September 2019

Installation, Operation and Maintenance Manual

MAN720_IMVS2000v2_IOM Rev. 6

MAN720_IMVS2000v2_IOM Rev. 6

Section 13: Trouble Shooting

Trouble Shooting

Section 13: Trouble Shooting

WARNING

If the device is located in hazardous area a ‘’hot permit’’ must be obtained before opening the explosion

proof enclosures. Moreover, the area must be cleaned from explosive mixture since batteries and power

supply could generate electrical spark and cause explosion.

WARNING

During the opening and closing the IMVS2000v2 units, pay attention do not damage the joint surface

of the covers.

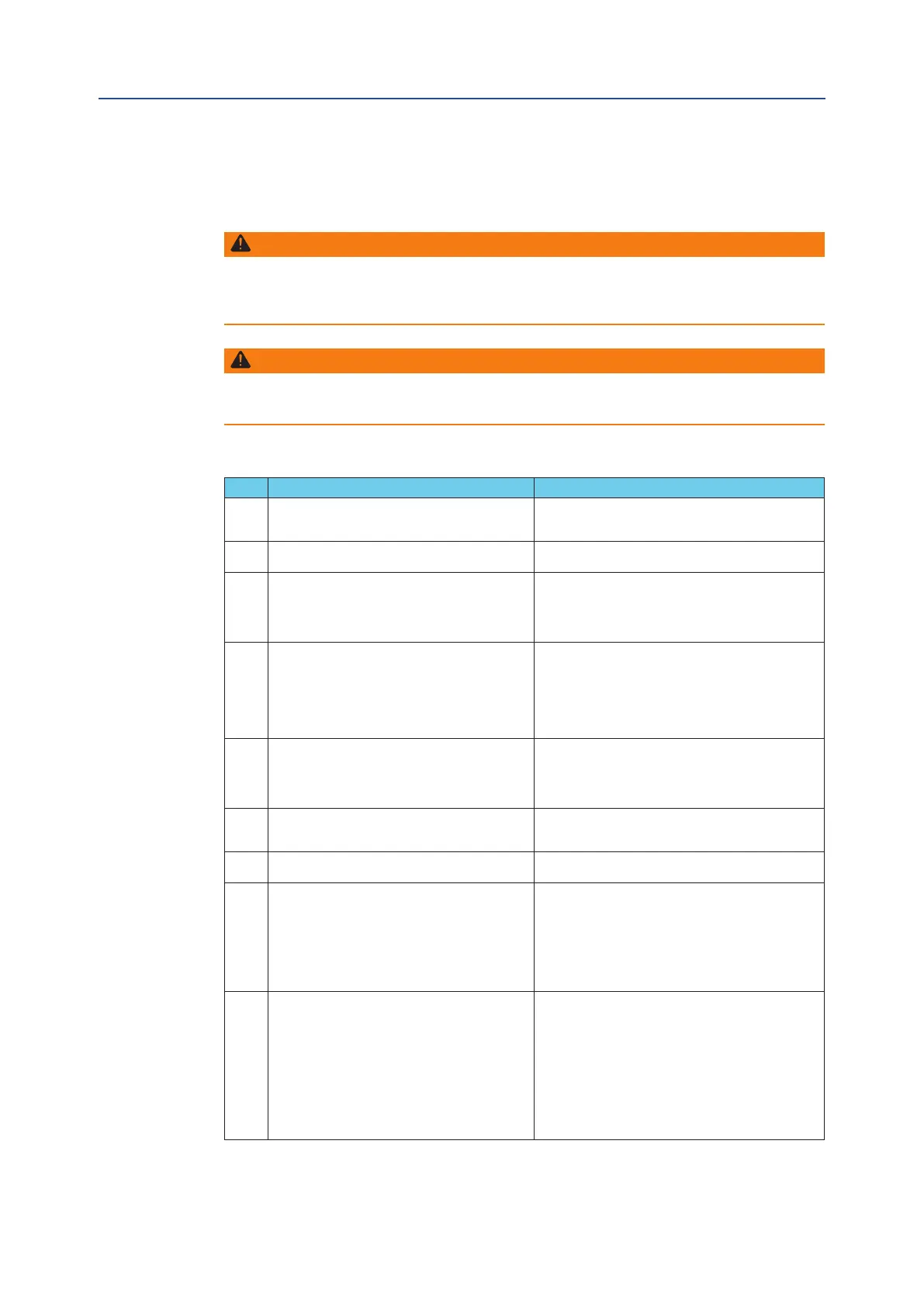

Table 17.

# Detected problem Actions to be performed

1 THE IMVS DOES NOT SWITCH ON WHEN POWERED

• verify the Main Supply on terminals 3 & 4.

• verify that the wiring is correct.

• verify the Display Card cable is connected.

2 THE IMVS DOES NOT WORK FROM LOCAL CONTROLS

• verify the integrity of the Display Card cable.

• Device already connected to Biffi Assistant.

3 THE IMVS CAN NOT MOVE THE ACTUATOR

• verify the wiring is correct.

• verify the pneumatic or hydraulic connections.

• verify the supply on terminals 5-6 and 12-13

(if connected).

• verify the supply pressure of the actuator.

4 NO OUTPUT VOLTAGE TO THE SOLENOID VALVE(S)

• verify that the wiring is correct.

• verify the supply on terminals 5-6 and 12-13

(if connected).

• verify that the voltage on terminals 8-9-10 and

16-17-18 respects the polarity (±).

• verify that available power (Watts) of power supply

source is correctly sized.

5

THE LOCAL POSITION INDICATOR IS NOT CONSISTENT

WITH ADHESIVE LABEL

• remove the base cover (see 10).

• remove the position indicator (just pull the item to

disassembly from the position sensor).

• rotate the position indicator 90 degrees.

• install again the cover and tighten the screws.

6

THE IMVS DOES NOT IDENTIFY CORRECT TRAVEL

LIMITS OR ACTUATOR POSITION

• perform a Calibration.

• verify the mechanical coupling of the IMVS to the

actuator: no clearance must exist.

7 THE IMVS GETS NO PRESSURE INDICATION

• verify the tubing between IMVS and actuator.

• verify the supply pressure of the actuator.

8 THE IMVS CAN NOT PERFORM THE BASELINE PST

• verify the Main Supply on terminals 3 & 4.

• verify that the wiring is correct.

• verify the supply on terminals 5-6 and 12-13.

(if connected)

• verify that the voltage on terminals 8-9-10 and

16-17-18 respects the polarity. (±)

• verify that “Base. S. St.” = “Passed.”

• verify that “PST En.” = “Yes.”

8 THE IMVS CAN NOT PERFORM THE BASELINE SIGNATURE

• verify the Main Supply on terminals 3 & 4.

• verify that the wiring is correct.

• verify the supply on terminals 5-6 and 12-13.

(if connected)

• verify that the voltage on terminals 8-9-10 and

16-17-18 respects the polarity. (±)

• verify the pneumatic or hydraulic connections.

• verify the supply pressure of the actuator.

• verify that “Cal. Status” = “Passed.”

• verify that “Sign. En.” = “Yes.”

102

Loading...

Loading...