ENGINE

EAS20472

ENGINE

EAS20520

ADJUSTING THE VALVE CLEARANCE

The following procedure applies to all of the

valves.

IP

• Valve clearance adjustment should be made

on a cold engine, at room temperature.

• When the valve clearance is to be measured or

adjusted, the piston must be at top dead center

(TDC) on the compression stroke.

1. Remove fuel tank

2. Disconnect:

• Spark plug cap

3. Remove:

4. Spark plug

5. Cylinder head c

over

6. Cylinder head cover gasket

4. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

5. Measure:

• Valve clearance

Out of specification → Adjust.

▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

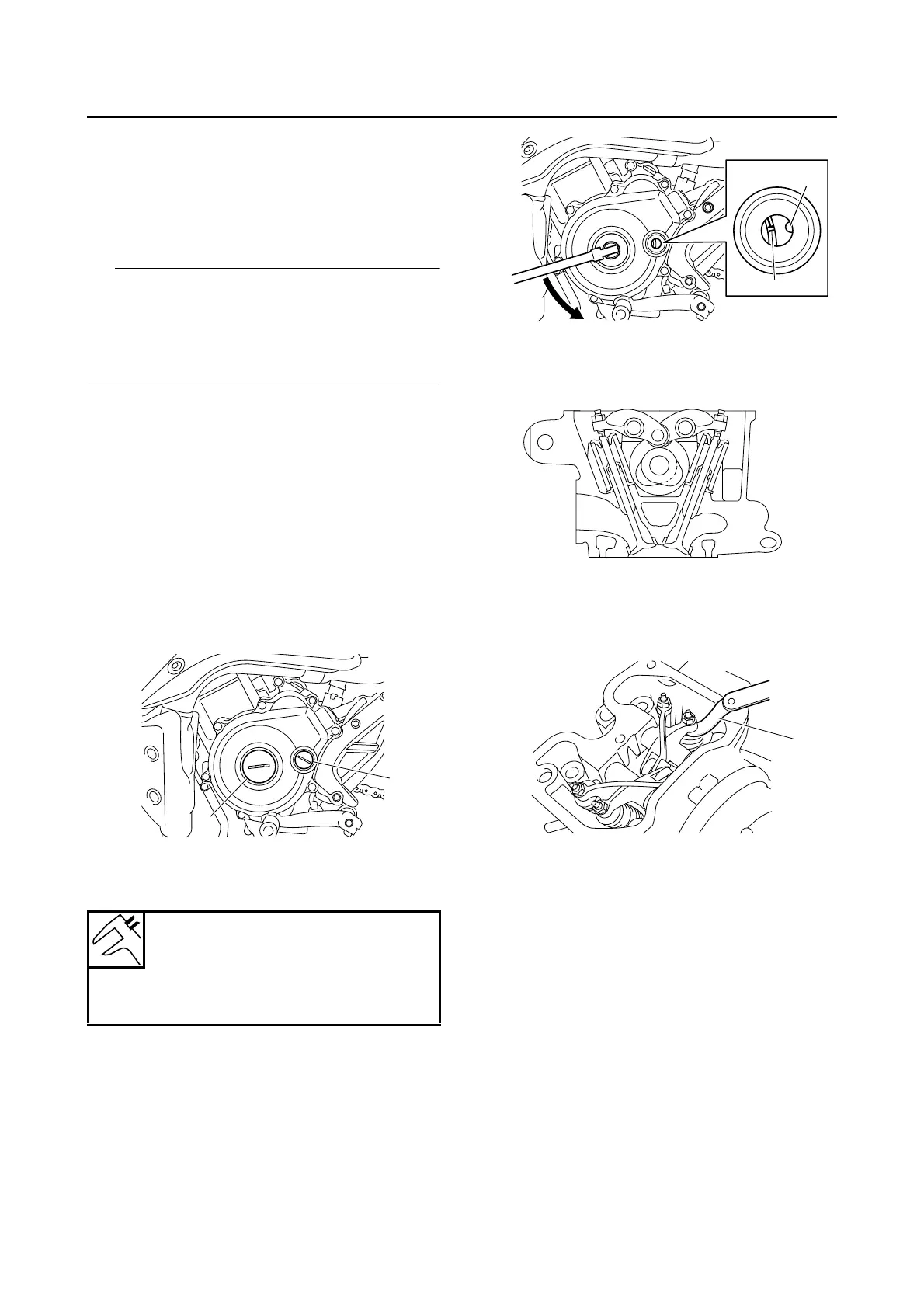

a. Turn the crankshaft counterclockwise.

b. Align the TDC mark “a” on the generator rotor

with the stationary pointer “b” on the genera-

tor cover.

c. Check that the cam lobes are positioned as

shown in the illustration.

d.

