26

The cylinders of the 30-60 SPT, 90 STD, 90 T, 90 M are of high-grade cast iron and accurately finished by

honing.

In the 90 SPT and 175 DT, the cylinders are made of aluminum alloy. Cylinder walls are honed after hard

chromium plating and then porous treated.

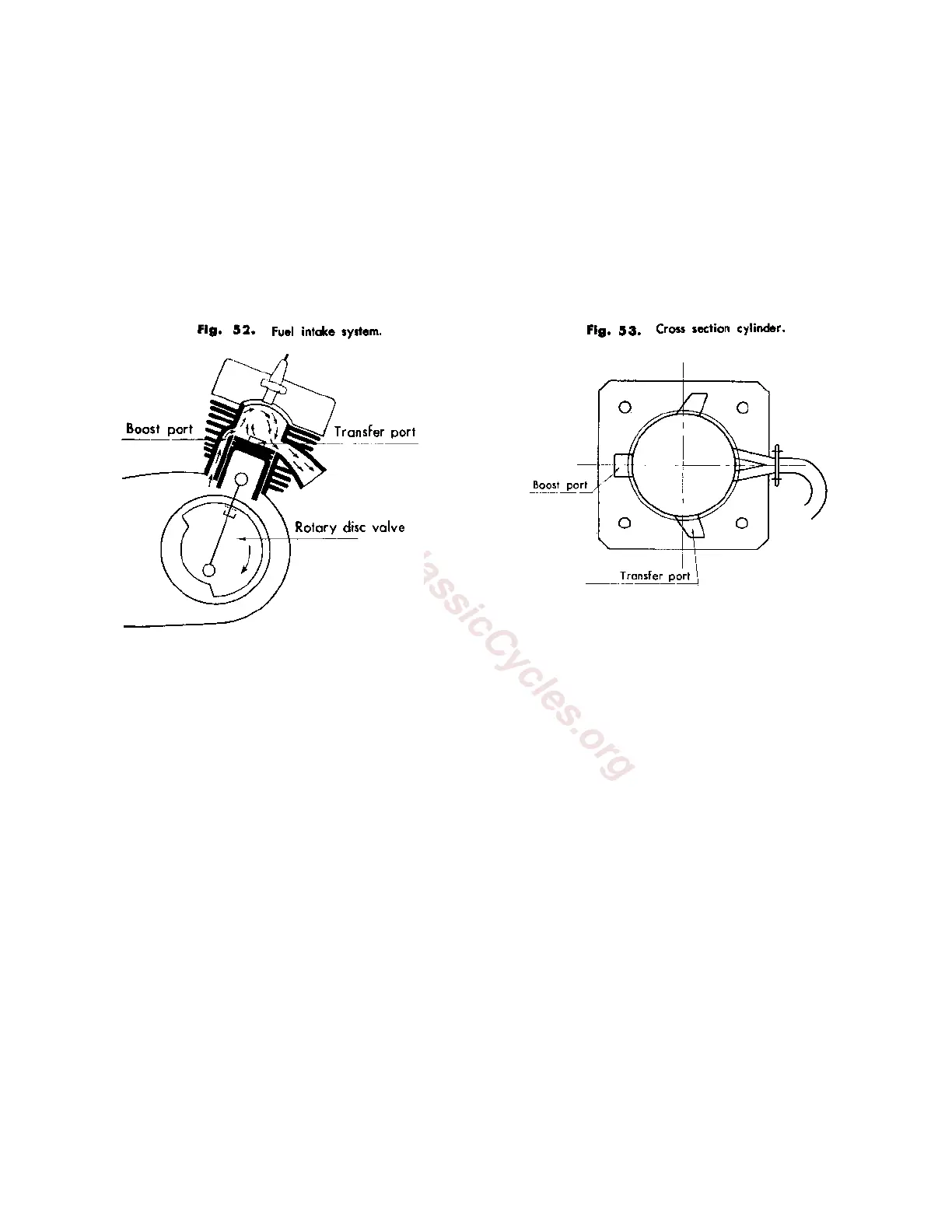

Because the carburetor is encased in the transmission case in the rotary disc valve engine, no intake port is

required in the cylinder. (The intake of fuel is controlled by the opening and closing of the rotary valve.)

