30

100%

100%

0%

0%

BIFFI F01-2000 ELECTRIC ACTUATOR

INSTRUCTION AND OPERATING MANUAL

Default #2

Monitor relay

- main voltage failure

- lost phase

- local/off selected

- local stop pressed

- manual operation

- internal temperature alarm

- K1 contactor failure

- K2 contactor failure

- position sensor failure

- speed sensor failure

- configuration error

- HW error

- motor over-temperature

- over-torque

- jammed valve

- low lithium battery (if present)

- mid-travel alarm

Auxiliary relays

AS1: open limit; break

AS2: close limit; break

AS3: position >90%; break

AS4: position <5%; break

AS5: motor running; make

AS6: remote selected; make

AS7: warning; make

AS8: local selected

Configure output relays

• Press YES to change the monitor

relay or NO to change auxiliary relays

AS1, 2, 3, 4, 5, 6, 7, 8.

Monitor relay

• Press YES or NO to enable or disable the

following situations from the conditions

which de-energize the monitor relay: motor

over-temperature, over-torque, jammed

valve, manual override, ESD signal on,

low lithium battery (if present), local STOP

pressed, LOCAL/OFF selected.

Auxiliary relays AS1, 2, 3, 4, 5, 6, 7 and 8

• Press NO to answer prompt

“MONITOR RELAY change?”.

• Press YES to change AS1, press NO to select

the other relays.

• Press YES if the condition associated to AS1

relay is correct, press NO to scrolls the list of

conditions and press YES to set.

• Press YES or NO to either confirm or change

the type of contact when the condition

occurs (break, make). Since relay AS8 is

change-over, this option is not available.

• Press NO to pass to AS2 and then repeat the

procedure for the other relays.

• Press NO to exit.

9�1�7 Positioner

The positioning function is only available in

inching or modulating F01-2000 actuators

and allows to position the valve according to a

“position request R%” command signal.

The positioning function compares the present

actuator position % with the position request

R%, and if the difference is greater than the

dead band the actuator is driven to reach the

new requested position.

The “position request R%” signal may either be

received from the bus or the 4-20 mA analog

input. If the F01-2000 is set to receive the

position request R% from the bus, a fieldbus

interface card must be present, or a Hardware

alarm will be generated. If the F01-2000 is

set to receive the position request R% from

the 4-20 mA generator, the Ain/Aout card

must be present, or a Hardware alarm will be

generated.

The following options can be configured via

local operator interface:

- Dead band: configurable from “position

resolution%” to 25.5% of the maximum

position error. The configured value should be

great enough to avoid the hunting effect.

