04/03 347 LB 444

30

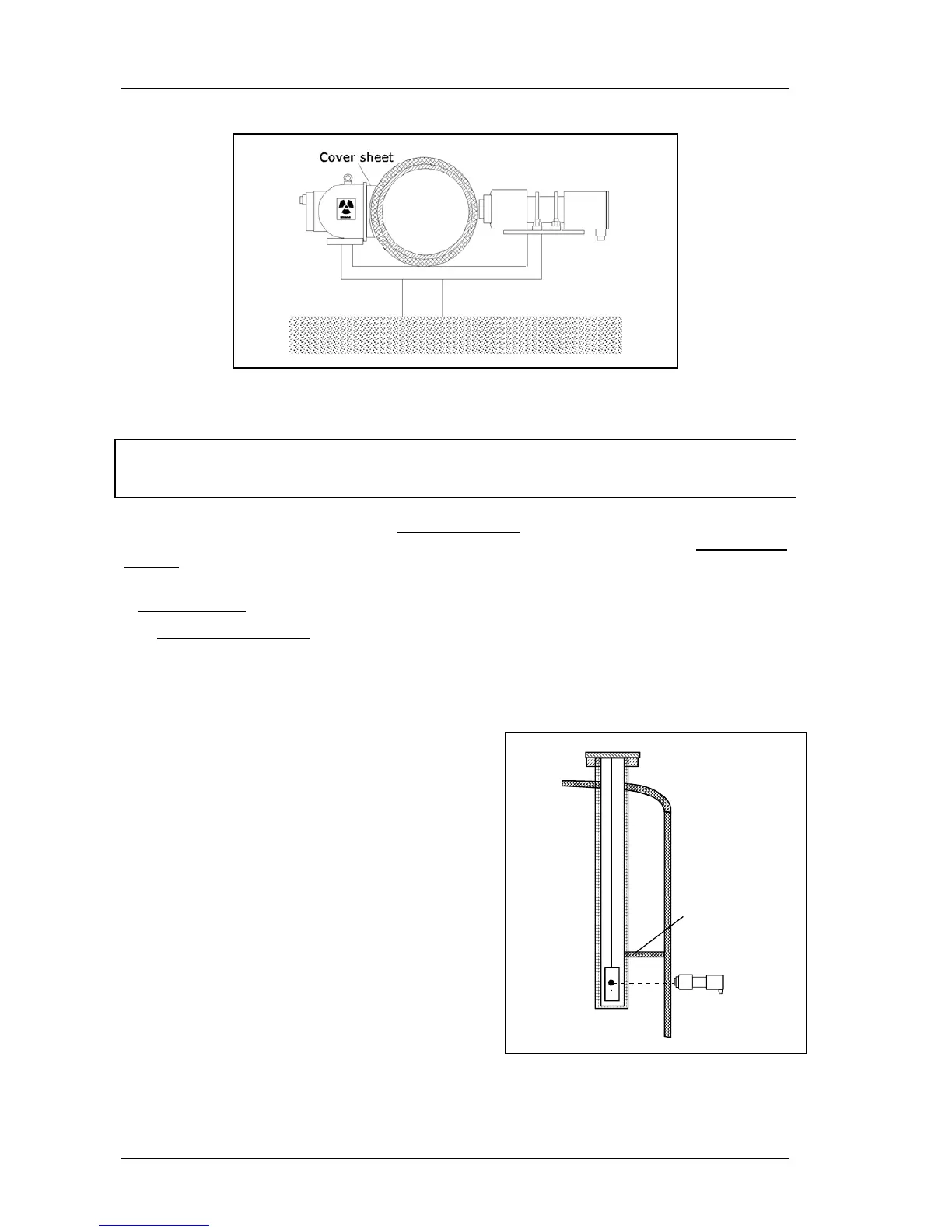

Figure 14: External installation of shielding and detector

To comply with the Radiation Protection Regulation, areas with dose rates

> 3000 µSv/h (300 mrem/h) – so-called restricted areas – must be secured to

rule out that personnel is exposed to radiation (see local regulations!)

The pipeline must not be subject to heavy vibrations

as this could damage the detector.

If this cannot be avoided, the shielding container and the detector must be installed ex-

ternally (see Figure 14).

Since the calibration of the measurement requires that samples of the product be taken,

a sampling point

has to be provided near the installation.

The product temperature

for temperature compensation must be measured directly next

to the density measurement.