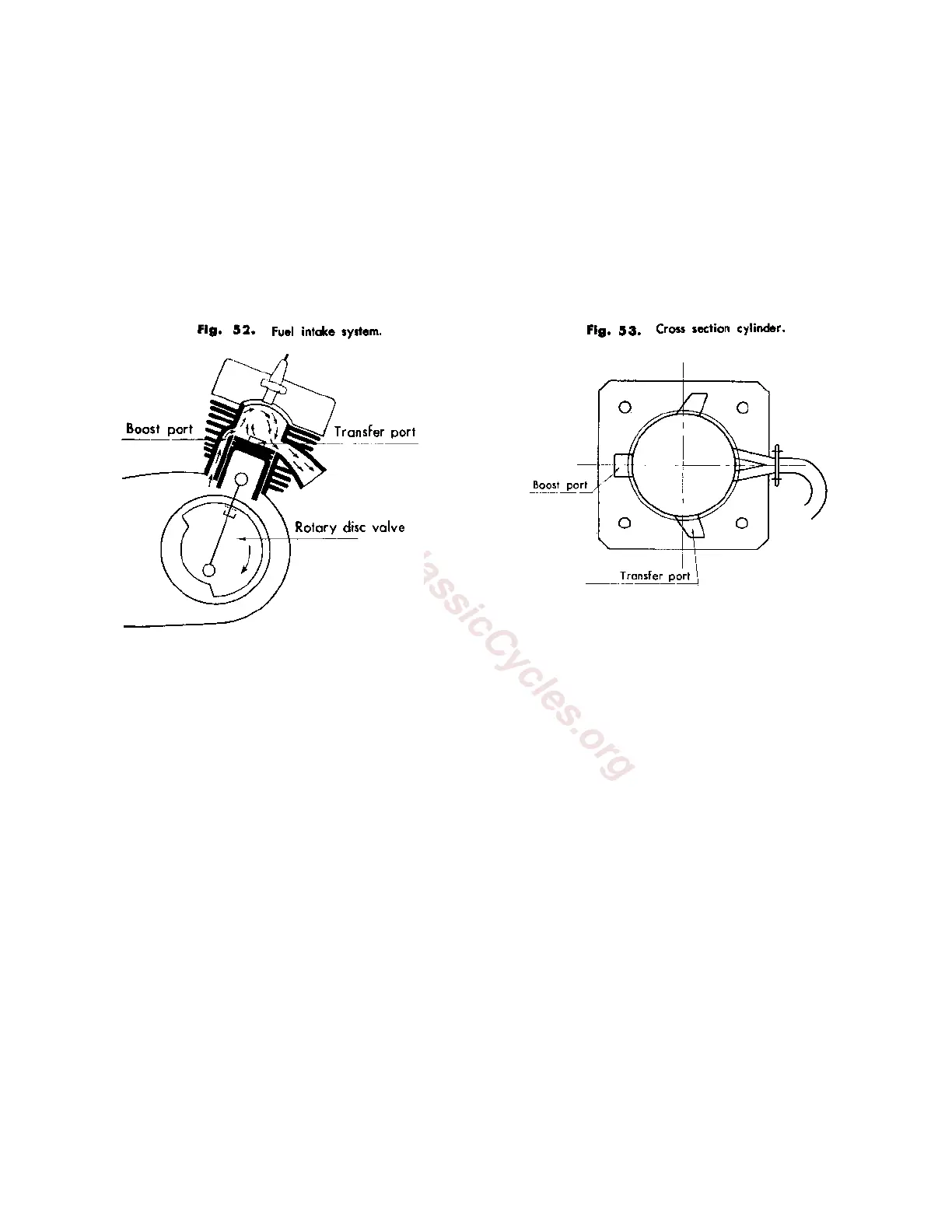

The exhaust port is located in the forward part and the transfer ports in the right and left sides and rear

part of the cylinder. The transfer port in the rear part of the cylinder is called the "boost" port. This booster

port expels exhaust gas and induces fresh fuel/air mixture into the combustion chamber, increasing

scavenging efficiency.

The pistons are aluminum alloy, made to resist wear and yet maintain excellent mechanical property at

high temperatures.

Pistons used in the cast iron cylinders are of high silicon aluminum alloy with a low coefficient expansion

and light specific gravity.

Those pistons used in the aluminum cylinders are of low silicon/alloy content, with a lower heat expansion

coefficient than the normal aluminum alloy pistons.

NOTE:

1. Pistons for the 90 STD, 90 T, 90 M could be used for replacement in the 90 Sport or 175 DT but only in

cases of emergency. (They are of a harder material and will wear the chrome faster.)

2. Pistons for the 90 Sport and 175 DT are not interchangeable and cannot be used in the cast iron

cylinders or the 90 STD, 90 T, 90 M. (They are of a softer material and will wear rapidly against cast

iron.)

3. The chrome plated ring used in the 90 STD, 90 T, 90 M cannot be used for the 90 Sport or 175 DT.

Chrome will not operate properly against chrome.

4. Pistons made only for cast iron cylinders can be recognized by the small center drilled hole in the top of

the piston.

Loading...

Loading...