Measure the valve clearance with a thickness

gauge “1”.

Out of specification → Adjust.

▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲▲▲

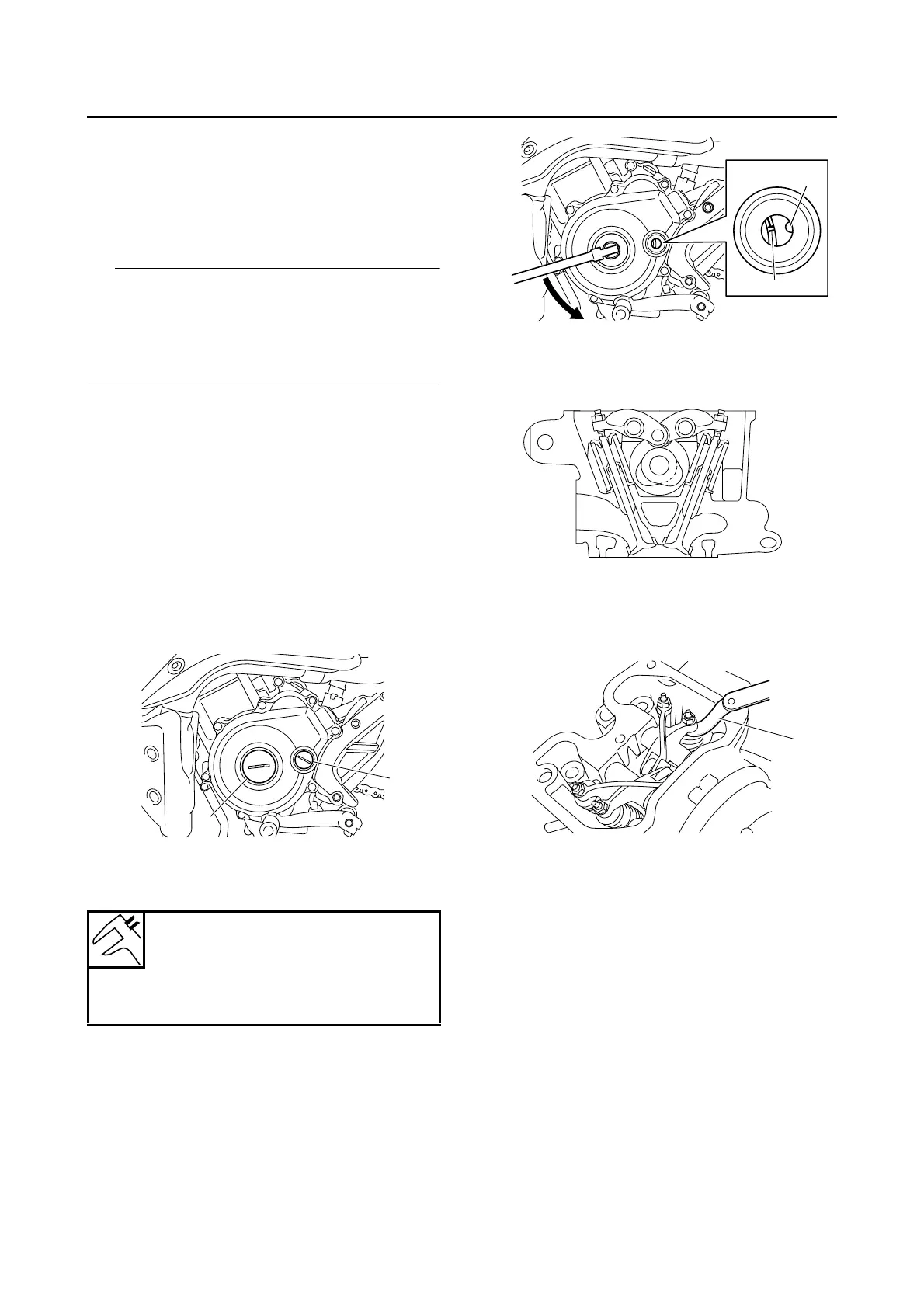

6. Adjust:

• Valve clearance

▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

a. Loosen the locknut “1”.

b. Insert a thickness gauge “2” between the end

of the adjusting screw and the valve tip.

Valve clearance (cold)

Intake

0.10–0.14 mm (0.0039–0.0055 in)

Exhaust

0.20–0.24 mm (0.0079–0.0094 in)

2

1

b

a

1

Loading...

Loading...