ENGLISH 20 / 78 CAP. 6 - MAINTENANCE

These types of oil must ensure:

• high viscosity index, which minimizes viscosity variations when temperature changes. This

means, in cold conditions, promptness and sensitivity of control and, at the same, time, in

warm conditions, stability of operation.

• Remarkable wear-prevention properties, ensuring a long life of moving parts.

• Excellent defoaming power, which limits noise level, irregular operation, impossibility of

reaching the final pressure.

• Great chemical stability, ensuring oil can be used for longer periods without causing

formation of oxidization products, such as mud and sludge.

• Strong rust preventive properties, which ensure effective protection of metal surface against

corrosion caused by the action of humidity present in the pumped fluid.

IMPORTANT

The described oils for vacuum are of mineral origin and, as such, are fuels. If during normal

use, the vacuum pump shall suck up mixtures containing oxygen above 21% or pure oxygen,

this would lead to oil oxidation and thus to a loss of lubricating properties, with significant

damage to the pump itself.

Physical and chemical properties

Physical status: Liquid

Appearance: Crystal clear (visual)

Odour: Typical pH in aqueous solution (conc.): Not applicable

Solubility in water: Insoluble

Density at 15°C kg/l: 0.890 (ASTM D1298)

Kinematic viscosity at 40°CcSt: 68 (ASTM D445)

Flammability point (COC)°C 220: ( A STM D92)

Pour point °C: -9 (ASTM D97)

