© BEKA 201 !6 All rights reserved

BAL2185_PICO_with_PICOtroniX1_PICOtronic_0816_EN

...a product of BEKA

Theconnection ofthe control unitis done viathe leftHirschman plug atthe control unithousing ofthepump (fig.28).

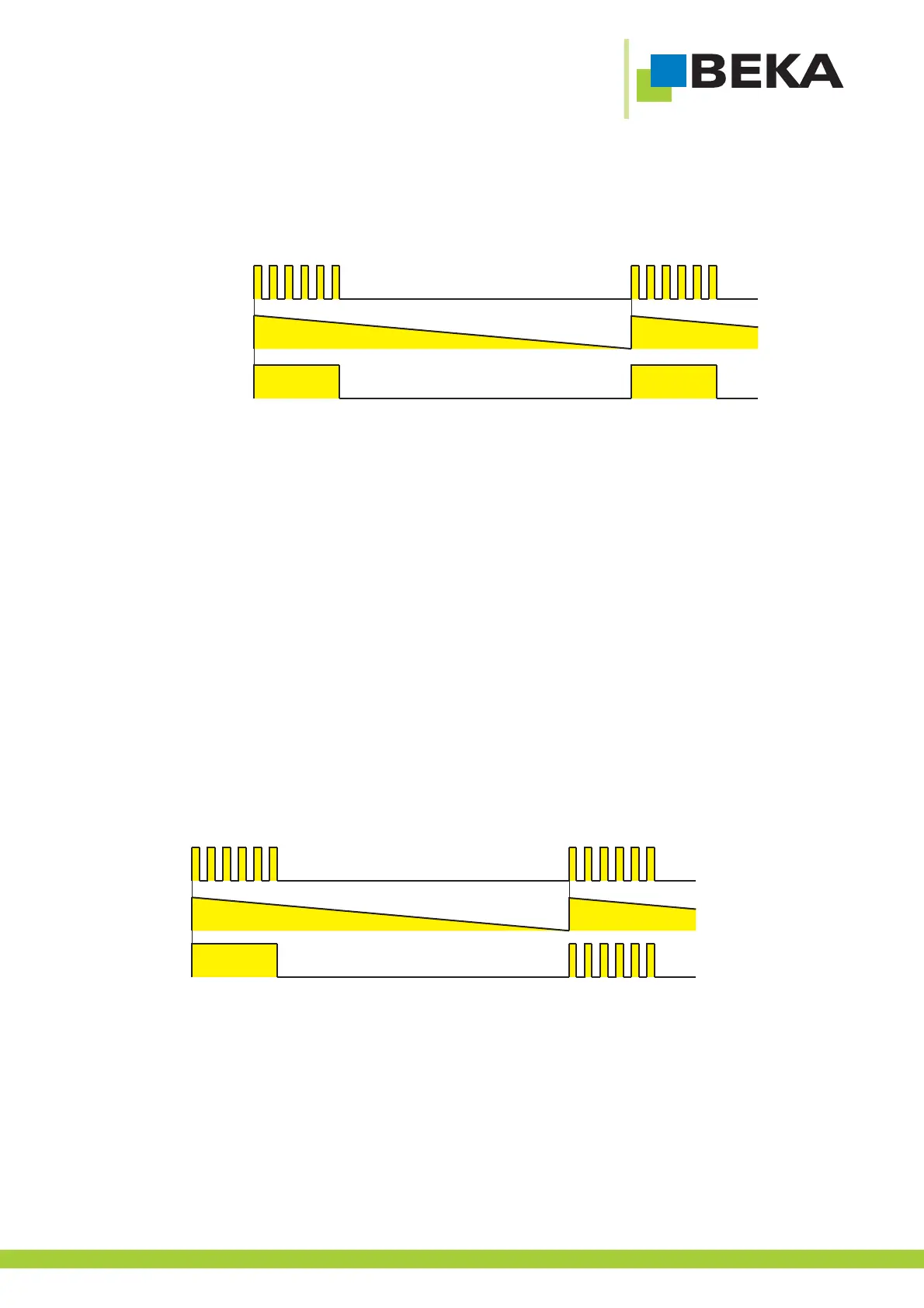

Fig.34:

The change of pulse range and monitoring time is done by means of the BEKADiSys software (current version available

onBEKAwebsite).

Setting ranges:

1to 16pulses (16 notchesà 1 pulse)

17to 32pulses (16 notchesà 1 pulse)

33to 48pulses (16 notchesà 1 pulse)

Thepulse settingis done bymeans of theswitch inthe control unitwindow (see 9.1.3change parameter)

9.3.3 Operating mode lubrication speed-dependent

The speed-dependent control unit of a lubrication system counts the number of revolutions of a pump motor. For this

purpose a sensor is installed that sends a signal at each motor revolution. If the signal is overdue for longer than the set

monitoring time (standard 30 sec.) the control unit sends a malfunction signal (see 12.3 signal of integrated control unit

PICO-tronic).