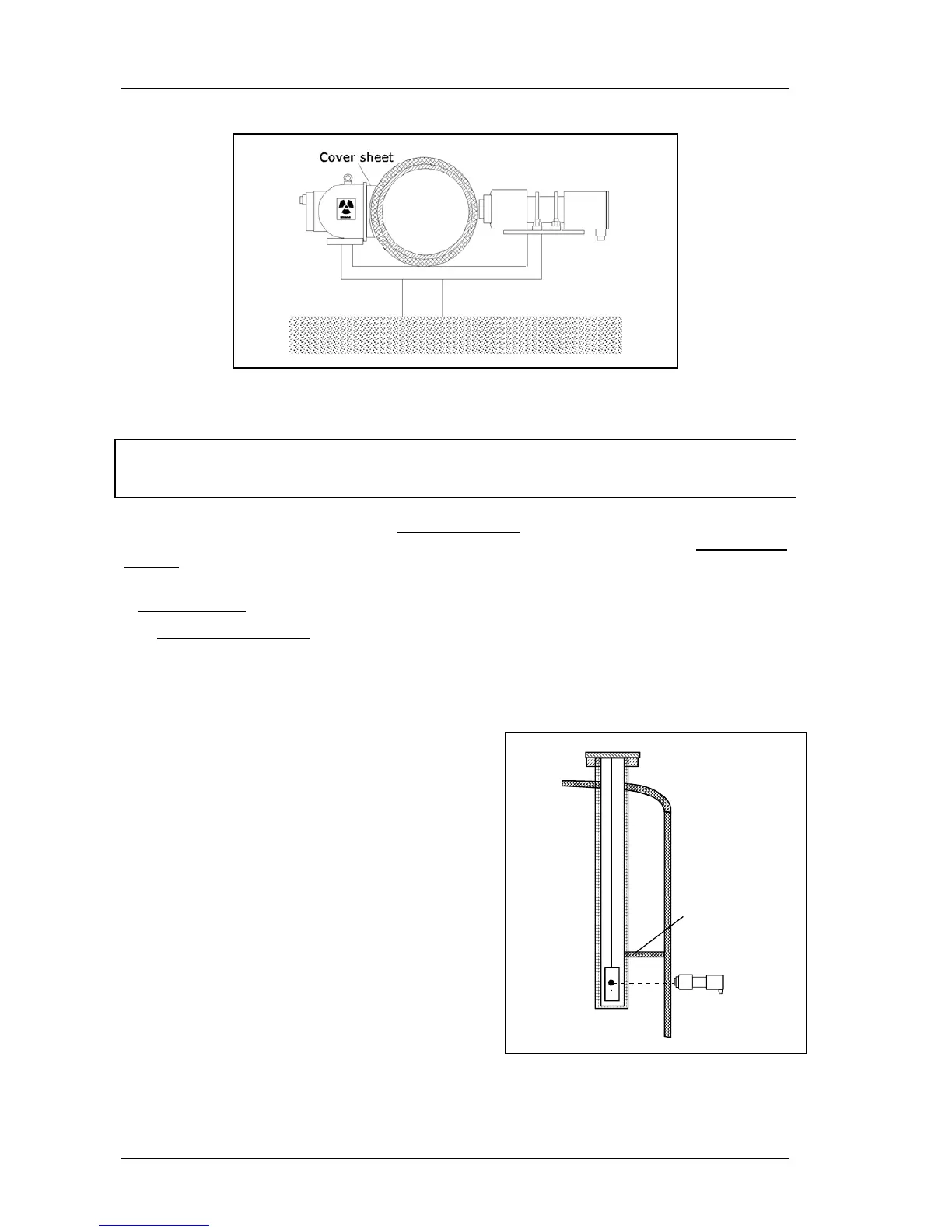

5.2.2 Installation in a Container

If density measurements are carried out in a

container, the source is installed in a special

lead shielding in a protection tube inside the

container. Special care must be taken that the

measuring path is not changed by bending the

protection pipe, as this would lead to signifi-

cant measurement errors. An additional brace

may be required for very long protection tu-

bes. The material of the protection pipe must

be sufficiently resistant to the product being

measured.

Installation has to be done such that the ra-

diation path lies diagonally to the flow direc-

tion. With horizontal flow the radiation exit

channel should point toward the bottom to

prevent deposit formation in the path of radia-

tion.

Brace

Figure 15: Installation in a container

Loading...

Loading...