Classic Cycles Technical Resources

57

2. For chronic problems caused from the cycle being driven only at very low speeds, the charging coil from

the B/S 7 Standard can be installed to increase charging.

NOTE: When either method is used, battery water should be checked frequently and water added as

necessary.

ELECTRICAL EQUIPMENT – 175 DT

The ignition system consists of contact breakers, condensers, ignition coil, spark plugs, etc. Battery low

voltage current is converted to high voltage current by the ignition coil. High voltage current is supplied to

the spark plug and, when timed by the contact breakers, ignites the fuel mixture in the cylinder.

Contact Breakers: Two contact breakers are fitted on the AC dynamo. The AC dynamo is turned through

the pinion drive gear, driven gear and timing gear. The timing gear turns one full revolution when the

crankshaft turns two full revolutions. The timing gear and point cam are fixed on the dynamo shaft and

turn with it. The engine of the BS 175 DT is a two-stroke two cylinder engine so two explosions occur every

time the crankshaft makes one full revolution. As the speed of the AC dynamo is one-half of that of the

crankshaft, contact points must supply four sparks for each revolution of the dynamo, so two cams and two

sets of contact breakers are installed. One contact breaker opens each 90E (¼ turn) of cam rotation and high

voltage current is induced in the ignition coil.

Contact breaker points should be kept bright and

smooth. If point surfaces are rough or pitted, polish

lightly and evenly on an oil stone until the surfaces are

smooth. (If points cannot be repaired, replace with new

ones.) After polishing, wash the point surfaces with

gasoline or thinner and wipe dry with a clean cloth.

Ignition timing:

• NOTE: Do not attempt to adjust left timing until

right timing is completed. Movement of generator

during right cylinder timing adjustment will change

left timing.

