ENGLISH 26 / 78 CAP. 6 - MAINTENANCE

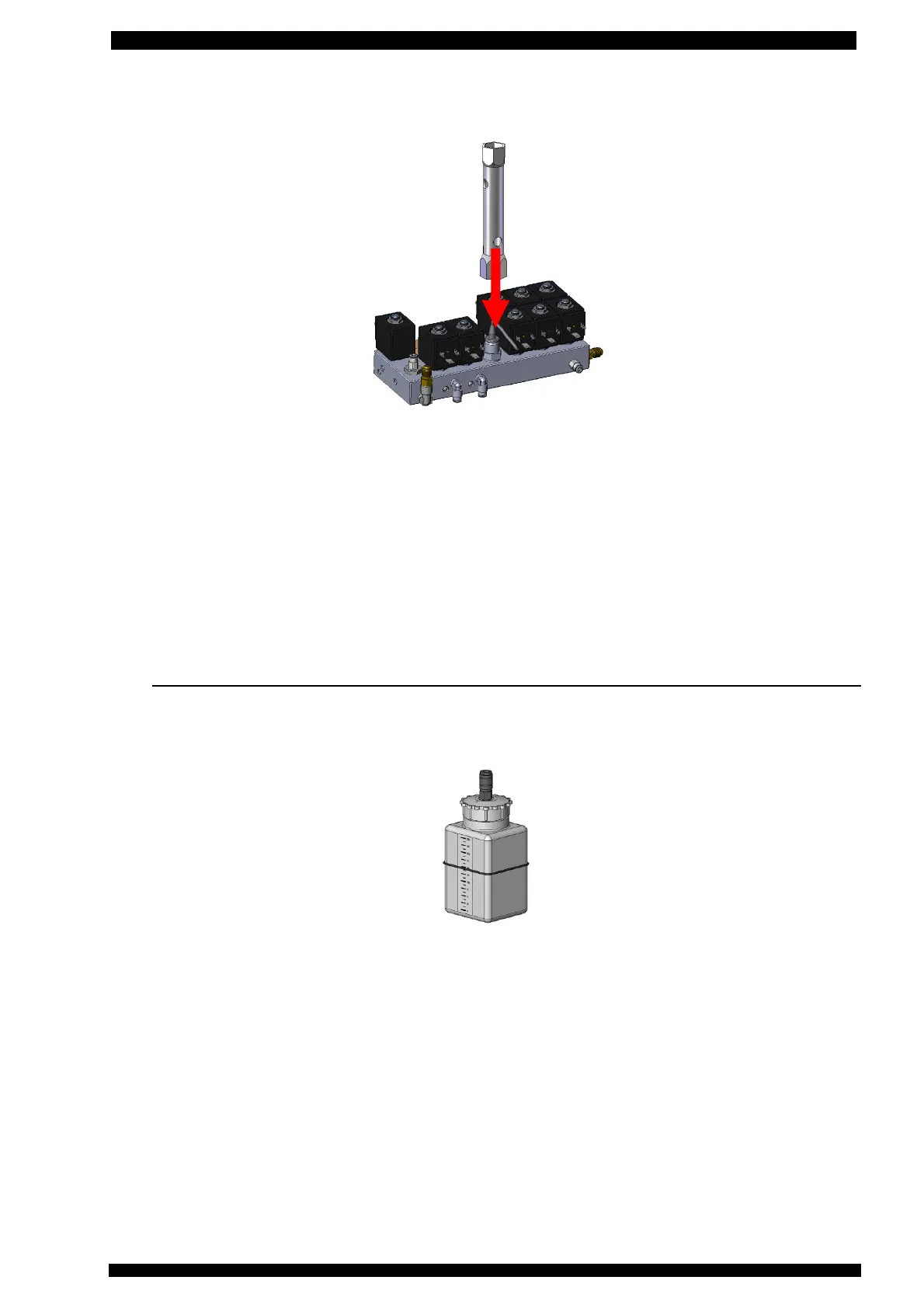

17. Once the solenoid valve mounting is complete, reopen the taps/valves of the tank

18. Close panel and cover, reconnect the power supply cable and turn on the machine again.

TEST UNDER PRESSURE

From the Service Menu “Manual activations”, in relation to the replaced valve, open (activate) or

keep closed the solenoid valves represented in the chart reported as follows.

Ensure that the tank pressure reaches the sensor being serviced.

Check that the sensor in question does not present refrigerant leaks through the identification of

leaks or pressure drops.

