Service Manual 04/2010 Rev.B

56

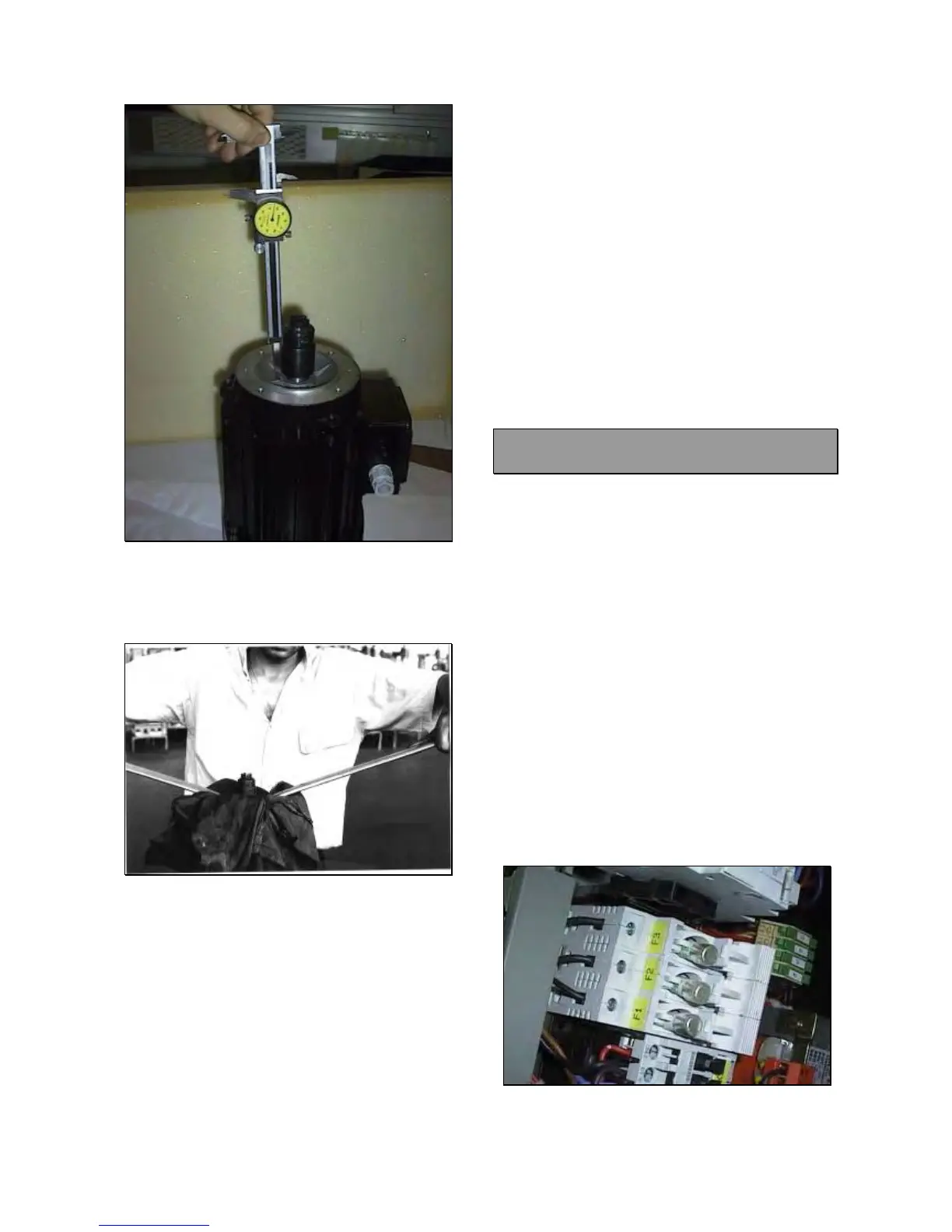

Fig.71

Lose the 3mm Allen screws of the joint and

remove it from the motor shaft by using two

levers (Fig.72).

Fig.72

Take the new motor.

Mount the joint following the distance

previously verified and lock it.

IMPORTANT!

A WRONG REGULATION OF THE JOINTS

WILL CAUSE HYDRAULIC PUMP DAMAGING

OR DAMAGING OF JOINTS THEMSELVES

WITH A CONSEGUENT NO HYDRAULIC

MOVEMENTS.

Mount the aluminium spacer: There is a little

hole in a face and this face must be mounted

downwards in order to show immediately if

there is an inner oil leaking.

Mount the motor on the hydraulic assy.

Connect the wires FIRMLY to motor terminals

following the voltage at which the machine is

supplied.

NOTE: Before connecting the wires ends, tighten

all terminals nuts.

Check the rotation way of the motor: If it is

wrong reverse only two motor wires otherwise

the chuck motor will turn wrongly.

Mount the motor terminals cover.

IMPORTANT: WHEN REMOUNTING THE

MOTOR TERMINALS COVER BE CAREFUL

NOT TO CRUSH WIRES.

5.6 FUSES F1, F2, F3: CHECK AND

REPLACEMENT

: 30’

: Multimeter

L : Defective fuse/s may cause the following

malfunction:

1. Chuck motor does not run at all.

TO CONTROL AND REPLACE THE FUSES:

Disconnect the machine from power supply.

Open the electric box (5.0).

Open the protection and remove the fuse

(Fig.73).

Verify if there is continuity between the ends

of each fuse.

If necessary, replace them with fuses of the

same value: 25A 500V.

IMPORTANT!

ON NON CE PROVED VERSIONS, THE CHUCK

MOTOR PROTECTION IS REPLACED BY A

CIRCUIT BREAKER (5.3).

Fig.73

Loading...

Loading...