-41-

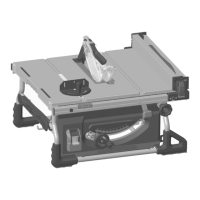

Making Work Helpers

Before cutting any wood on your saw, study all of

the information in “Basic Table Saw Operations.”

Notice that in order to make some of the cuts, it is

necessary to use certain devices, “Work Helpers”,

like the Push Stick 95, the Push Block 96 and the

Auxiliary Fence 97, which you can make yourself.

After you have made a few practice cuts, but be-

fore starting any projects, make these work help-

ers. Make the “push stick” rst.

Making the Push Stick and Push Block

(Fig. 57, Fig. 58)

Make the Push Stick 95 using a 1″ x 2″ (19 mm x

38 mm) piece as shown in Fig. 57. For proper use

of a Push Stick 95, see “Using the Push Stick” on

page 45.

Make the Push Block 96 using pieces of

3/8″(8.7 mm) plywood A and 3/4″ (19 mm) hard-

wood B. The Push Block 96 is only to be used in

combination with the auxiliary fence. For proper

use of Push Block 96, see “Using the Push Block

with the Auxiliary Fence” on page 46.

The small piece of wood, 3/8″ x 3/8″ x 2-1/2″ (9.5 x

9.5 x 63.5mm), should be GLUED to the plywood…

DO NOT USE NAILS. This is to prevent dulling the

Blade 31 in the event you mistakenly cut into the

Push Block 96.

Position the handle in the center of the plywood

and fasten them together with glue and wood-

screws.

Use the Push Stick 8 whenever the Rip Fence 9 is

2″ (50 mm) or more from the Blade 31. Use a Push

Block 96 when the operation is too narrow to allow

the use of the Push Stick 8. For proper use, see

“Using the Push Stick, Push Block, and Auxiliary

Fence“ on page 45.

Push Stick 8 or Push Block 96 should be used only

between the Rip Fence 9 and the Blade 31.

When using the Push Stick 8 or a Push Block 96,

the trailing end of the board must be square. The

Push Stick 8 or a Push Block 96 against an uneven

end could slip off or push the work away from the

Rip Fence 9.

Basic Table Saw Operations

Anti-Kickback Device

(Fig. 55)

In the event of kickback, the Anti-Kickback Device

27 is intended to help prevent the workpiece from

being thrown in the direction of the user. The sharp

teeth of the Anti-Kickback Device Pawls 49 are in-

tended to “catch” the material in the event of kick-

back.

The Anti-Kickback Device 27 can be easily attached

by aligning the attachment pin with the hole in the

rear of the Riving Knife (Splitter) 25. It can be eas-

ily removed by depressing the Compression Pin 48

on the side of the Anti-Kickback Device 27 and lift-

ing it away.

1609B07947_GTS15-10_Table_Saw_OSI_20230420.indd 411609B07947_GTS15-10_Table_Saw_OSI_20230420.indd 41 4/20/2023 11:23:42 AM4/20/2023 11:23:42 AM

Loading...

Loading...