Classic Cycles Technical Resources

11

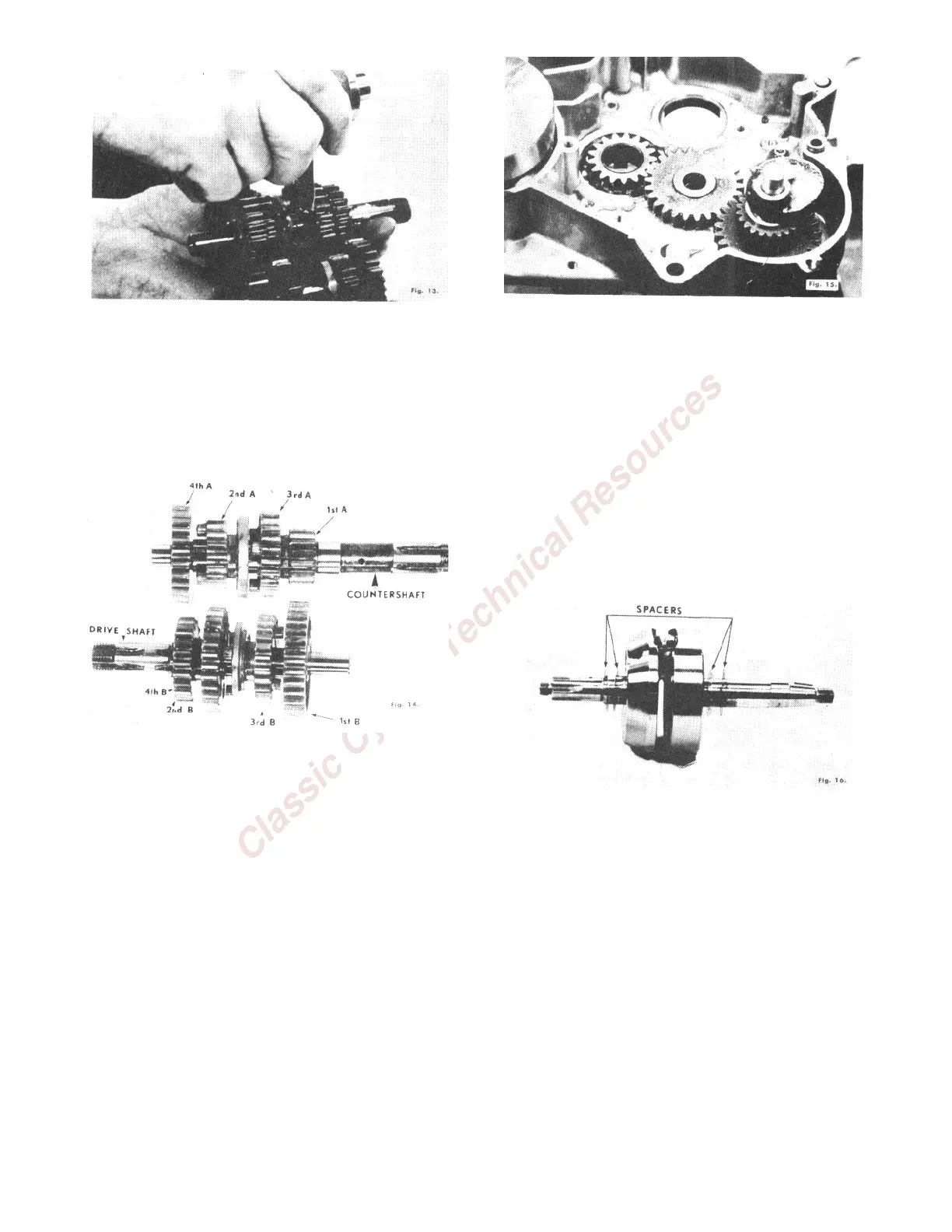

53. Inspect the two transmission shafts and gears

to be certain that they are all in good

condition. Further disassembly of the

transmission is not necessary unless one or

more of the gears must be replaced. If this is

necessary, carefully note the position of the

gears on the shaft before removing them for

replacement. (Fig. 14)

