44

Air which enters through the air jet mixes with the gasoline from the main jet in the needle jet and it is

atomized when mixed with the main air flow and flows into the engine.

(4) Float Chamber

The carburetor makes a proper gasoline/air mixture according to the throttle opening and engine speed. To

create this proper gasoline/air mixture, the supply of gasoline must remain constant. The float chamber

supplies a constant flow of gasoline to the carburetor.

Gasoline flows from the tank through the pipe to the carburetor banjo bolt and between the valve seat and

valve to enter the float chamber. When gasoline enters the float chamber, the float moves up to stay on top

of the gasoline and pushes the valve closed with the valve arm. When the valve touches the valve seat, the

flow of gasoline stops. When gasoline in the float chamber is consumed and the level lowers, the float moves

down and the float arm no longer presses against the valve, allowing it to move away from the valve seat

and gasoline to enter the float chamber between the valve and valve seat. These procedures are repeated

and a constant level of gasoline is kept in the float chamber.

B. Functions of Various Parts:

(1) Main Jet

The main jet controls the fuel supply when the throttle is more than

threequarters open, but at smaller throttle openings although the fuel passes

through the main jet the amount is diminished by the tapered needle jet.

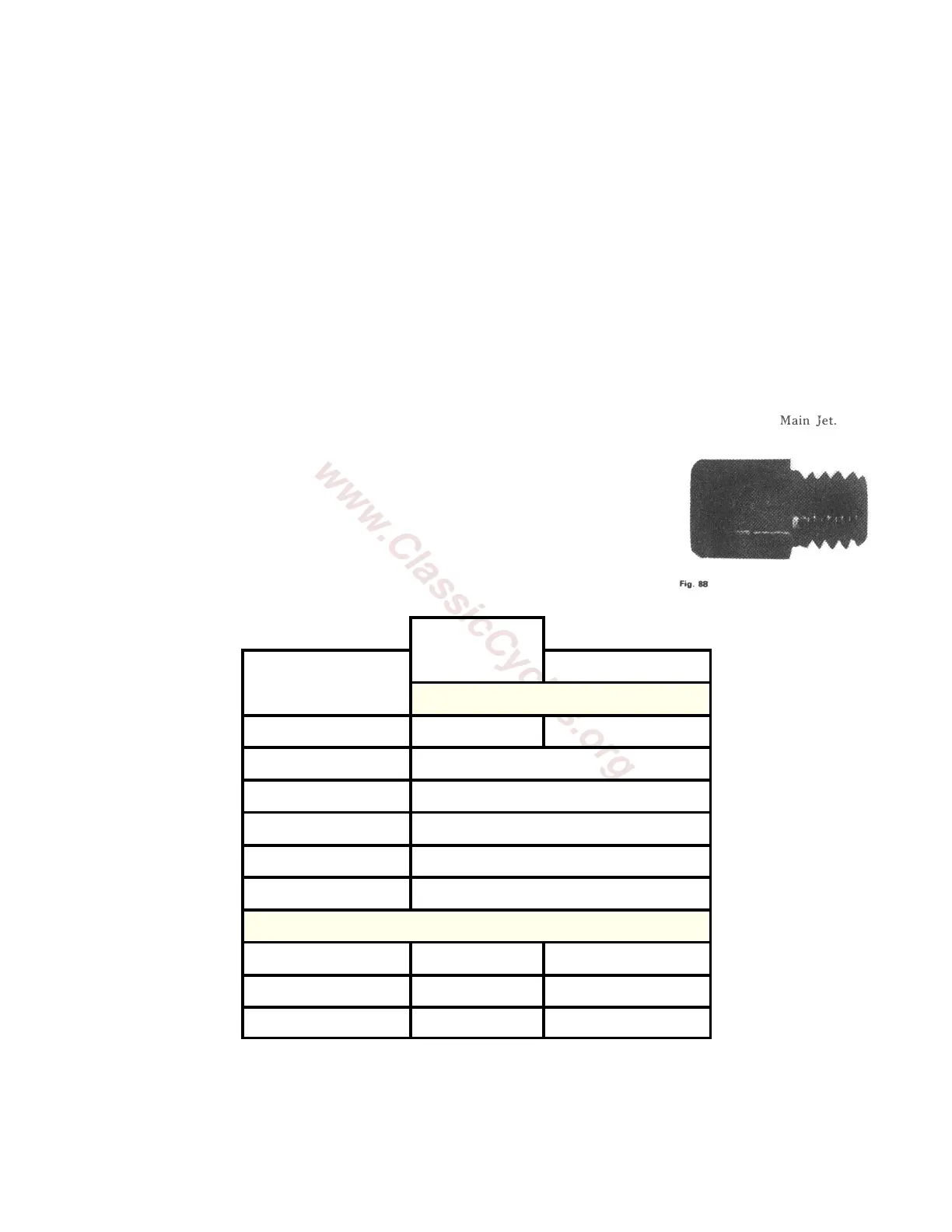

Listed below are the carburetor main jet sizes that are used as standard

equipment on the Bridgestone rotary valve models. Also listed are other sizes

that are available.

ORIGINAL

EQUIPMENT

MODEL

AVAILABLE

Main jet number

15mm Carburetor 110 100

56-60 Sport 100

90 before 12N 130

90 12N and after 120

90 Trail 130

90 Mountain 130

17mm Carburetor

90 Sp before 14L 95 Set of 5 (110-150)

90 Sp 14L and after 100 Set of 5 (110-150)

175DT 100 Set of 5 (110-150)

(2) Air Jet

Loading...

Loading...