TEST IN VACUUM

Launch the function inside the Maintenance Menu “Leak test”, check that the test is passed

successfully.

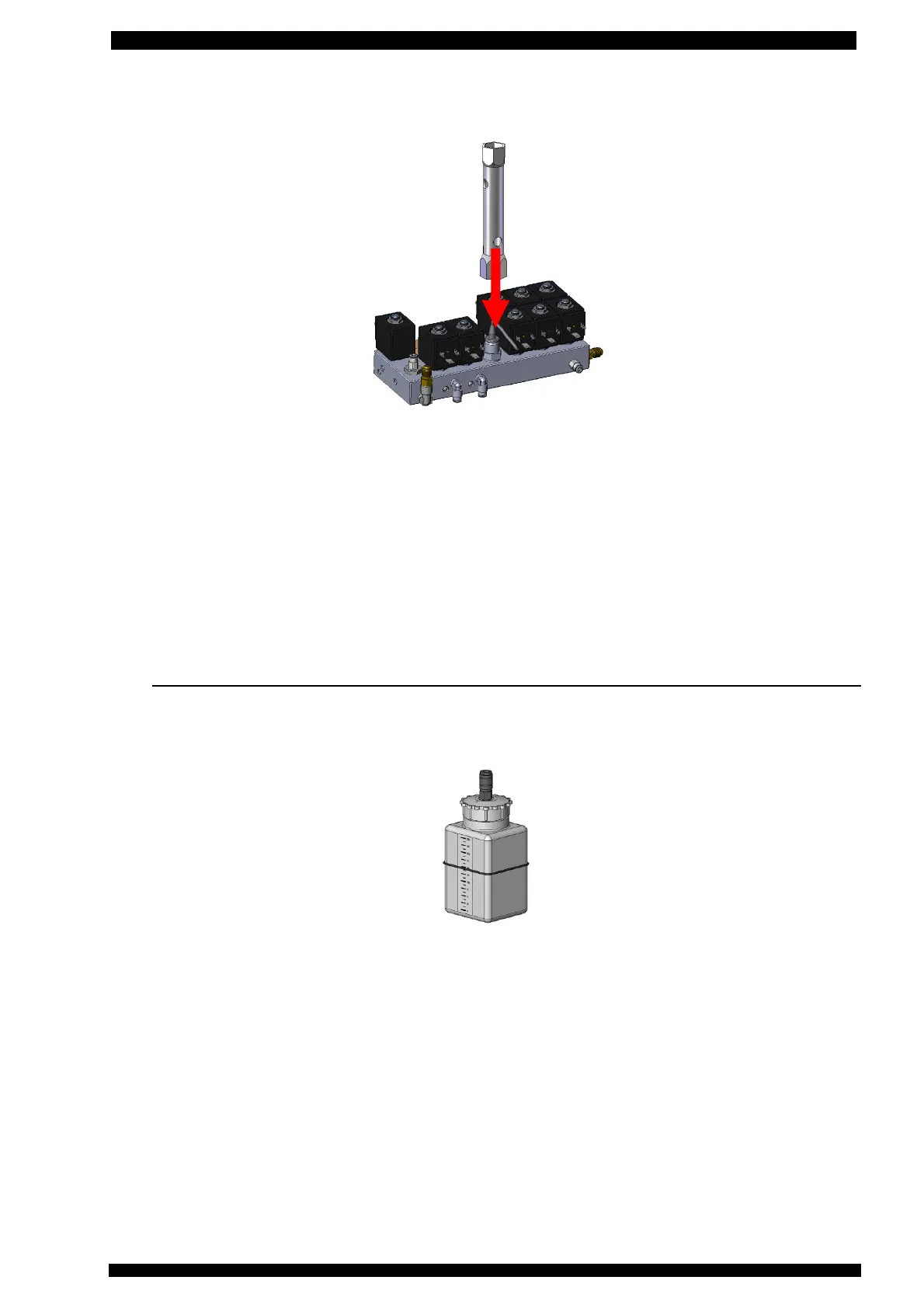

6.10 PRESENCE AND WEAR CHECK OF THE OR2212 53,7x1,78

NBR O-RINGS OF THE OIL AND TRACER CONTAINERS

Check the presence of the O-RING, which acts as sign of the oil level on new, exhausted and tracer

oil containers. In case of signs of deterioration replace them with new ones.

In case of problems when inserting the connector on the machine joint, replace the bottle.

Loading...

Loading...