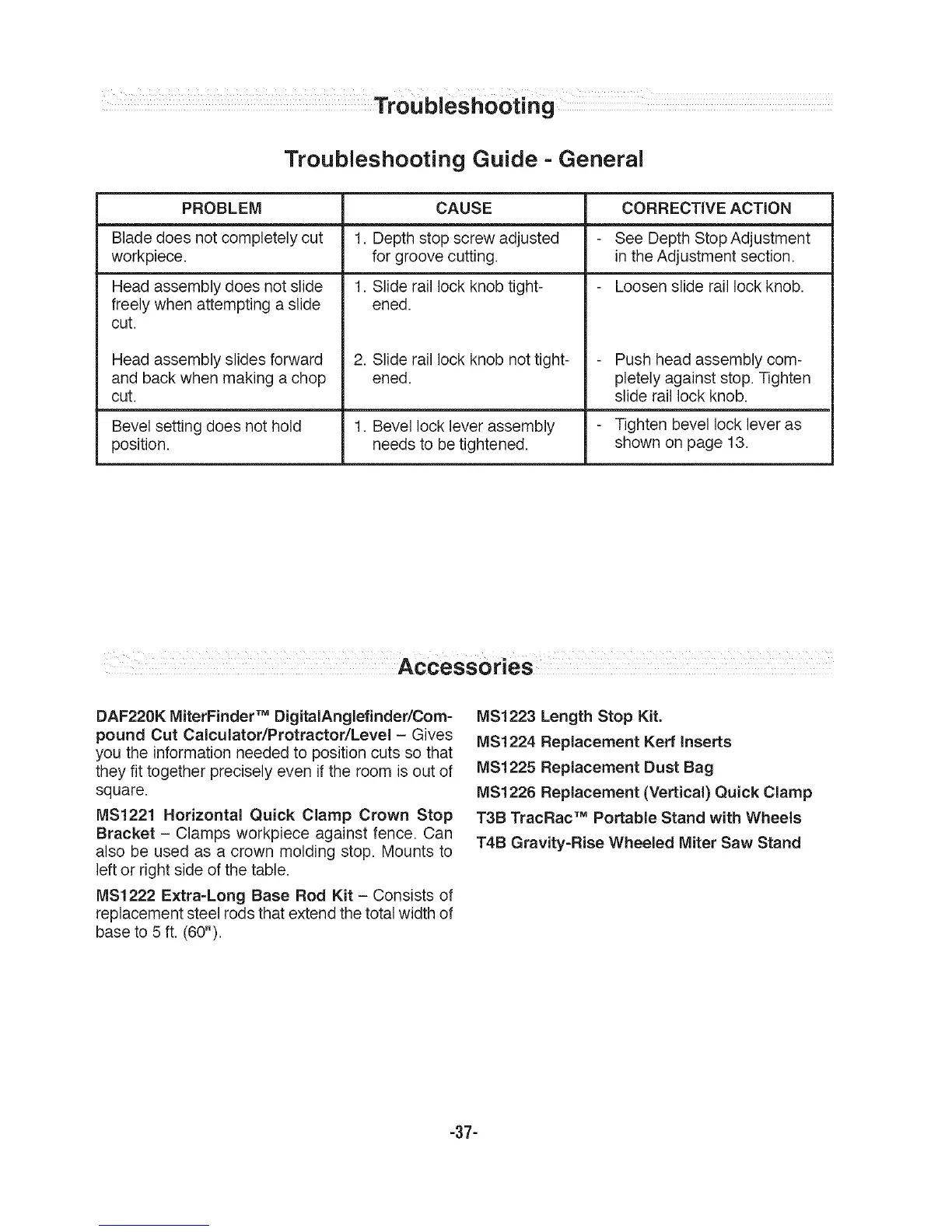

Troubleshooting Guide - General

PROBLEM CAUSE CORRECTIVE ACTION

Blade does not completely cut 1. Depth stop screw adjusted See Depth Stop Adjustment

workpiece, for groove cutting, in the Adjustment section.

Head assembly does not slide 1. Slide rail lock knob tight- Loosen slide rail lock knob.

freely when attempting a slide ened.

cut.

Head assembly slides forward 2. Slide rail lock knob not tight- Push head assembly corn-

and back when making a chop ened. pletely against stop. Tighten

cut. slide rail lock knob.

1.

Bevel setting does not hold

position.

Bevel lock lever assembly

needs to be tightened.

Tighten bevel lock lever as

shown on page 13.

DAF220K MiterFinder TM DigitalAnglefinder/Com-

pound Cut Calculator/Protractor/Level - Gives

you the information needed to position cuts so that

they fit together precisely even if the room is out of

square.

MS1221 Horizontal Quick Clamp Crown Stop

Bracket - Clamps workpiece against fence. Can

also be used as a crown molding stop. Mounts to

leftor right side of the table.

MS1222 Extra-Long Base Rod Kit - Consists of

replacement steel rods that extend the total width of

base to 5 ft. (60").

MS1223 Length Stop Kit,

MS1224 Replacement Kerr inserts

MS1225 Replacement Dust Bag

MS1226 Replacement (Vertical) Quick Clamp

T3B TracRacTM Portable Stand with Wheels

T4B Gravity-Rise Wheeled Miter Saw Stand

-37-

Loading...

Loading...