The event is turned ON when any change in PV corresponding to increase/decrease in MV

(Manipulated variable) is not observed. This event is used to detect any fault at the operation

end.

● Setting items

• Main setting: Change in PV from the point that the MV reaches the high limit (100%) or low

limit (0%).

• Sub-setting: Range of absolute value of deviation (PV-SP) allowing the event to turn OFF.

• ON delay time: Diagnosis time

• OFF delay time: A period of time from power ON allowing the event to turn OFF.

● Operation specifications

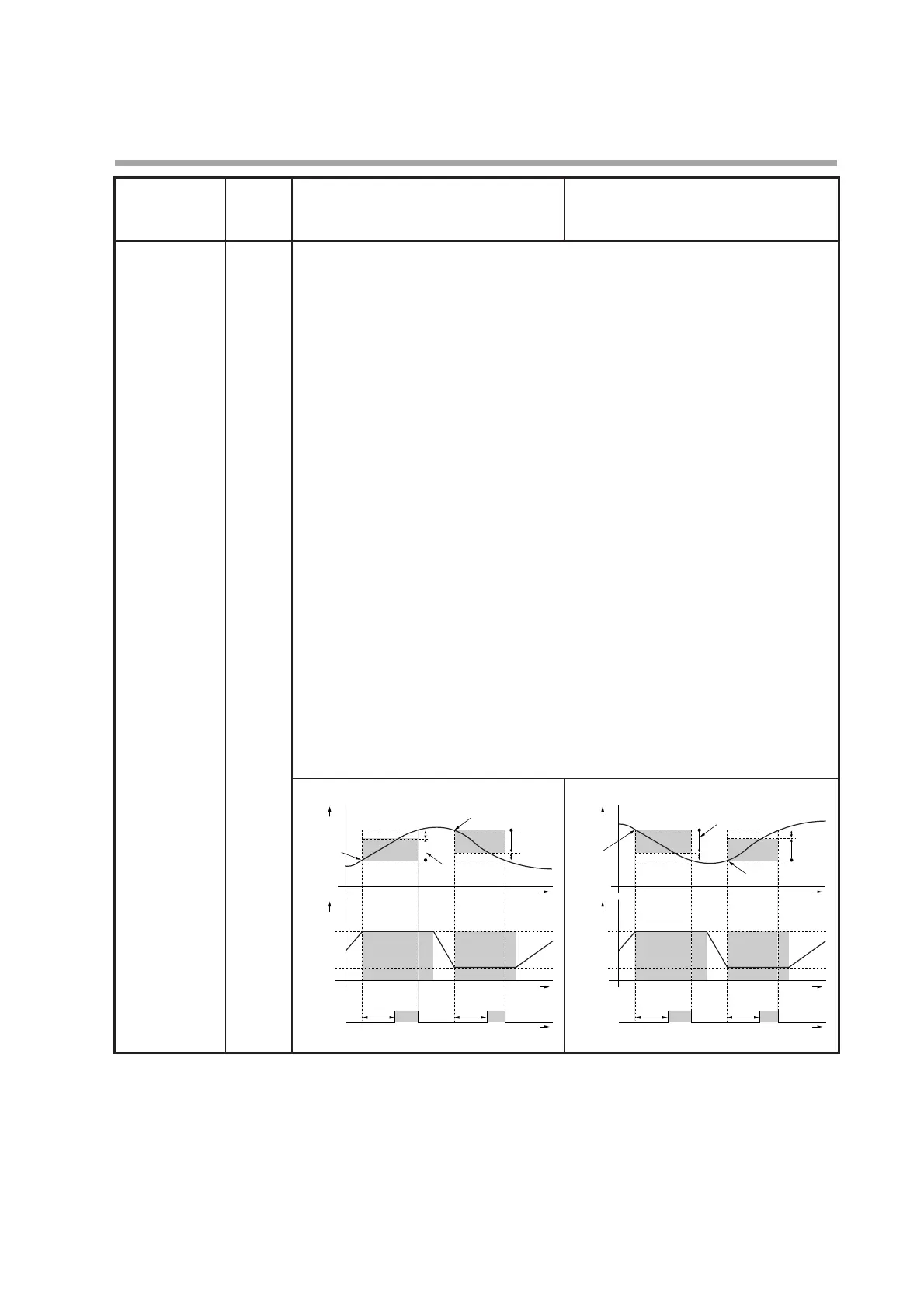

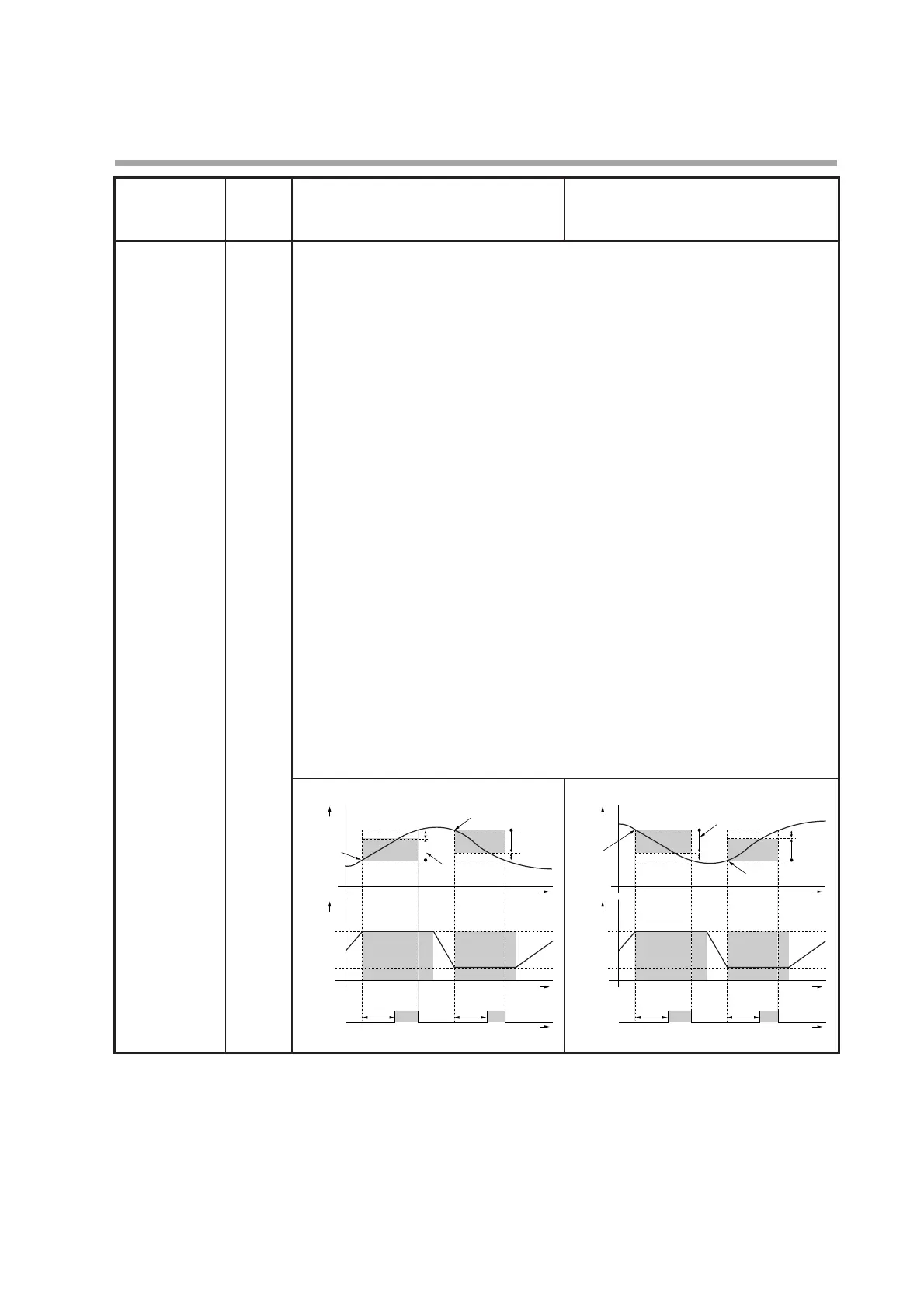

• The direct action is used for the heat control. The event is turned ON when the increase in

PV becomes smaller than the main setting after the diagnosis time (ON delay time) has

elapsed after the MV had reached the high limit or when the decrease in PV becomes

smaller than the main setting after the diagnosis time (ON delay time) has elapsed after the

MV had reached the low limit.

• The reverse action is used for the cool control. The event is turned ON when the decrease

in PV becomes smaller than the main setting after the diagnosis time (ON delay time) has

elapsed after the MV had reached the high limit or when the increase in PV becomes

smaller than the main setting after the diagnosis time (ON delay time) has elapsed after the

MV had reached the low limit.

• The event is turned OFF regardless of other conditions when the absolute value of the

deviation (PV-SP) becomes less than the sub-setting.

• The event is turned OFF regardless of other conditions when a period of time after starting

of operation after the power has been turned ON becomes less than the OFF delay time.

However, the event is turned OFF when the absolute value of the deviation is the (sub-

setting - hysteresis) value or less after the absolute value of the deviation has become the

sub-setting or more.

● CAUTION

When setting the ON delay and OFF delay, it is necessary to put in " High function

configuration".

The default settings of the ON delay and OFF delay before shipment are 0.0s.

Heat control Cool control

Loading...

Loading...