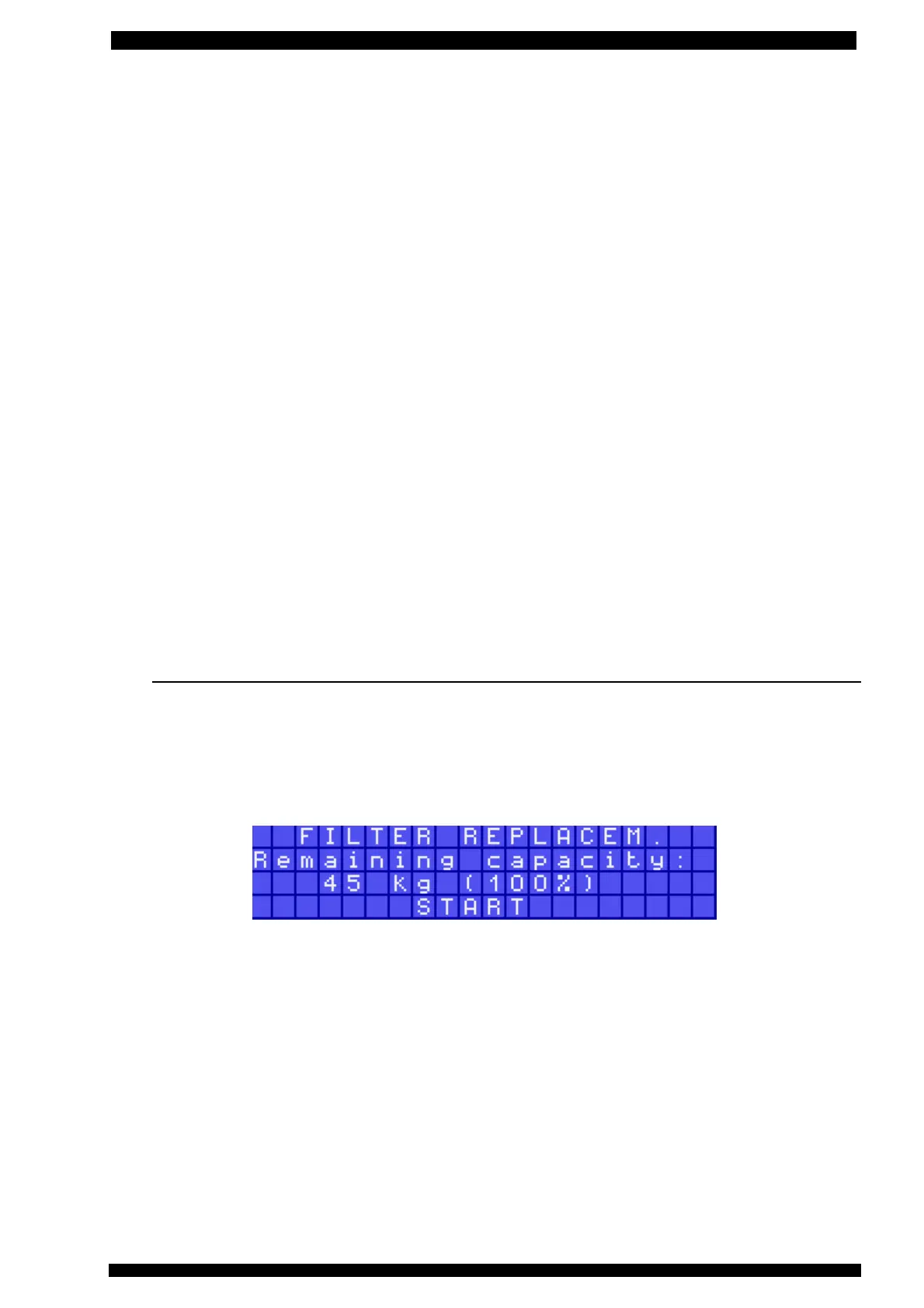

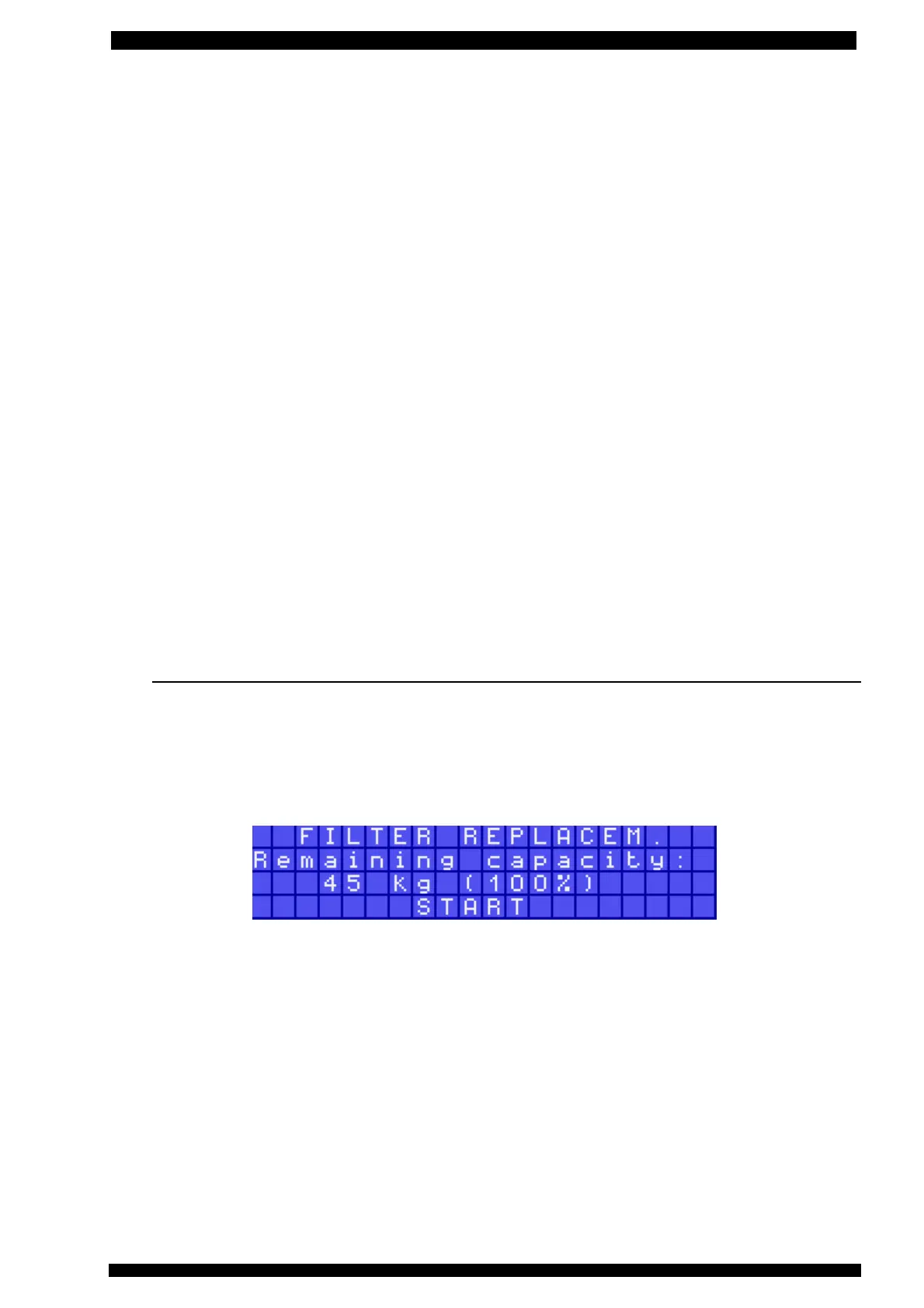

6.3 DRYER FILTER CHANGE

The dryer filter shall be replaced once 45 kg of refrigerant fluid have been dehydrated, because the

filter depletes its capacity of retaining the moisture present in the refrigerant.

To replace the dryer filter, from the MAINTENANCE menu select DRYER FILTER REPLACEMENT:

press “RESET” to set the counter to zero and to start the filter replacement procedure.

Now you can replace the filter.

Required equipment:

• 1 Medium-sized cross-tip screwdriver

• 1 regular or torque Hex wrench (24 mm)

• 1 Hex key (17 mm)

Loading...

Loading...