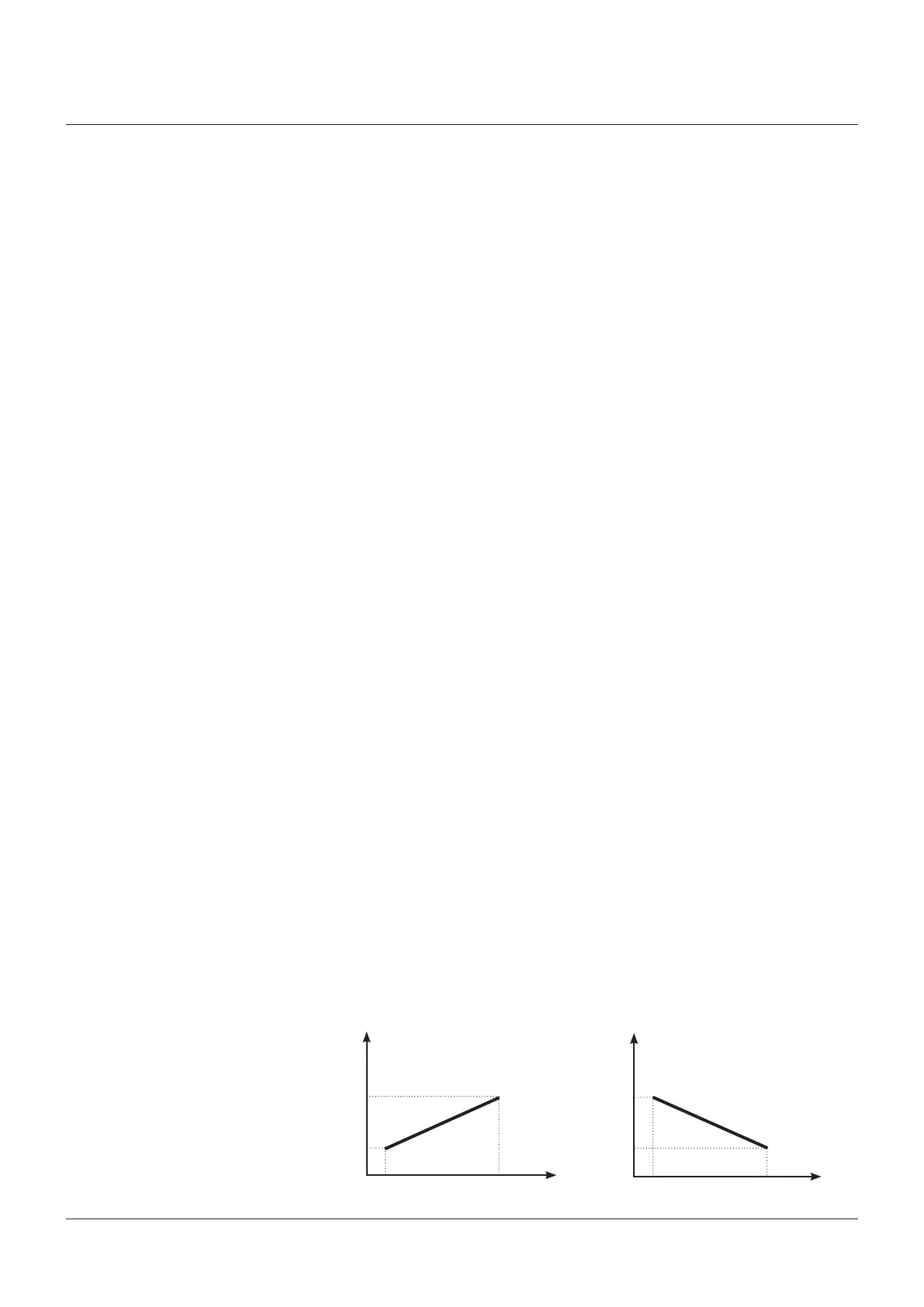

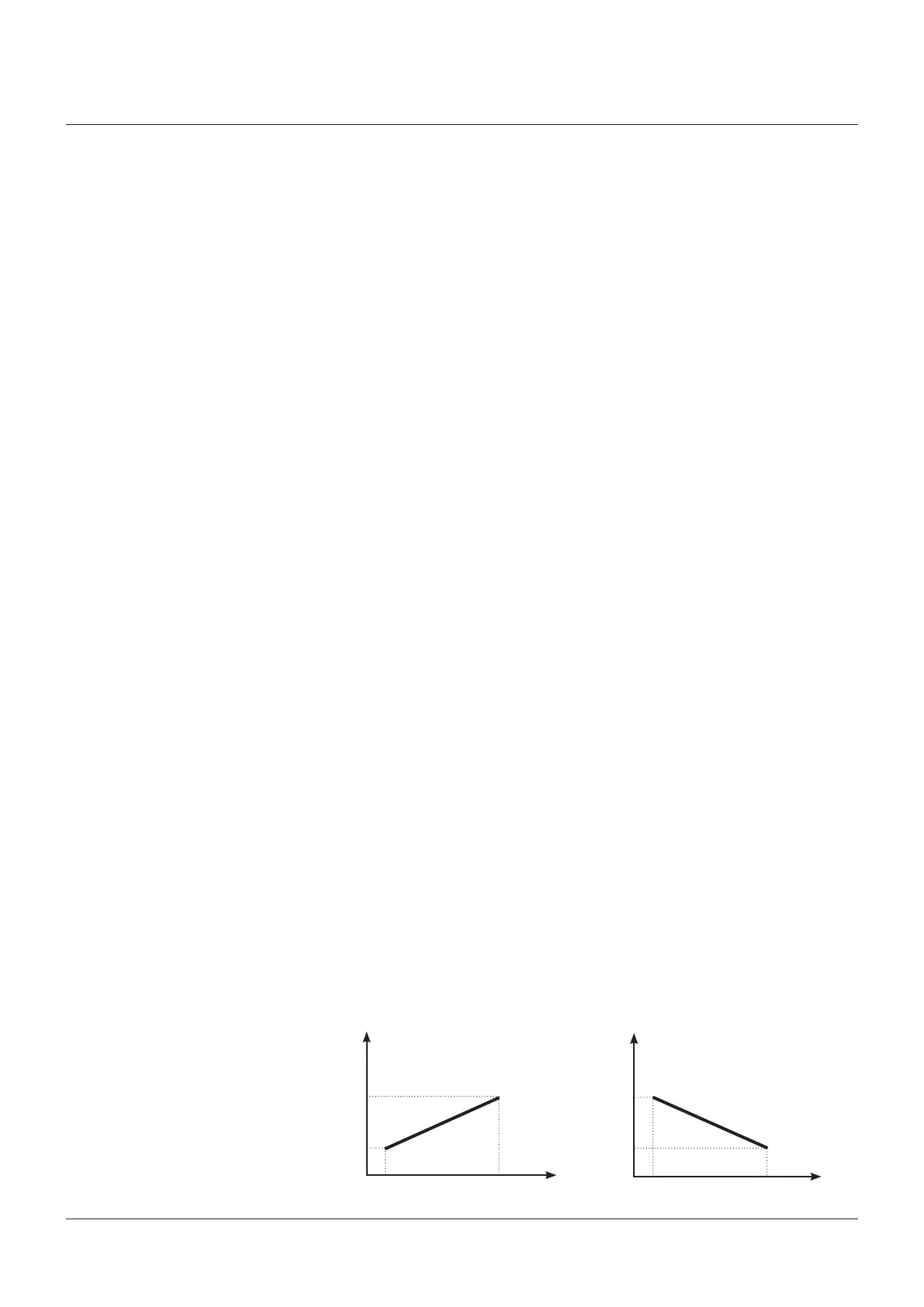

- Polarity of the 4-20 mA position request

signal: it allows to reverse the relationship

between the 4-20 mA input signal and

the “position request R%”, according to

the following diagrams. The option is not

available when the F01-2000 is set to receive

the “position request R%” from the bus.

- Motion inhibit time: it allows to adjust the

length of the delay time between two cycles

of the motor. It can be configured from

1 to 255 secs and allows to set the maximum

number of start/hour of the electrical motor.

- % MIN and % MAX, 4-20 mA input signal

range: it allows to change the relationship

between the input signal and the position

request R%. This function is useful when

a single 4-20 mA signal is used to control

the position of 2 valves (e.g.: split range

applications). The option is not available when

the F01-2000 is set to receive the “position

request R%” from the bus.

INPUT 4-20 mA

POLARITY: 4 mA = CL

Input request

20 mA

4 mA

Position %

20 mA

4 mA

INPUT 4-20 mA

POLARITY: 4 mA = OP

Input request

Position %

Default #1

Monitor relay

- main voltage failure

- lost phase

- local/off selected

- local stop pressed

- manual operation

- internal temperature alarm

- K1 contactor failure

- K2 contactor failure

- position sensor failure

- speed sensor failure

- configuration error

- HW error

- motor over-temperature

- over-torque

- jammed valve

- low lithium battery (if present)

- mid-travel alarm

Auxiliary relays

AS1: open limit; make

AS2: close limit; make

AS3: position >90%; make

AS4: position <5%; make

AS5: motor running; make

AS6: overtorque; make

AS7: ESD active; make

AS8: motor overtemperature

Loading...

Loading...