaft of the rotary cylinder as shown

in the figure below, select Rotary (sub)/90° (for 90°) or Rotary (sub)/other (for angles

other than 90°) as the Actuator Type according to the rotation angle.

Feedback pin

AVP

Shaft of rotary cylinder

Figure 2-10 Feedback Pin and Feedback Lever Connection for Rotary Cylinder (Large

Cylinder)

5) Maintenance space behind the device

The device has a nozzle flapper mechanism in the back of the main unit. When cleaning

the flapper, you must remove the pilot relay cover secured to the back with three screws.

Design the clamp and feedback mechanism to ensure maintenance space for cleaning.

Loading...

Loading...