Classic Cycles Technical Resources

63

3. Set charger for correct voltage (6V or 12V)

4. DO NOT LET FILLED, UNCHARGED BATTERY STAND LONGER THAN 12 HOURS BEFORE

CHARGING.

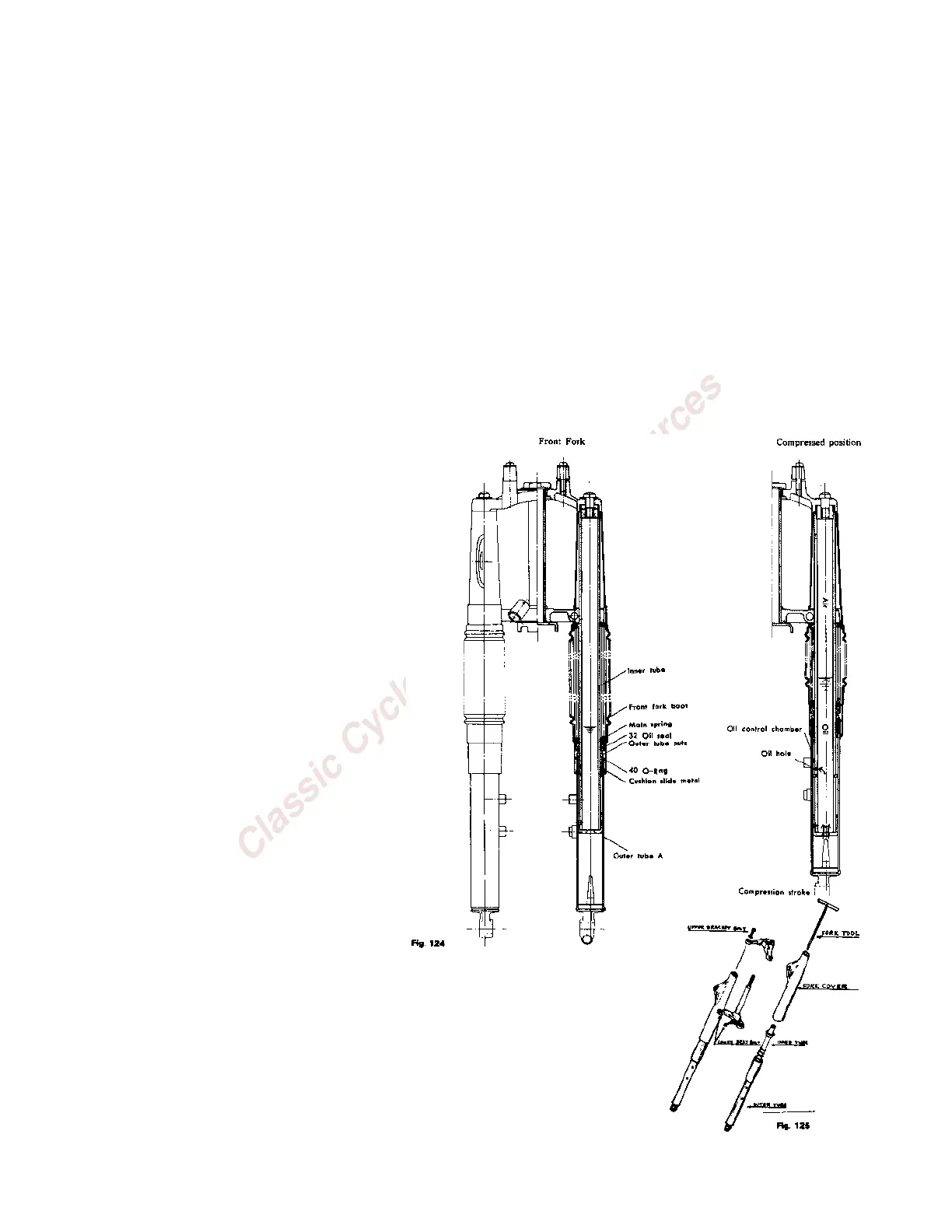

FRONT FORK:

Operation:

When a load is applied to the front fork, the load is received by the fork springs. At the same time, oil in the

oil chamber flows into the oil control chamber and the load is held by resistance of the compressed oil and

air and the shock is absorbed.

Oil lock bars are installed inside the bottom of the lower fork legs to prevent the fork from bottoming when

receiving severe shocks. When oil moves through the gap between the piston oil and the oil lock bar, shock

is absorbed by the resistance of the oil. The oil lock bar is tapered so that oil resistance increases as the

front fork shortens.

When the fork lengthens, rebound is dampened by oil resistance generated by the oil flow from the oil

control chamber through the oil hole to the oil chamber and by the oil flow through the gap between the oil

lock bar and the piston oil hole.

