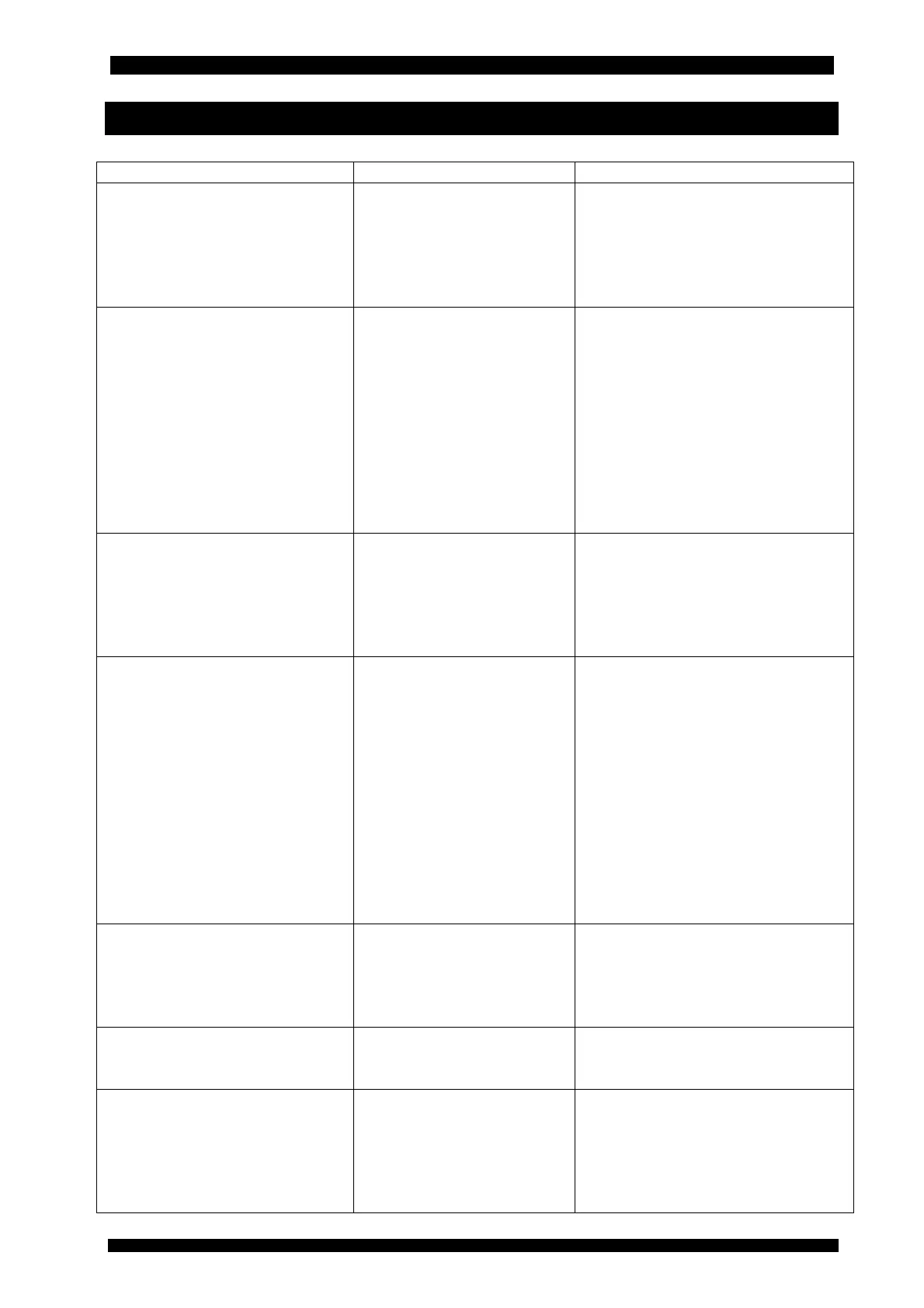

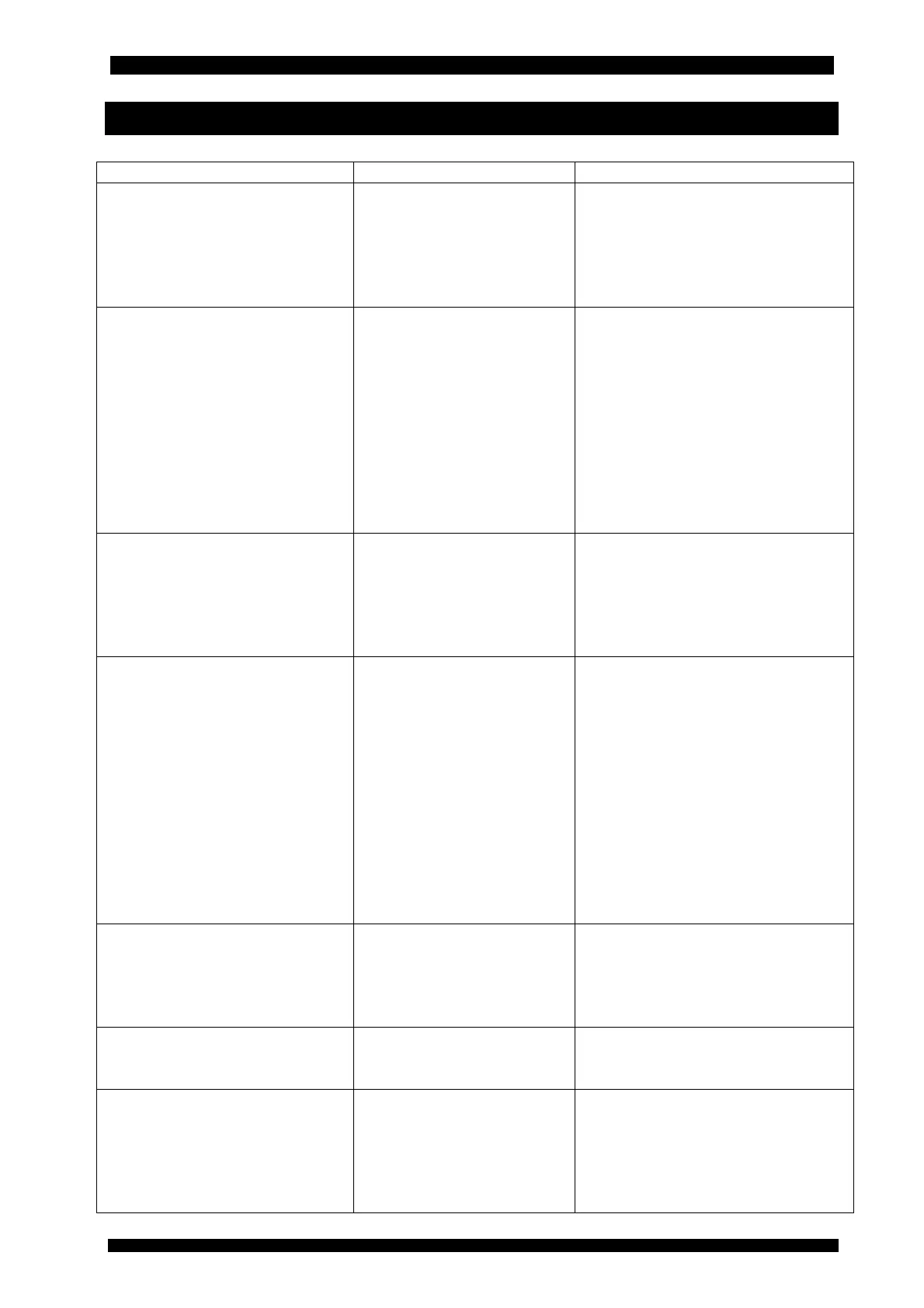

ENGLISH 72 / 78 CAP. 16 - TROUBLE SHOOTING

CAP. 16 - TROUBLE SHOOTING

MALFUNCTION POSSIBLE CAUSE POSSIBLE SOLUTION

1. If the “SD card not present”

message is shown during switch

on and/or during software

update just downloaded from

the web.

SD card absent or not

mounted well.

1. Insert or check SD card

insertion.

2. Reprogram the recharge station.

2. Slow or not possible

refrigerant injection.

Joints seal gaskets cut for

excessive tightening (they

cause clogging of pipes

and operational block of

the machine, with different

consequences based on

the position of the gasket -

in any case it is always

related to clogging of a

pipe or dirt in the solenoid

valves).

1. Localisation of the defects of the

rubber components or dirt residue

and replacement or cleaning.

2.Carry out emptying of the gas as

described in chap.13.2.1

3. If yellow pipes are present,

check and, if needed, replace the

seal gaskets placed inside the pipe

which connects the solenoid valves

group to the tank.

3. During the recovery phase

there is an evident refrigerant

leak from the exhausted oil

container.

The leak test is negative.

Dirt inside the Oil

discharge solenoid valve.

1. Cleaning of the solenoid valve

OUT – S.

2. Check of the gasket efficiency.

3. calibrate pressure sensor

4. Difficulty in the recovery and

recharge phase

Closed refrigerant tank.

Seal gaskets, broken or

deformed, are obstructing

the pipes.

1. Open the tank valve by

unscrewing it counter clockwise.

2.Carry out emptying of the gas as

described in chap.13.2.1

3. Reset the normal seal conditions

of the HP-LP taps gaskets and the

HP-LP couplers, both internal and

external.

4. If yellow pipes are present,

check and, if needed, replace the

seal gaskets placed inside the pipe

which connects the solenoid valves

group to the tank.

5. During the automatic cycle it

is not possible to inject and

recover the oil.

Oil loading cell out of

calibration or defective.

1. Calibration of the exhausted

and new oil scales.

2. Replace if needed.

6. Vacuum pump emits

disturbing vibrations

Defective vacuum pump Vacuum pump replacement

7. After the vacuum phase the

leak test has a negative result.

This may occur when the

vacuum time is too short,

4-5 minutes.

When a vacuum time less than 20

minutes is set, the following

message appears:

“Less than 20 minutes of vacuum

do not guarantee the execution of

a correct procedure. Continue?”.

Loading...

Loading...