Service Manual 04/2010 Rev.B

72

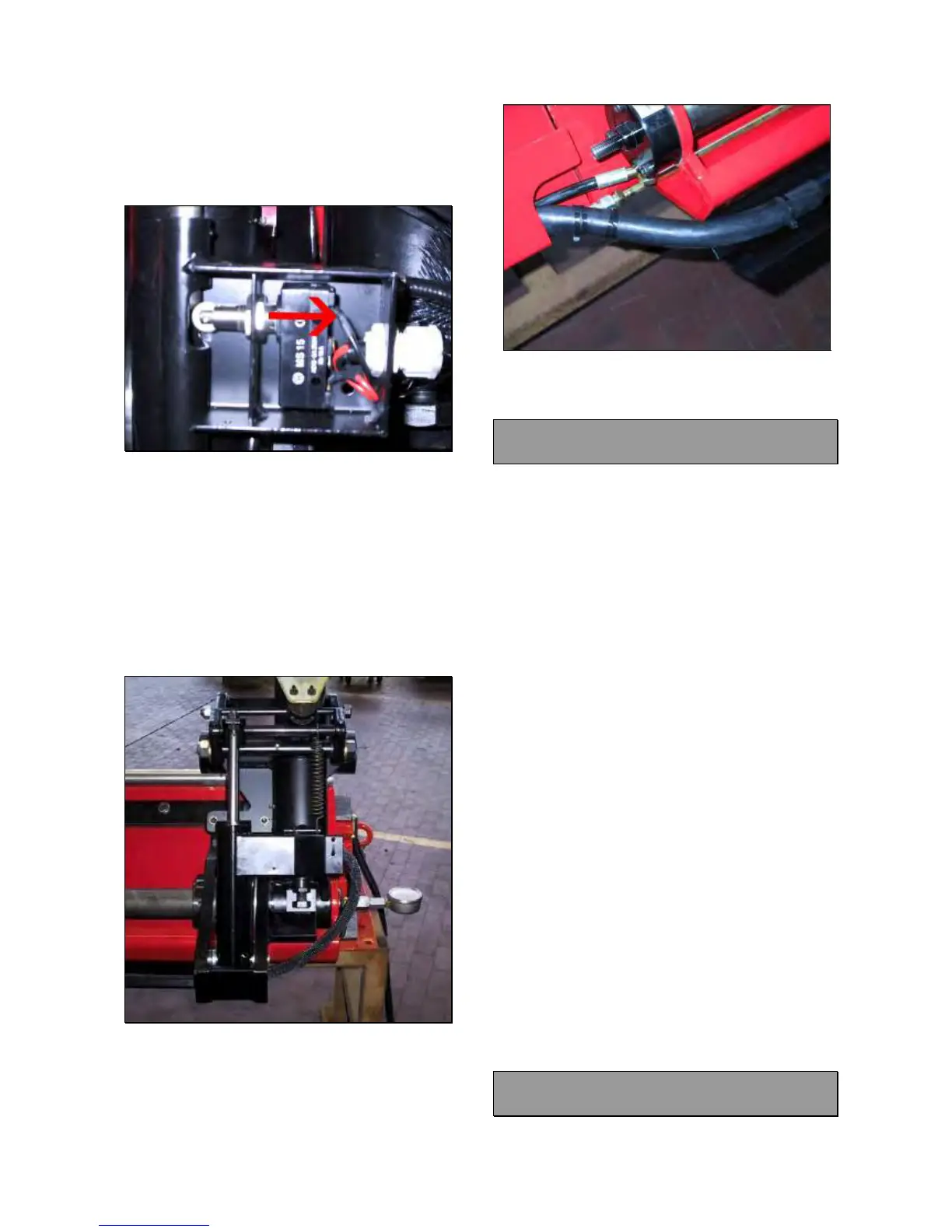

Lower all way down the tool holder ‘till to have

its cylinder at the end of the stroke: all function

of the machine should work normally. If not

move a little the switch by following the arrow

in Fig.119.

Fig.119

Tighten the cable strein relief.

Mount the switch cover and fit the hoses with

a clip hose (Fig.114).

IMPORTANT: WHEN FIXING THE SWITCH

COVER, BE CAREFUL NOT TO CRUSH

WIRES.