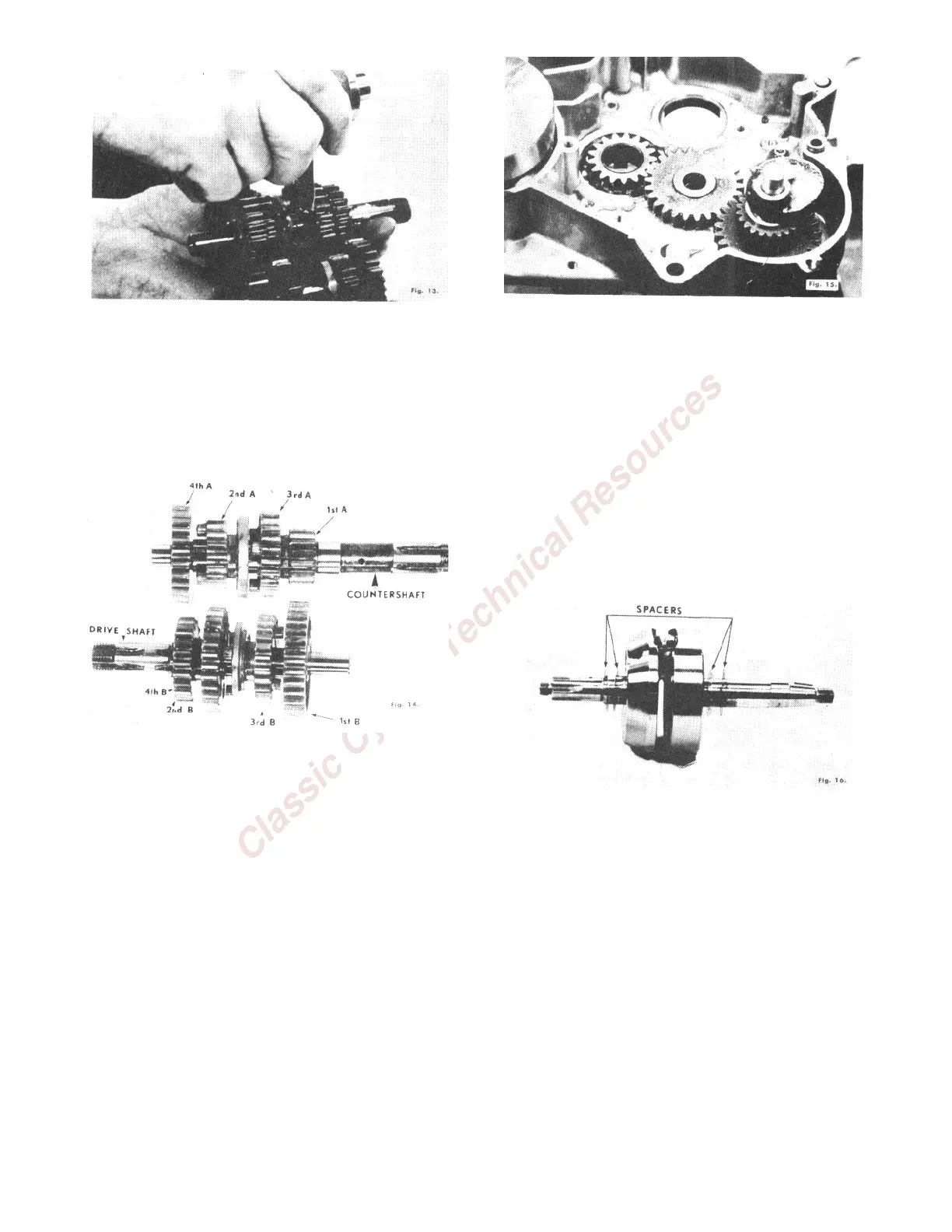

54. Remove the kick starter intermediate gear

which remains in the crankcase half after the

transmission shaft assembly has been

withdrawn. Note that there is a spacer above

and below this gear. Keep these spacers with

this gear to facilitate reinstallation. (Fig. 15)

55. Withdraw the kick starter shaft and gear

assembly. Notice that there is a spacer on the

end of this shaft. Keep the spacer with this

shaft to facilitate reassembly.

56. Withdraw the crankshaft assembly. Notice

that spacing shims are used on either side of

the crankshaft balance assembly. (Fig. 16) If

the same crankshaft is to be replaced, keep

these spacers on the crankshaft so that the

crankshaft end play will not be affected. The

number and thickness of spacers on this

crankshaft varies from engine to engine.

Occasionally the spacing shims will stick to

the crankshaft bearings. Inspect the bearings

carefully to be certain that these shims have

been removed from both the crankcase

sections if the oil present has caused them to

adhere to the bearings.

This completes the disassembly operation. Wash

all parts (except magneto armature plate) in a

cleaning solvent and inspect all bearings and oil

seals. If it is necessary to replace bearings, the

crankcase must be heated with a small torch in

the vicinity of the bearings to expand it

sufficiently to allow the bearing to be removed

and replaced. When using a torch, keep the torch

constantly in motion to avoid melting the

crankcase castings.

If oil seals are to be replaced, coat them liberally

with oil and tap them into place with a small

hammer. Before beginning the reassembly

operation, oil all bearings and oil seals

thoroughly.

Loading...

Loading...