04/03 347 LB 444

82

10.5 Detector

10.5.1 Checking the Crystal-Multiplier Assembly

A plateau that is too small or too steep indicates faults in the crystal-multiplier assembly.

Please proceed as follows to perform a visual inspection of crystal and multiplier:

Switch off the scintillation counter before opening the instrument.

Do not perform the check in bright daylight, as this may damage the photo

cathode of the photo multiplier.

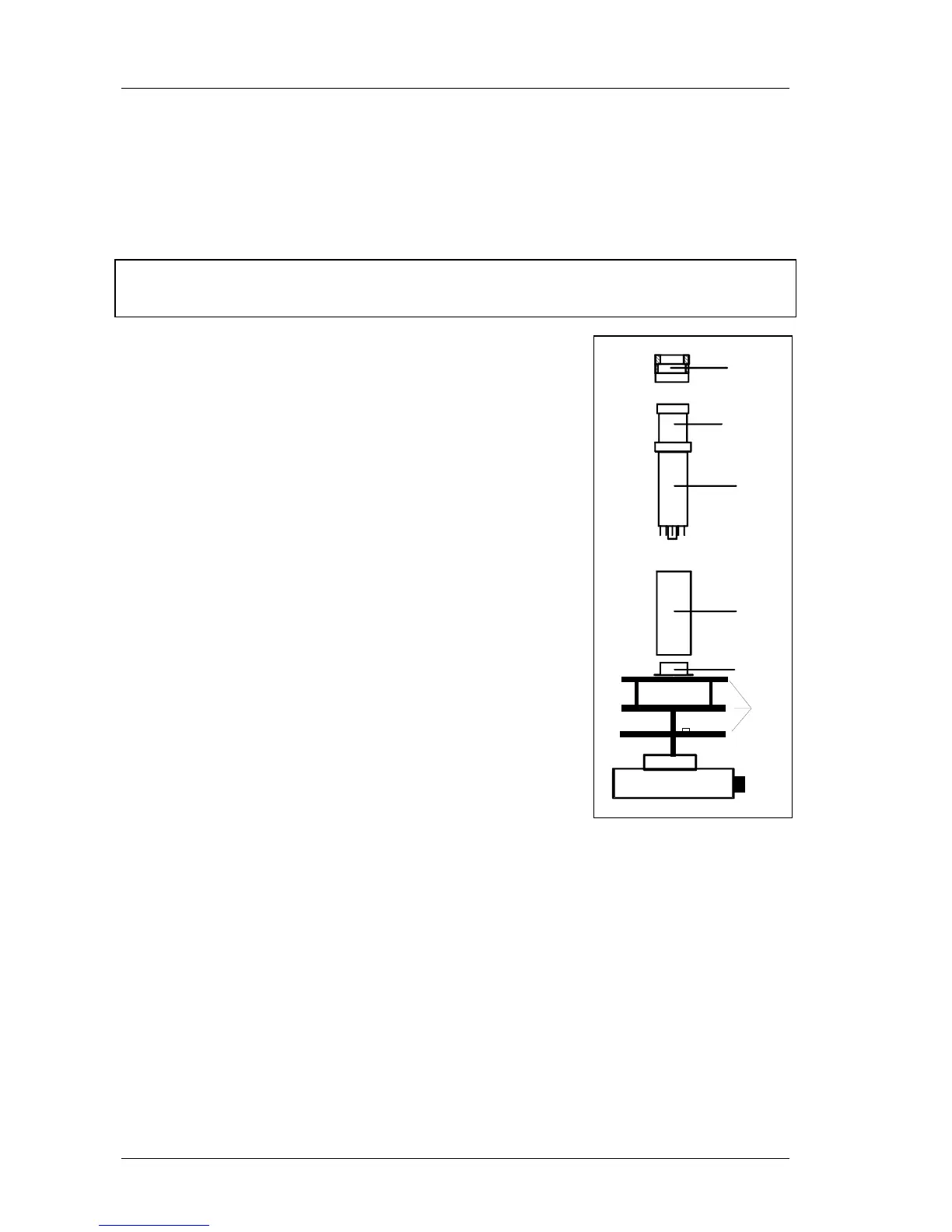

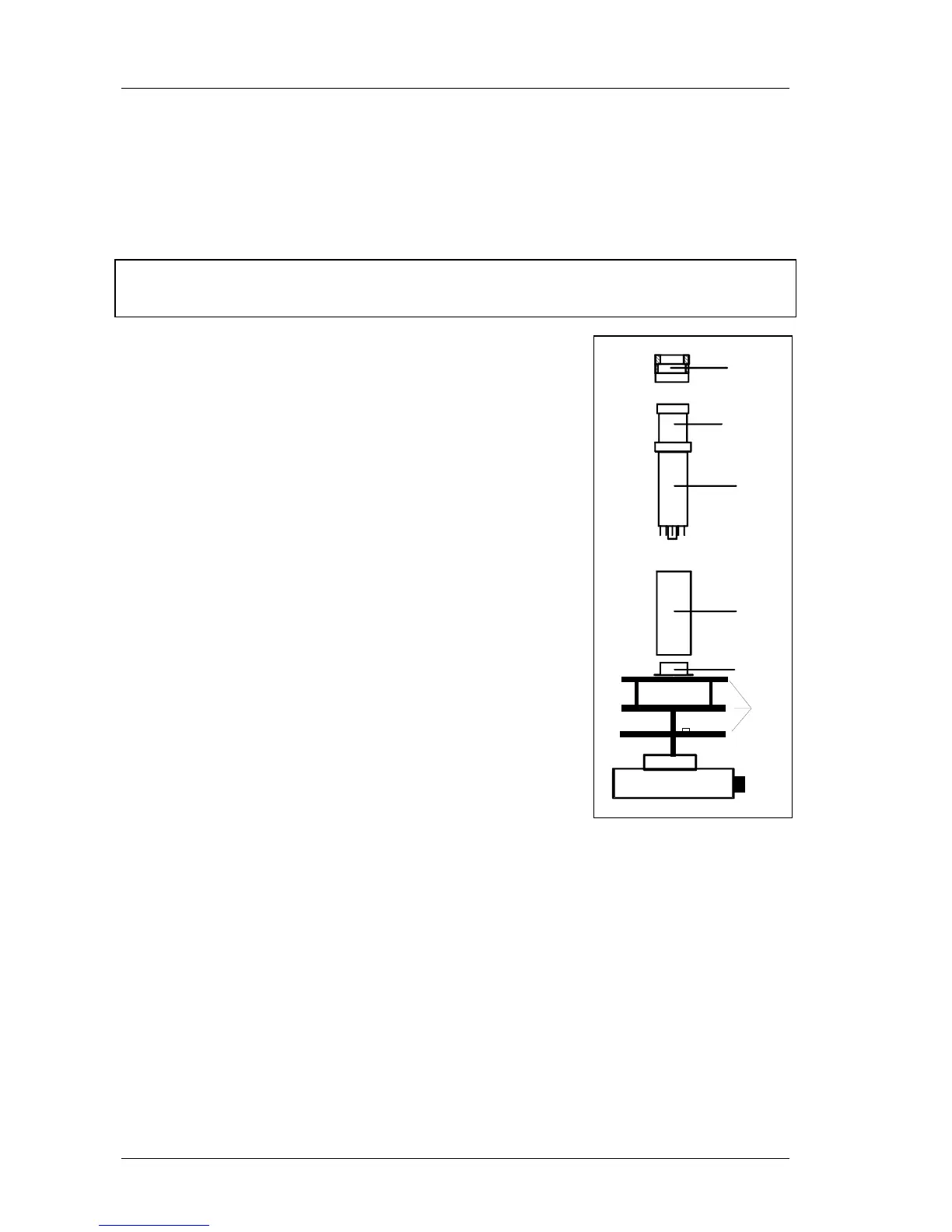

Open the scintillation counter by removing the cover of the

connection box first and then the screws of the base. The

entire electronics (1) with the crystal/multiplier combina-

tion can then be detached from the housing.

Remove photo multiplier combination from base (2) and

unscrew ring nut (3) on front panel. The multiplier (4) in-

cluding crystal (5) can now be detached from the Mu-metal

shielding (6).

A thin layer of silicone oil between crystal and multiplier

ensures optical coupling; silicone oil is rather viscous, par-

ticularly at low temperatures. Carefully detach the crystal

from the multiplier window by gently sliding the crystal

sideways. Do not wipe off the silicone oil!

Check:

The crystal must be perfectly clear inside and not show

any dull areas. Its typical color is white. A yellowish to

brownish coloring is a sign of thermal overload and indi-

