9424200996 65-7

BE1-11m Inverse Overcurrent (51) Test

applying only a single-phase input. For example, to determine the pickup current value required

for a 1 A BE1-11m with a pickup setting of 0.1, it would require 0.1 times 3 or 0.3 amperes of

input current.

Step 6: Slowly increase the A-phase current until OUT2 closes and record the pickup. Verify that there

is a 51-1-Neg SEQ target on the front-panel display. Slowly decrease the applied current until

OUT2 opens and record the dropout.

Step 7: Repeat step 6 for the middle and high range pickup settings for your sensing input type. Record

the results.

Step 8: (Optional.) Repeat steps 1 through 7 for settings group 1, 2, and 3.

Step 9: (Optional.) Repeat steps 1 through 8 for 51-2, 51-3, 51-4, and 51-5.

Step 10: (Optional.) Repeat steps 1 through 9 with CT Circuit 2 as the source for protection systems

equipped with two sets of CTs. In step 5, replace D1 with F1, D2 with F2, etc.

Timing Verification (I2 Mode)

Step 1: Use BESTCOMSPlus to open the Protection, Current, Inverse Overcurrent (51-1) screen and

send the test settings in Table 65-11 to the BE1-11m for settings group 0.

Table 65-11. Timing Test Settings (I2 Mode)

0.5 A (5 A sensing), 0.1 A (1 A sensing)

Step 2: Prepare to monitor the 51-1 timings. Timing accuracy is verified by measuring the elapsed time

between a sensing current change and OUT1 closing.

Step 3: Connect a current source to BE1-11m terminals D1 and D2 (A-phase).

Step 4: Using the values listed in Table 65-12, apply the appropriate current values, and measure the

time between the application of current and the closure of OUT1. Record the results.

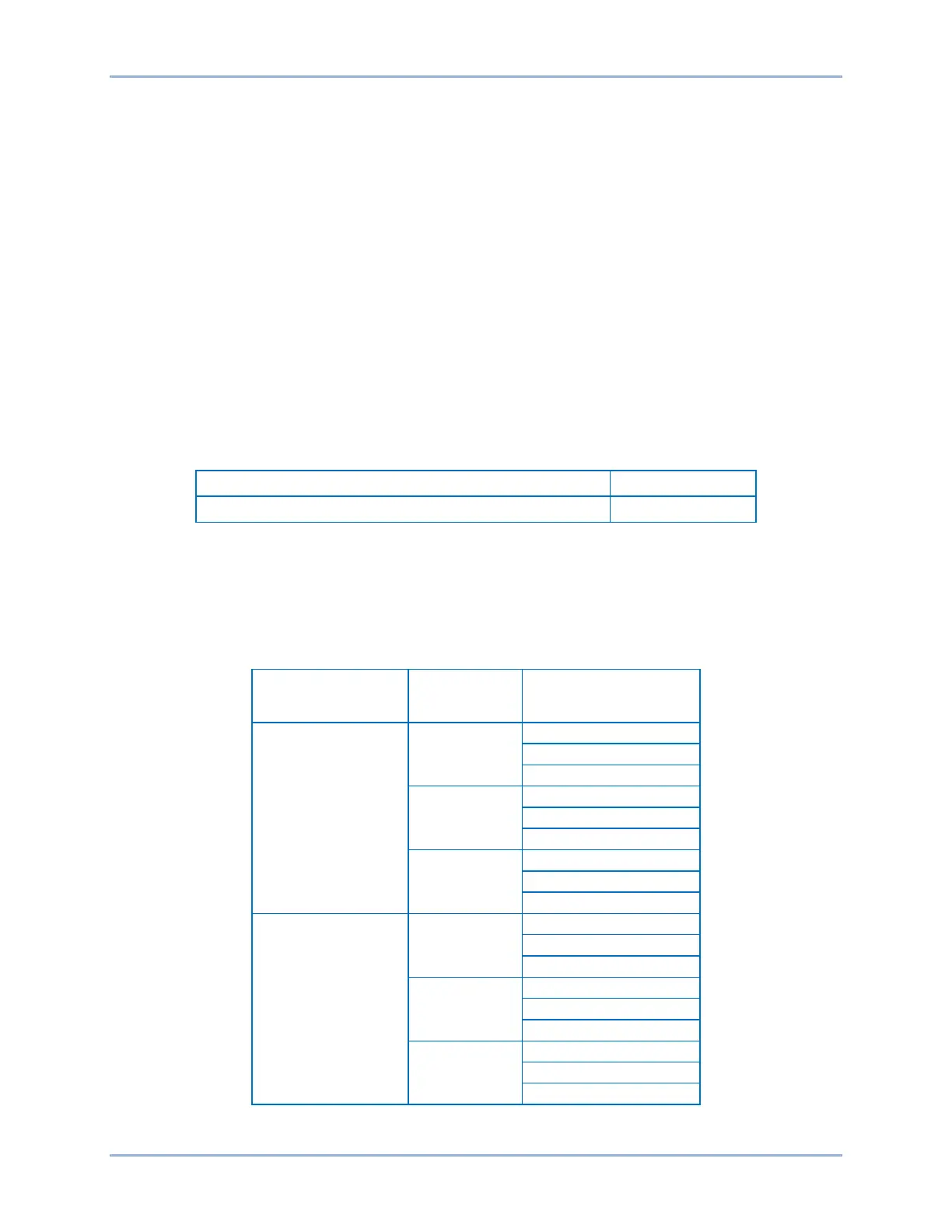

Table 65-12. Timing Test Settings (I2 Mode)

Sensing Type Time Dial Applied Current

5 A

0.5

5.0

9.9

1 A

0.5

5.0

9.9

Step 5: Repeat step 4 for all of the current and time dial settings for your current sensing type.

Loading...

Loading...