OIL PUMP

EAS24960

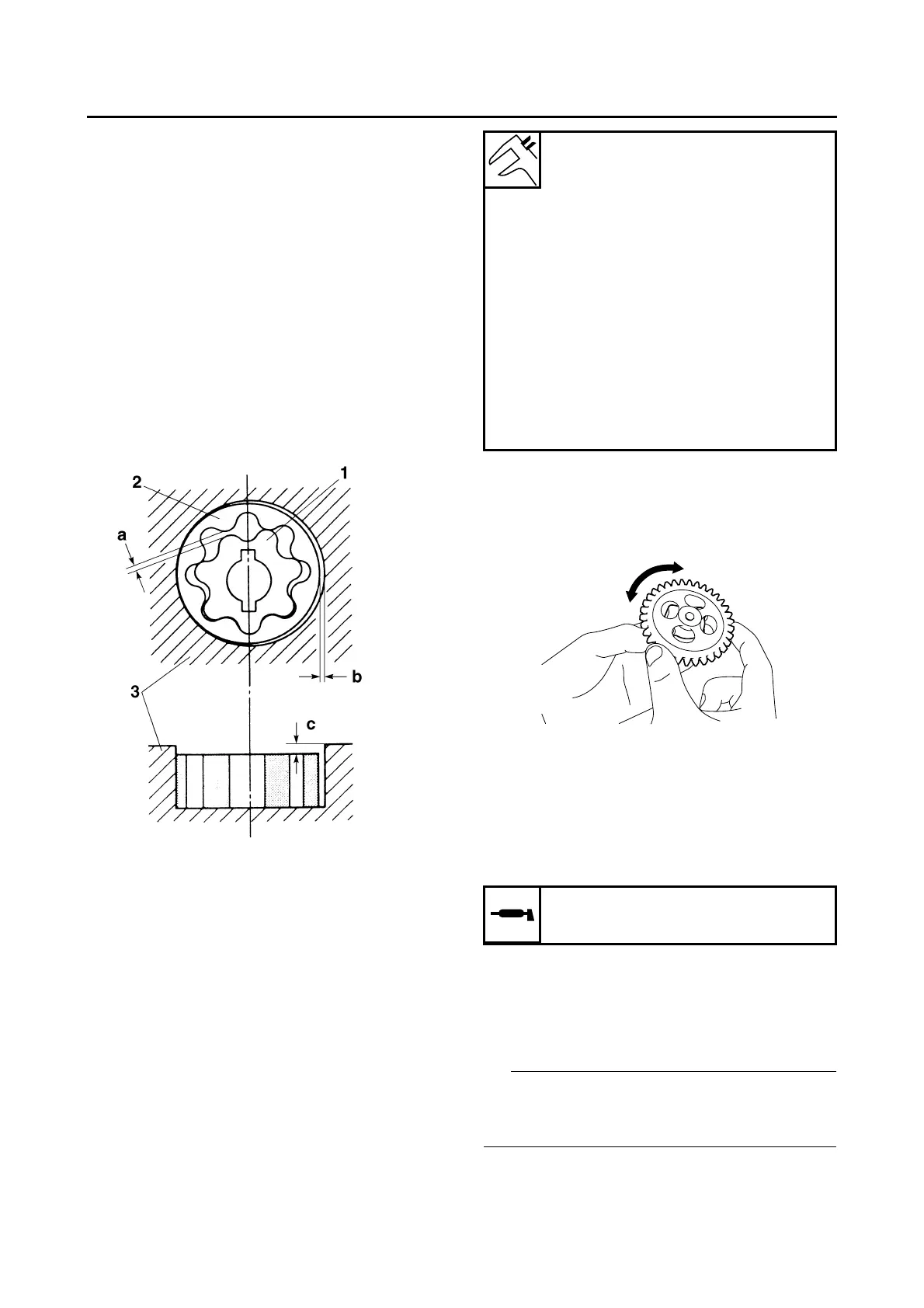

CHECKING THE OIL PUMP

1. Check:

• Oil pump drive gear

• Oil pump driven gear

• Oil pump housing

• Oil pump housing cover

Cracks/damage/wear → Replace the defec-

tive part(s).

2. Measure:

• Inner-rotor-to-outer-rotor-tip clearance “a”

• Outer-rotor-to-oil-pump-housing clearance

“b”

• Oil-pump-housing-to-inner-rotor-and-outer-

rotor clearance “c”

Out of specification → Replace the oil pump.

3. Check:

• Oil pump operation

Rough movement → Repeat steps (1) and

(2) or replace the defective part(s).