Maintenance:

If it is ever necessary to add fluid to the

front fork, use hydraulic jack oil. To insert

fluid into the fork, remove the upper

bridge bolt on the top of the fork tube. Do

not add more fluid than is required:

6 ozs. – 50, 60 Sport

6-7 ozs. – 90CC

7.5 ozs. – 175 DT

To determine the amount of fluid already

in the fork, remove the upper bridge bolt

on the top of the fork tube. Insert a wire

gauge of sufficient length, making certain

it touches the bottom of the tube. Remove

the gauge and measure the fluid mark. It

should measure 6 ½ to 7 inches (50, 60 Spt;

90) or 7 ½ to 8 inches (175 DT).

If no gauge is available, remove the screw

at the bottom of the outer tube and drain

the fluid. Reinsert the correct amount (in

ounces) for the particular model involved,

as indicated above.

NOTE: The front fork assemblies on the

B/S 50 Sport model with serial numbers before 13N are sealed units. For these

units the above instructions are not applicable. (Loss of fluid would require

replacement of the entire inner tube assembly. )

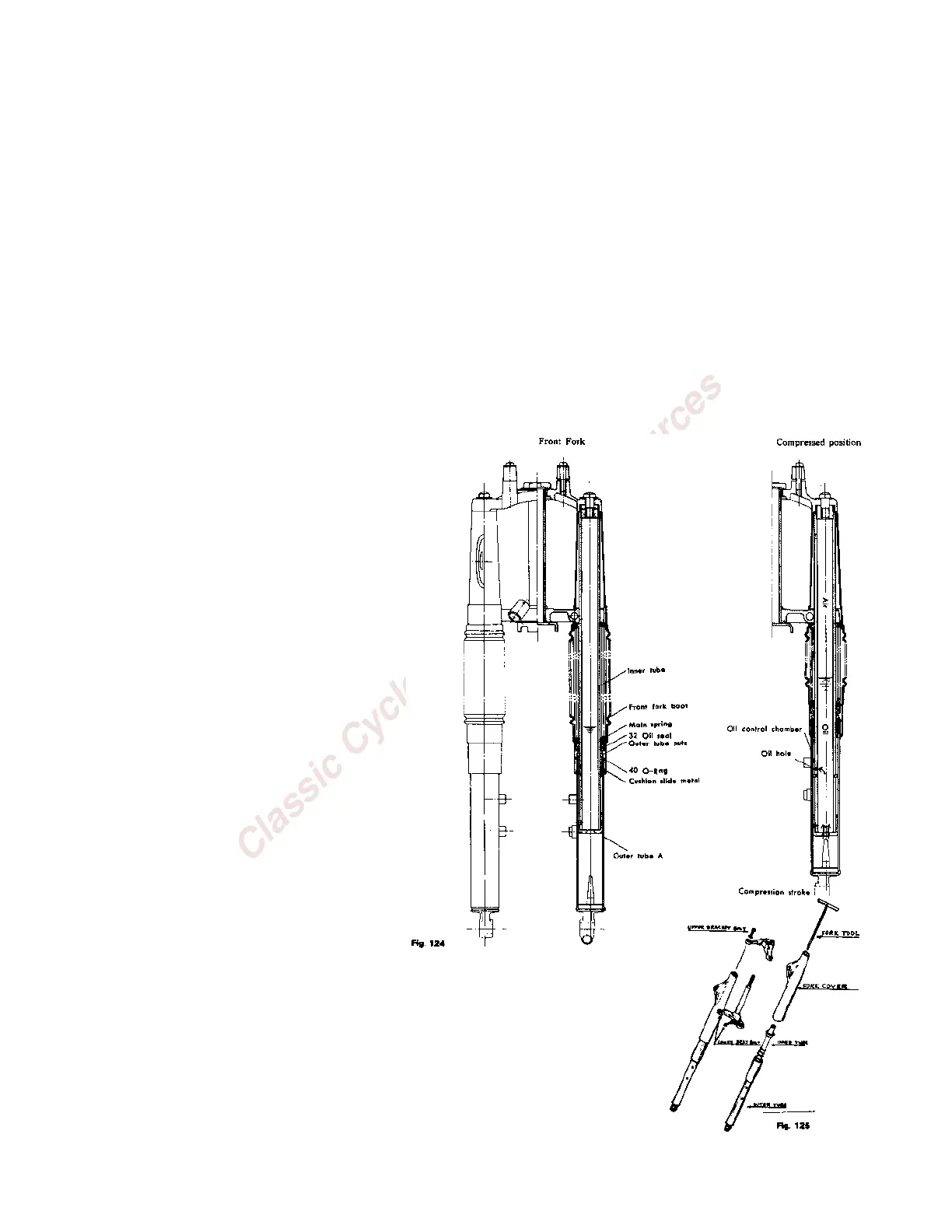

Assembling Front Fork:

CAUTION: When disassembling or assembling the front fork, do not tip inner

tube or outer tubes. This will avoid spilling the oil supply.

Loading...

Loading...