0024-9551 Revision 1

47

PCA

®

400 User Manual

IMPORTANT: When connecting the sensor assembly, it is important that the tubing

is free of crimps which could obstruct the ow of sample gases. (See Figure 5-5 for

proper sensor cap orientation.)

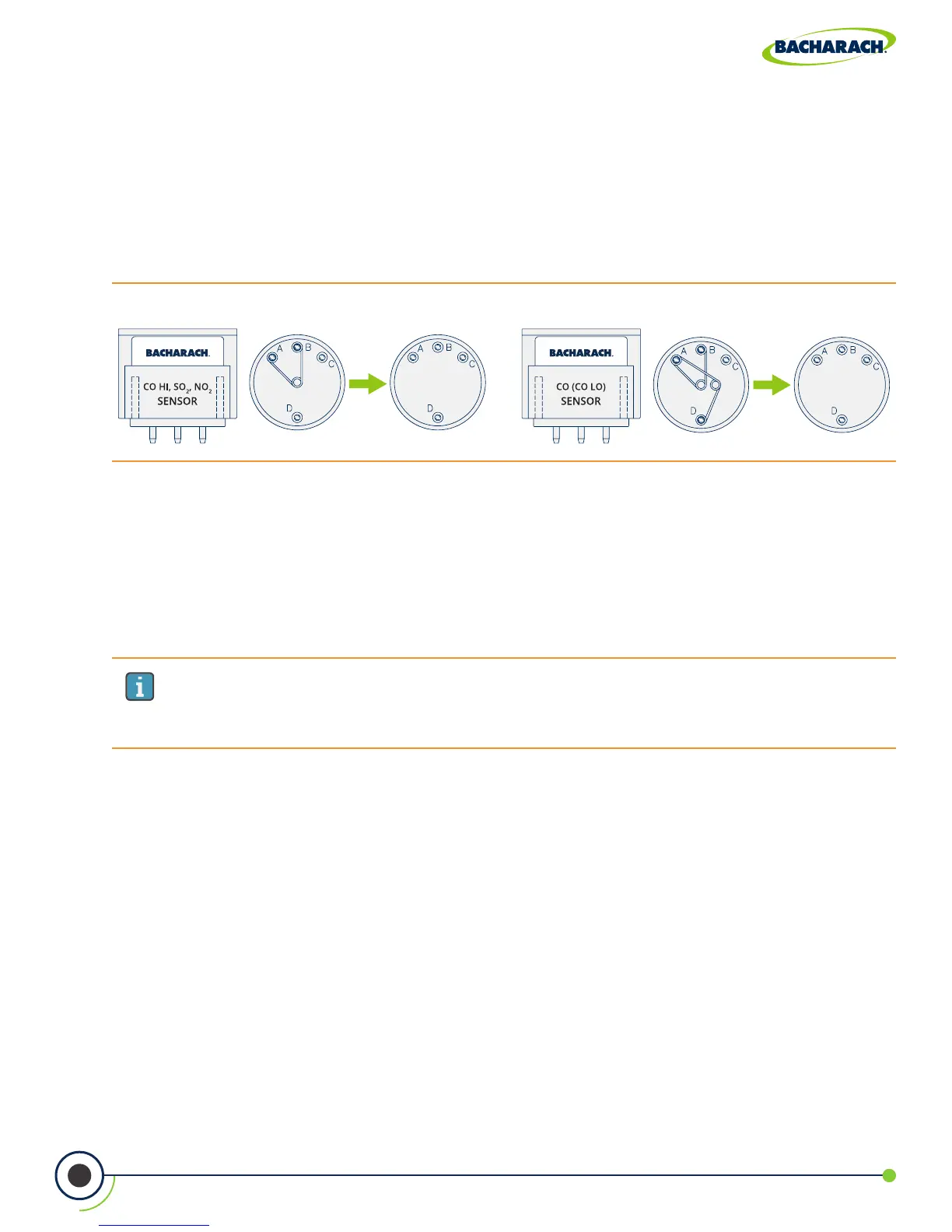

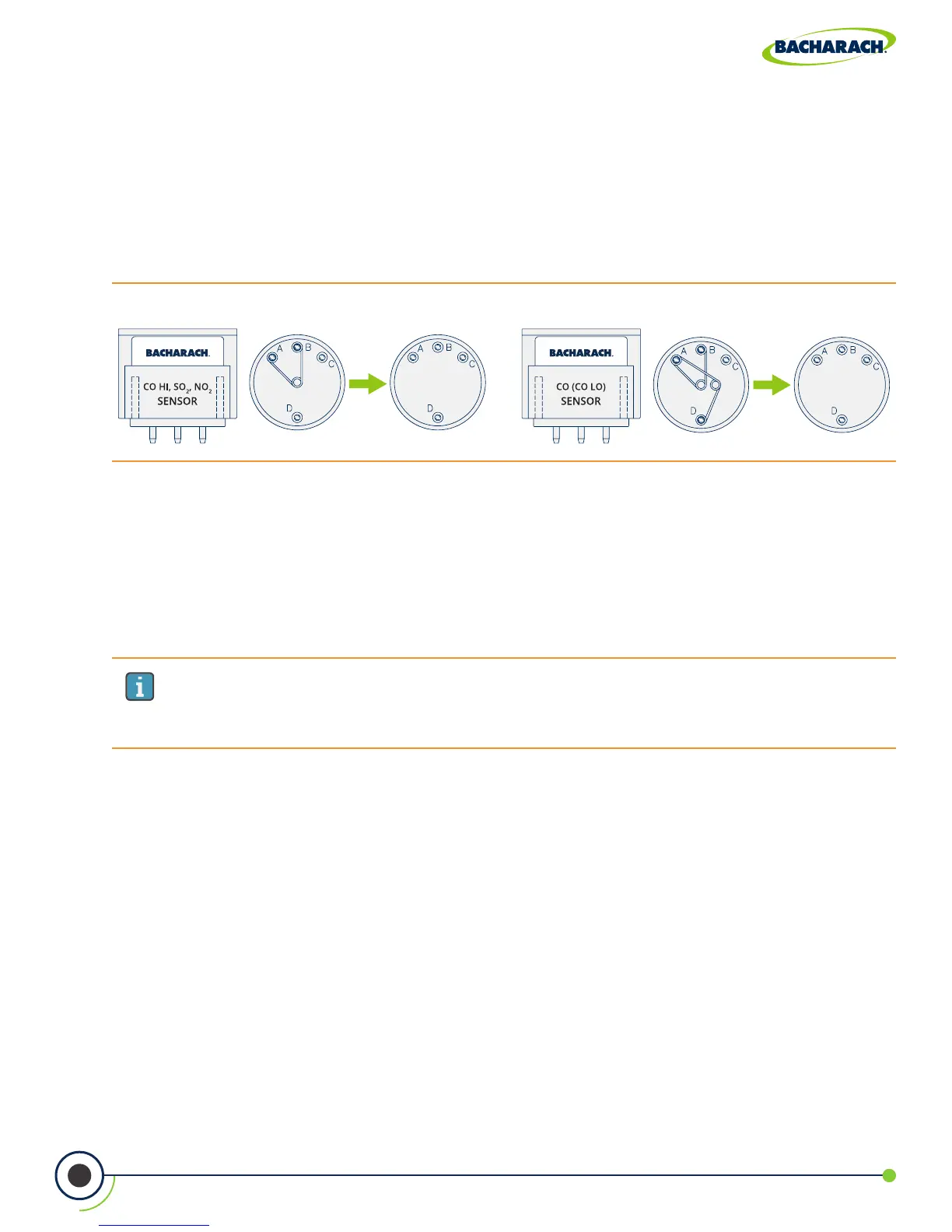

Fig. 5-4: Discard Shorting Springs

8. Reinstall the Analyzer’s Rear Cover

Using a Phillips-head screwdriver, return Battery & Component Doors to the rear of

the analyzer.

9. Allow Replacement Sensor to Stabilize

Allow the sensor which was just installed time to stabilize in the circuit before continuing

with this procedure. Stabilization time for all sensors (except for the NO sensor) is about

1-hour. The NO sensor baseline technically requires several days to stabilize, but should

be suciently stabilized for use in approximately 4-hours.

10. Turn ON the Analyzer

Press the Power Key and ensure that no sensor errors occur during the 60-second

warm-up.

6. Attach Sensor Cap Assembly

Attach the cap assembly to the replacement sensor by inserting the sensor into the gas

cup and twisting in a clockwise fashion.

7. Connect Replacement Sensor

Firmly press the sensor into the vacant position on the board and reconnect the sample

tubing to the gas cup.

4. Remove Sensor Cap Assembly

While holding the base of the sensor, rmly twist the gas cup in a counterclockwise fashion

and pull straight up to remove.

5. Remove Shorting Springs from Replacement Sensor

Remove the replacement sensor from its plastic canister / packaging. Note that the CO

LOW

,

CO

HIGH

, SO

2

and NO

2

sensors have a shorting spring installed between two of their pins.

Remove and discard this spring before installing the sensor

Loading...

Loading...