ENGLISH 18 / 78 CAP. 6 - MAINTENANCE

CAP. 6 - MAINTENANCE

6.1 EQUIPMENT MAINTENANCE

The interventions foreseen for periodical and preventive maintenance are listed as follows:

• “LONG LIFE PUMP” special function and VACUUM PUMP OIL change

• DRYER FILTER replacement (every 45 kg of recovered gas)

• Wear check of the RED and BLUE CHARGE HOSES (4.5 m) and the HP RED and LP BLUE

QUICK COUPLERS

• Refrigerant gas scale check with sample weight and calibration, if needed, (SERVICE KIT)

• New oil scale check with sample weight and calibration, if needed, (SERVICE KIT)

• Exhausted oil scale check with sample weight and calibration, if needed, (SERVICE KIT)

• Wear and tightness check of the manifold solenoid valve pistons

• Wear check of the OR2-106 4.42x2.62 NBR O-RING of the pressure sensor present on the

MANIFOLD

• Presence and wear check of the OR2212 53,7x1,78 NBR O-RINGS of the oil and tracer

containers

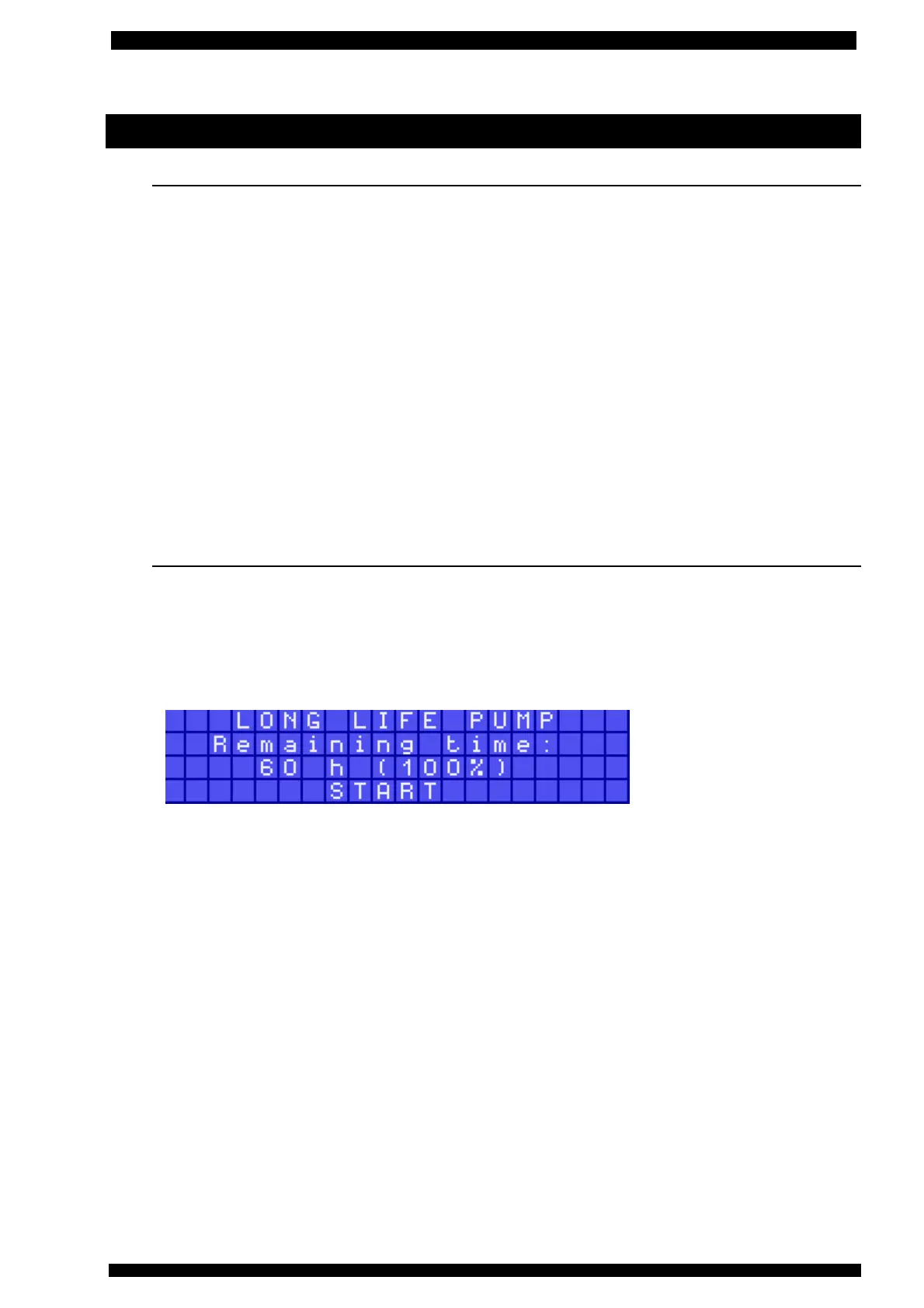

6.2 “LONG LIFE PUMP” SPECIAL FUNCTION - VACUUM PUMP

OIL CHANGE

The tool is equipped with a special function named LONG LIFE PUMP that enables to

optimize the use of vacuum pump oil, avoiding the replacement every 60 hours of operation.

LONG LIFE PUMP is a Brain Bee patented special function allowing to extend up to 1000

hours the life of the pump oil used in the station.

LONG LIFE PUMP function performance is suggested at the end of 60-hour operation

intervals of the vacuum pump and can be manually activated in the MAINTENANCE menu.

LONG LIFE PUMP procedure has to be started only after checking and, if necessary, topping

up the pump oil level and lasts 1 hour: during this time the tool cannot be used.

During the procedure the oil is automatically purified from the gaseous polluting residues

absorbed during the emptying operations of vehicles air conditioning systems.

At the end of the procedure, the vacuum pump performance check is carried out and a result

is shown to the operator.

In case of negative result you have to replace the vacuum pump oil.

After 1000 hours of vacuum pump operation since the last oil change, LONG LIFE PUMP

procedure cannot be activated anymore and you have to replace the oil according to the

following described modes.

Required equipment:

1 Medium-sized cross-tip screwdriver

1 Medium size flathead screwdriver

1 Hex key (10 mm)

For replacement, comply with the instructions outlined below:

Unplug the unit from power mains.

Remove the screws that fix the front door of the unit and remove it.

Loading...

Loading...