50

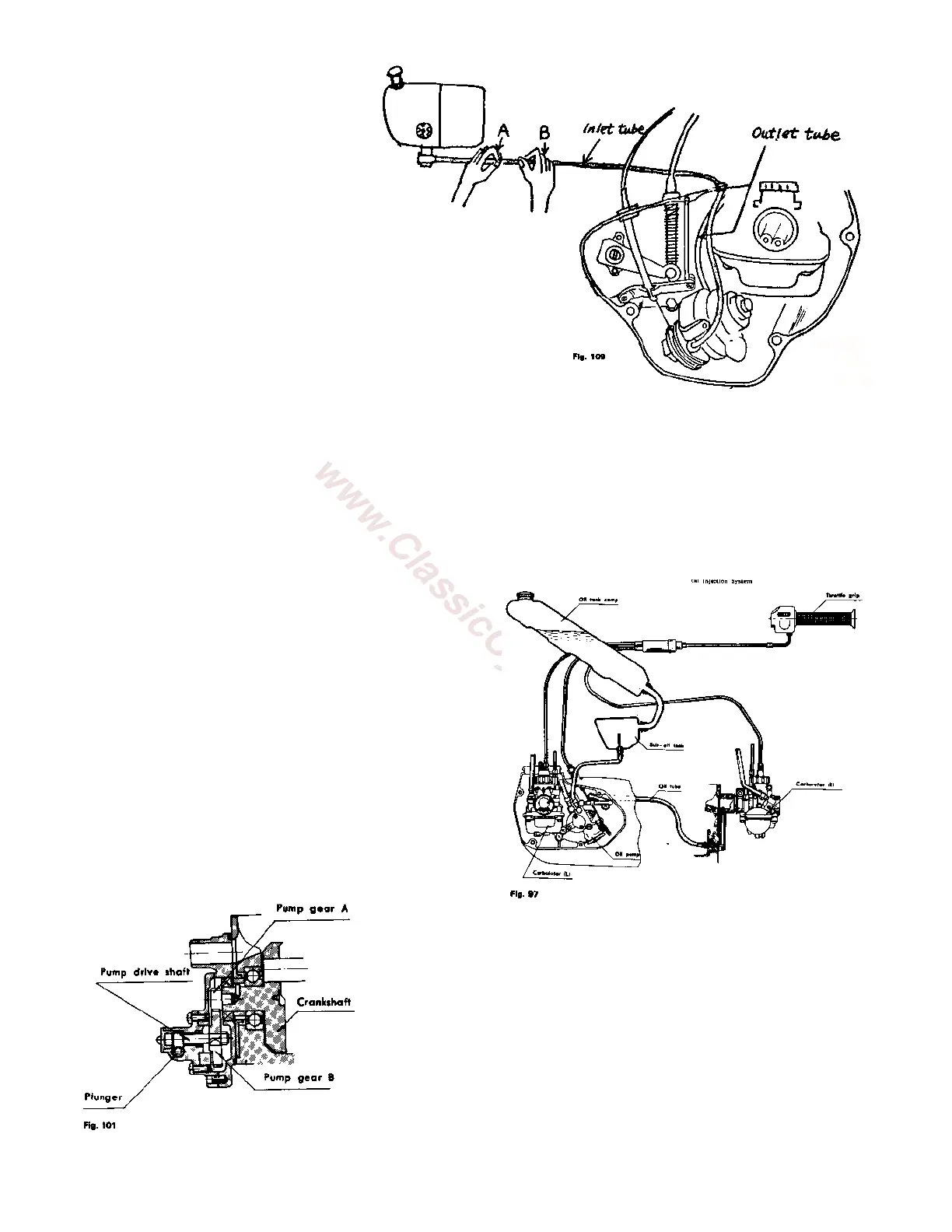

• NOTE: Pinch part A first, then

pinch part B; repeat alternately

until air bubbles are eliminated and

the oil flows freely out of the union

bolt.

5. Tighten the oil inlet union bolt and

repeat pinching with fingers; check

the oil flow in the outlet tube

(transparent) to the inlet in the

rotary valve cover.

• If there is no oil flow in the outlet

tube (transparent), repeat

procedure 4.

A simple check of the oil injection

system can prevent serious damage

when the machine is operated. Dirty or plugged oil lines, tanks, or filter could prevent the oil flow from the

oil tank to the pump.

Whenever a new cycle is serviced, the oil supply line to the pump should be removed at the pump and

checked for oil flow.

If a good supply of oil is not available at this line, check the tank, filter and lines and correct as necessary.

Oil must flow freely from this line to supply the engine with the proper lubrication.