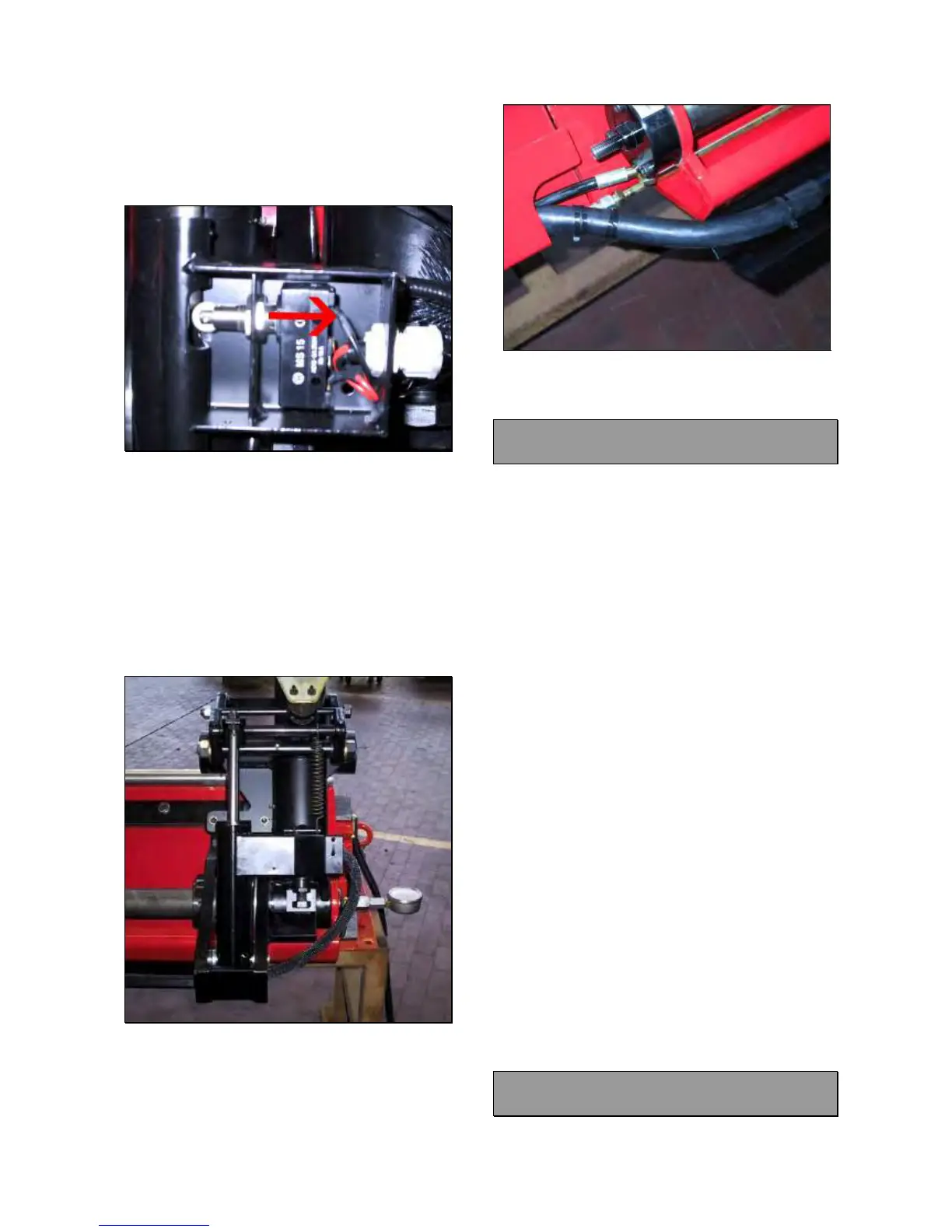

Move the tool holder ‘till end of the stroke and

leave some hoses free (Fig.120)

Fig.120

Lock the hoses on their protection and mount

the rubber tube (Fig.121)

Install the protection (Fig.115).

Mount the plastic spring around the hoses.

Fig.121

Check if the machine works fine.

5.22 ROBOTIC SAFETY SWITCH :

CHECK AND REPLACEMENT

: 1h

: Small standard and cross screwdrivers,

3mm allen wrench, 6mm end wrench, pliers,

multimeter.

L : Defective switch may cause the following

malfunction:

1. All hydraulic movements, except tool holder

lifting and lowering, do not work.

TO CONTROL THE SWITCH:

Switch the machine on.

Lower the tool holder arm and hook it.

Make sure to have the hook cylinder at the

end of stroke.

Turn off the machine and open the electric

box.

Disconnect the wires 20 and 21 from terminal

block (Fig.110).

Take the multimeter and select it in Ohm.

Verify if there is continuity between the wires

20 and 21.

If there is not continuity the switch must be

replaced.

IMPORTANT!

BEFORE STARTING WITH SWITCH

REPLACEMENT VERIFY IF IT IS WELL

REGULATED AND VERIFY IF THE WIRE IS

FINE.

TO REPLACE THE SWITCH:

Replace the switch following 5.21

5.23 COIL CONNECTOR CABLE:

CHECK AND REPLACEMENT

Loading...

Loading...