EAS25000

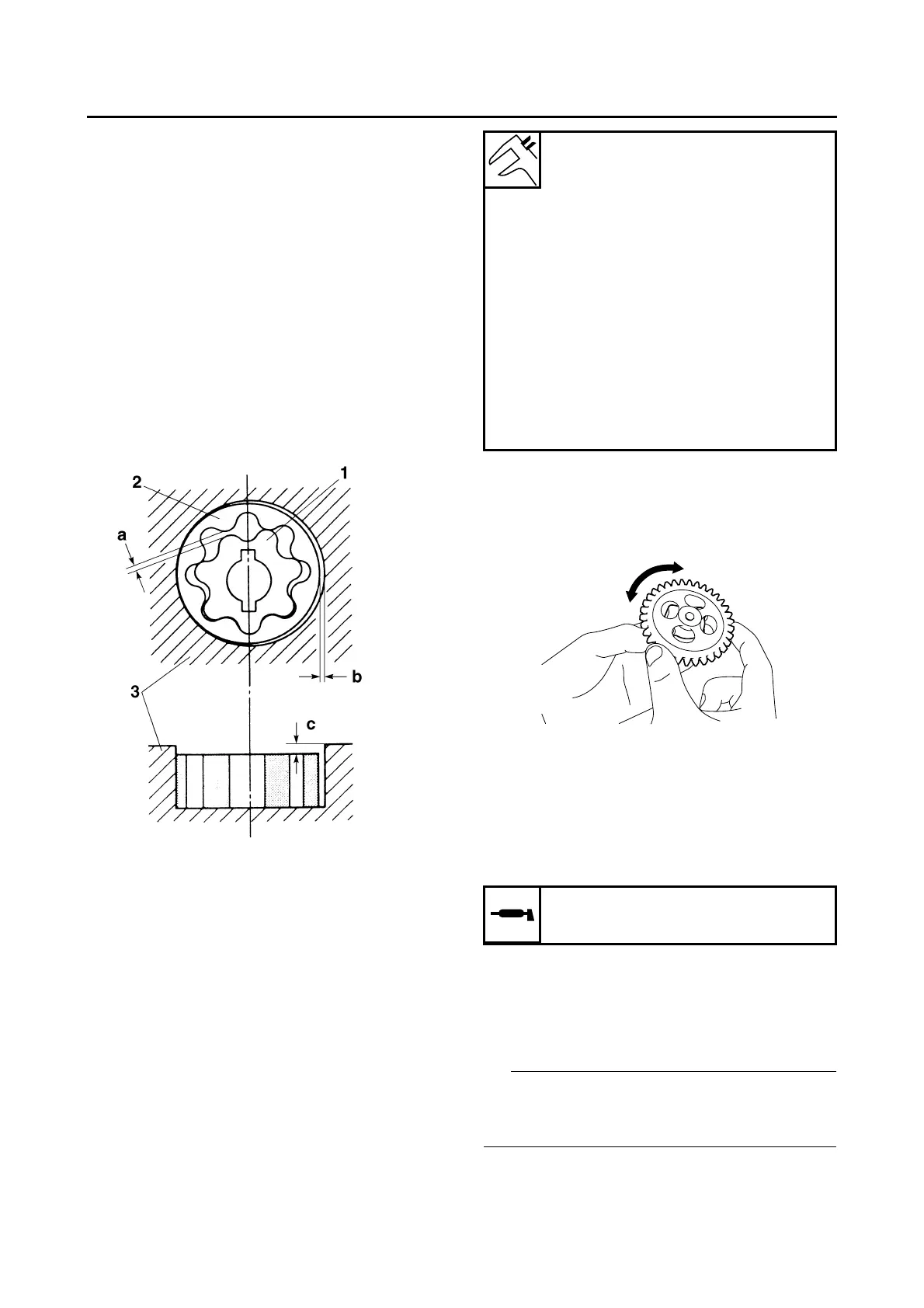

ASSEMBLING THE OIL PUMP

1. Lubricate:

• Oil pump inner rotor

• Oil pump outer rotor

• Oil pump driven gear

(with the recommended lubricant)

2. Install:

• Oil pump outer rotor

• Oil pump inner rotor “1”

• Oil pump driven gear

• Pin “2”

IP

When installing the inner rotor, align the pin “2”

in the oil pump shaft with the groove “a” in the in-

ner rotor.

1. Inner rotor

2. Outer rotor

3. Oil pump housing

Inner-rotor-to-outer-rotor-tip

clearance

Less than 0.150 mm (0.0059 in)

Limit

0.23 mm (0.0091 in)

Outer-rotor-to-oil-pump-housing

clearance

0.130–0.180 mm (0.0051–0.0071

in)

Limit

0.25 mm (0.0098 in)

Oil-pump-housing-to-inner-and-

outer-rotor clearance

0.06–0.11 mm (0.0024–0.0043 in)

Limit

0.18 mm (0.0071 in)

Recommended lubricant

Engine oil

Loading...

Loading...