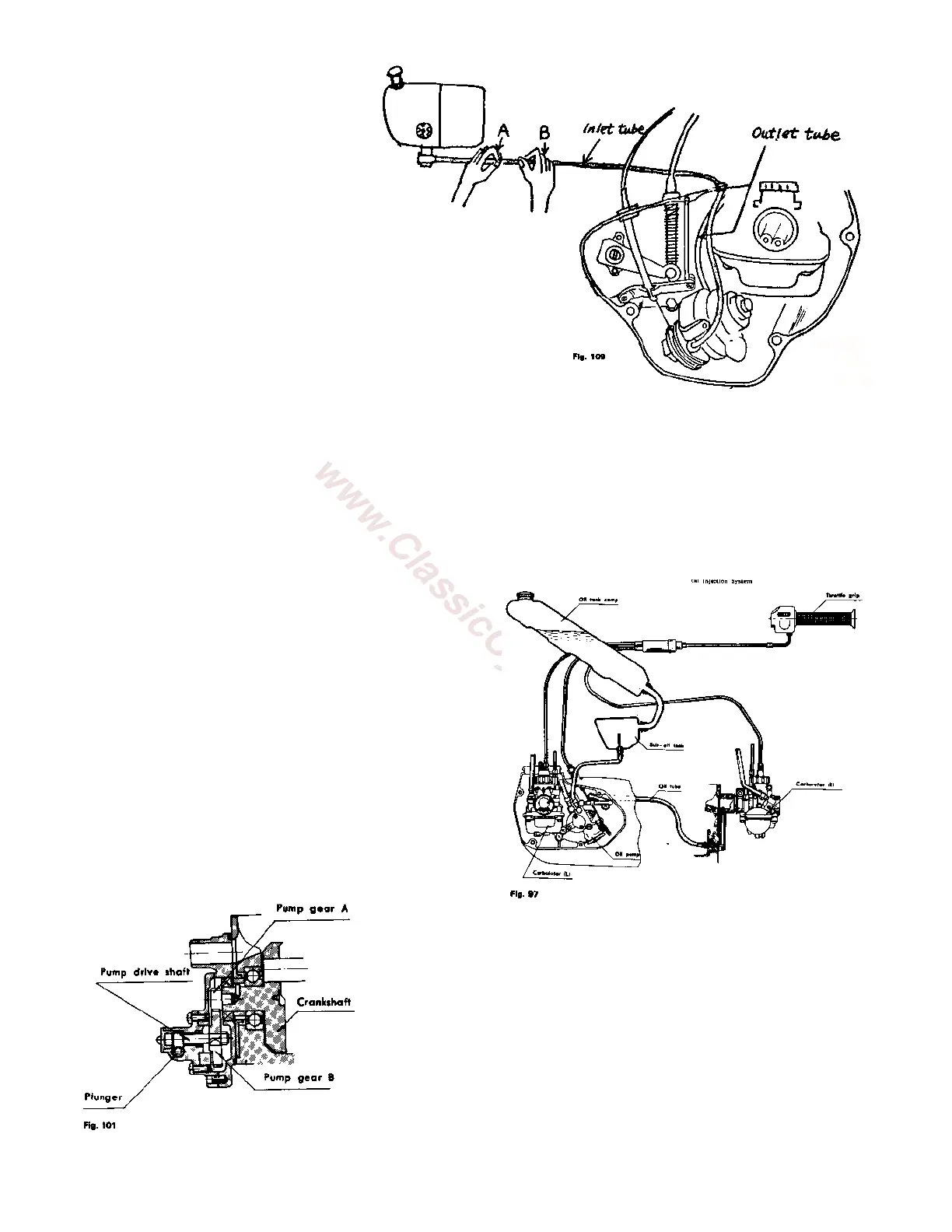

OIL INJECTION SYSTEM – 175DT

A. Construction and Operation:

Lubricating oil is supplied by an oil pump attached to

the left rotary valve cover. Oil pump gear B, attached to

the pump drive shaft, is driven by gear A, located on the

left end of the crankshaft.

The oil pump Drive Shaft drives the pump plunger

through a worm gear arrangement. The speed at which

the Plunger rotates, then, is determined by crankshaft

RPM. There is a 12:1 reduction in the gearing between

the crankshaft and the pump drive shaft.

In addition to being rotated by the pump drive shaft, the

Plunger moves up and down in the pump body. This

reciprocating

motion is produced by the cam-shaped lower end of the Plunger

bearing against the Plunger Guide.

The Plunger is held against the Plunger guide by the spring-loaded

Differential Plunger which bears against the top of the Plunger.

The length of the Plunger stroke is determined by the position of

the Stop cam in the lower end of the Pump Body. The stop cam is

part of the control arm assembly which is connected by means of a

control cable to the throttle grip.

Loading...

Loading...