Erroris resetwith the intermediatelubrication button afterthe problemhas been solved.

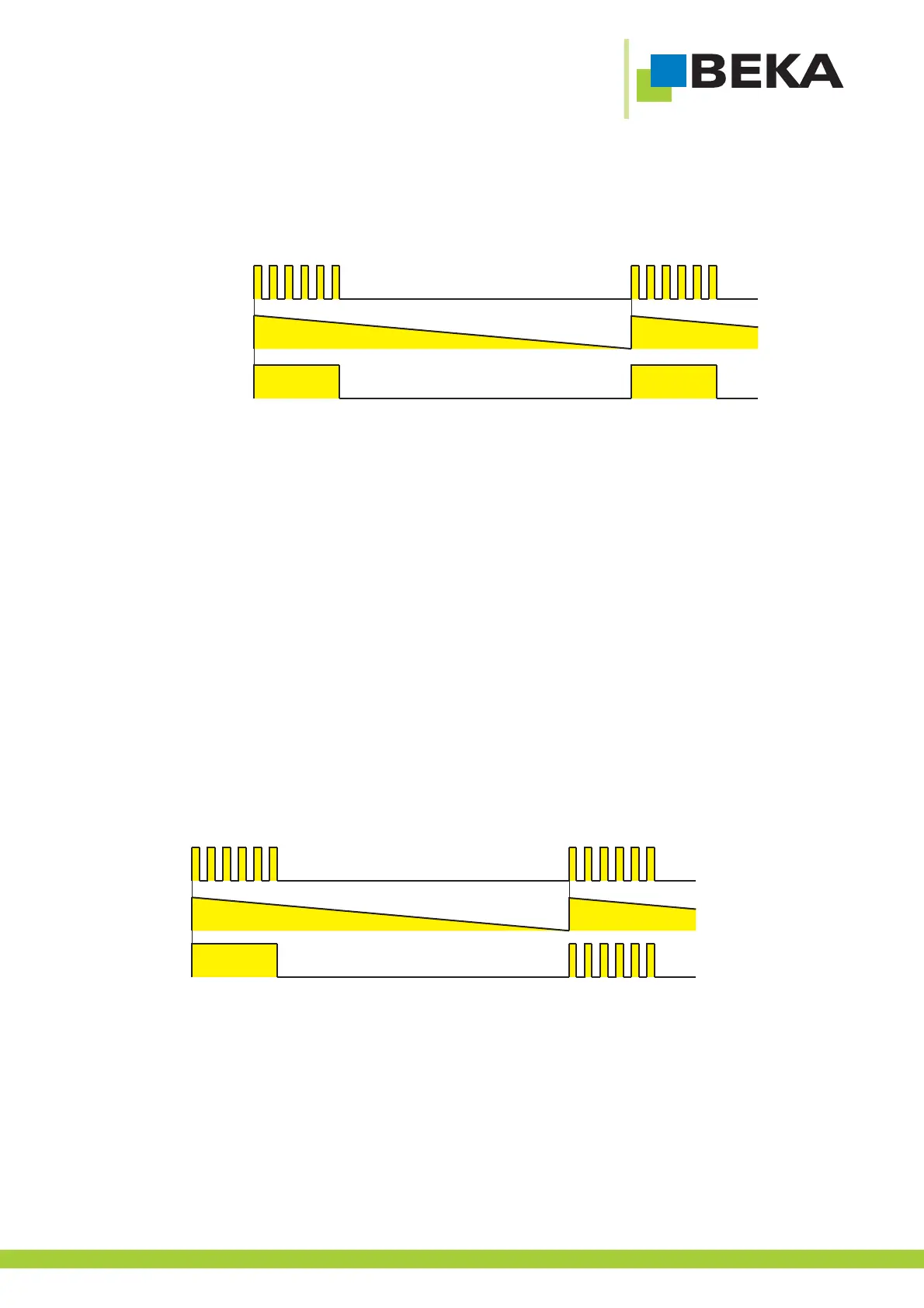

Fig.35:

The setting range for the number of motor revolutions is done by means of the BEKA DiSys software (current version

availableon BEKAwebsite).

Setting ranges:

10to 16revolutions (16 notchesà 1 revolution)

10to 160revolutions (16 notchesà 10 revolutions)

170to 320revolutions (16 notchesà 10 revolutions)

The number of motor revolution setting is done by means of the switch in the control unit window (see 9.1.3 change

parameter)

distributor pulses

cycle duration

lubrication/

pump

revolutions

cycle duration

lubrication /

pump

Loading...

Loading...