cates that the crystal has to be replaced. The surrounding

white reflecting layer must not be damaged. You can only

check the photo multiplier for glass breakage or other me-

chanical damage. Other faults cannot be identified by visual

checks alone. However, if the crystal does not show any

faults, a bad plateau indicates that the photo multiplier is

faulty.

(a)

(b)

(c)

3

5

4

6

2

1

The multiplier window is coated with a vapor-deposited

layer acting as photocathode. This layer gives the window a

brownish tint similar to smoked glass. If this layer is no

longer present or if it is stained, then the photocathode has

been destroyed (e.g. by overheating, glass breakage, or

incident light), and the multiplier must be replaced. Faults

caused by damage to the dynode systems (e.g. by exces-

sive vibration) cannot be identified by appearance. If in

doubt, replace the multiplier.

The glass pane at the mating face to the photo multiplier

must not show any cracks.

Figure 32: Assembly of

scintillation counter

1 = Electronics part with

(a) CPU, b) HV, (c)

voltage divider

2 = Base

3 = Ring nut

4 = Photomultiplier

5 = Crystal

6 = Mu-metal shielding

Before re-assembly, apply a drop of clean silicon oil between crystal and multiplier and

distribute it evenly by gentle rubbing to ensure sound optical connection between both

Loading...

Loading...