TO CHECK TIMING - RIGHT CYLINDER

1. Remove spark plugs.

2. Remove left carburetor air pipe.

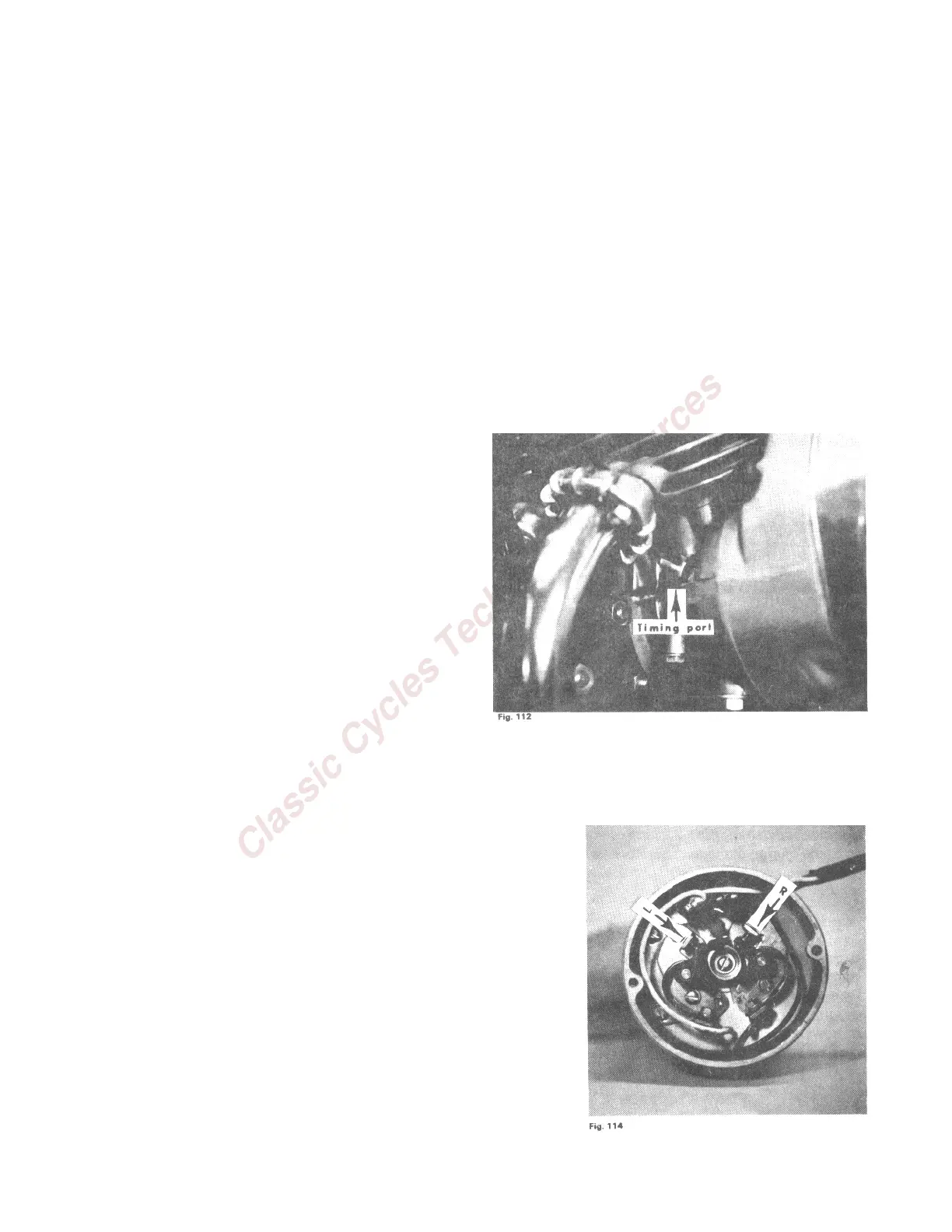

3. Remove point cover from left end of generator and adjust both

sets of points to .012"-.016" at their widest point.

4. Rotate crankshaft by putting transmission in 4th gear and

turning rear wheel until the right piston is at top dead center as

viewed through the spark plug hole.

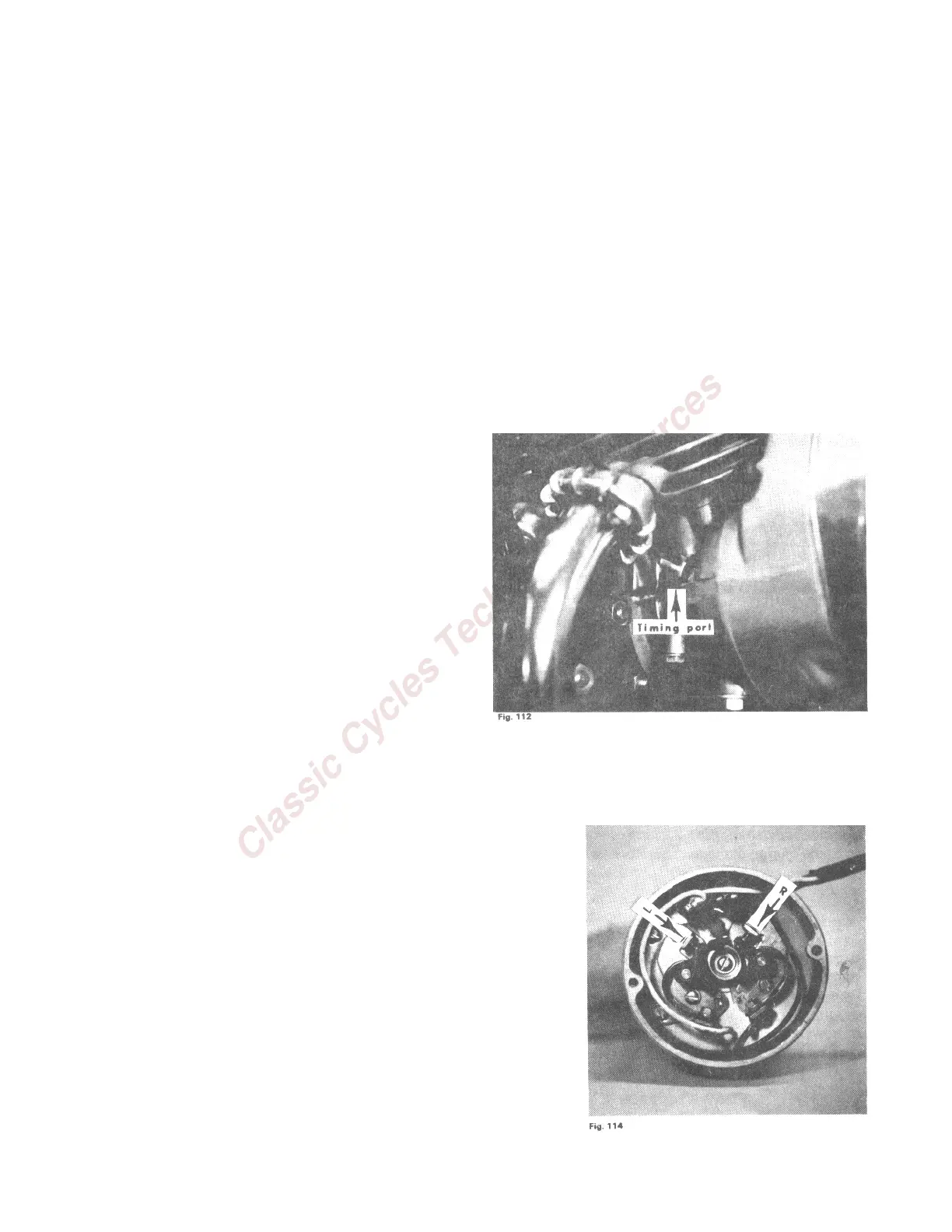

5. Install timing screw and bar into timing hole at front of engine

(fig. 112). This item is packed in the cycle tool kit.

6. Connect one lead wire of a continuity test light to the right point

condenser lead wire at the condenser with the key switch in the

off position. (Test light is now off) The other test light lead wire

is grounded to engine.

Loading...

Loading...