Classic Cycles Technical Resources

49

2. Assemble the gear case gasket and housing in place and reinstall 3 screws, fastening securely.

3. Place a small quantity of oil in the gear case housing and reassemble the pump onto the engine, but do

not install the mounting screws.

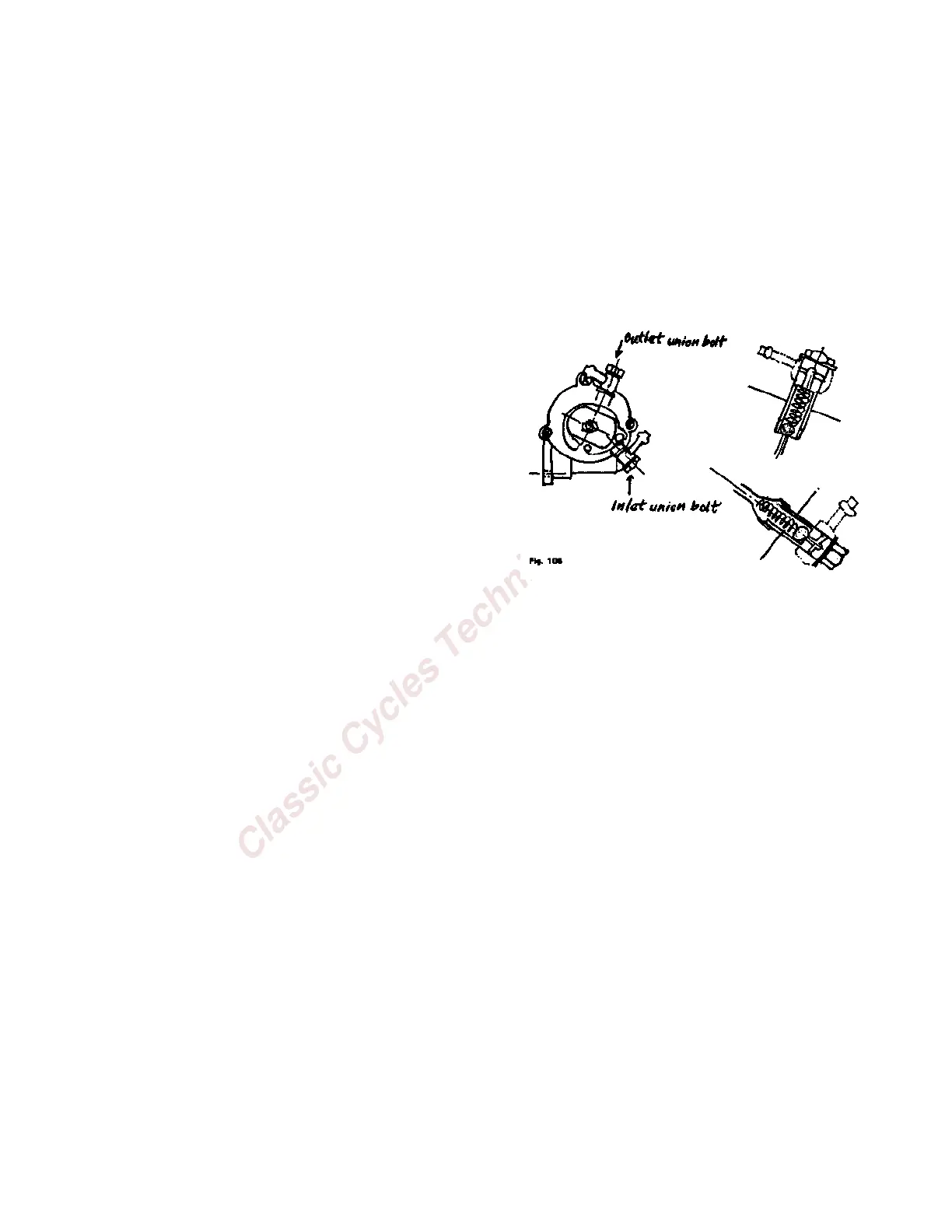

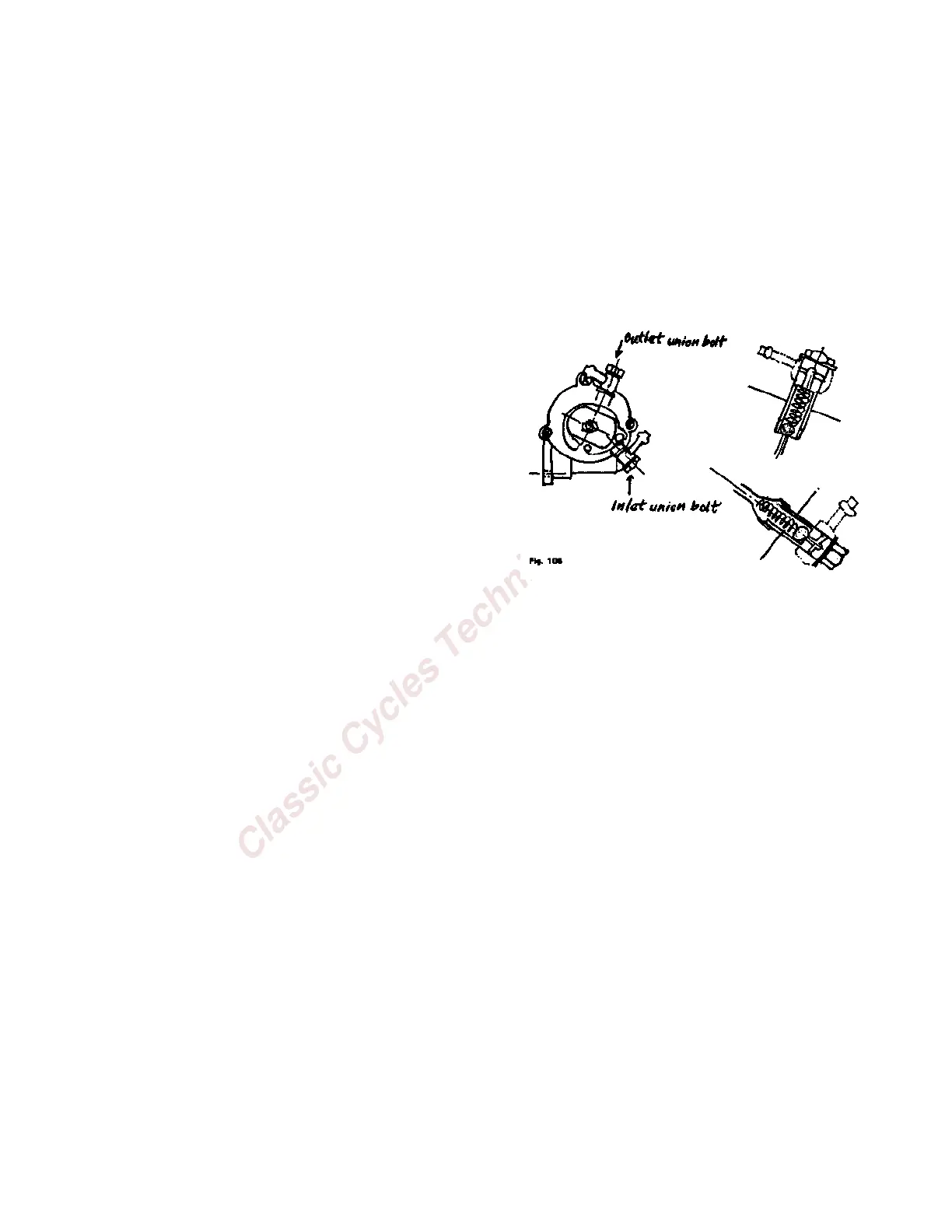

4. Reconnect the inlet and outlet oil lines.

(a) The brass connecting bolt and spring must be used on the inlet line.

• The spring must be installed first into the pump and then the check ball.

• NOTE: Only a brass connector bolt can be used in this port.

(b) The steel connecting bolt and spring must be used only on the outlet line.

• The check ball is installed first into the pump and then

the spring.

• NOTE: Only a steel connector bolt can be used in this

port.

5. When assembling the oil line onto the rotary valve

cover, a steel connector bolt must be used.

6. Do not over tighten the connecting bolts.

7. Install the 2 pump mounting screws and tighten

securely.

8. Connect the control cable to the pump and check its adjustment.

• With the throttle completely closed, the oil pump outer cable should have 1/16 of an inch of free play at

the oil pump cable stop pin. Adjustment is made by the cable adjuster located in the cable by the

transmission oil filter plug.

9. If, after adjusting the pump according to the above instructions, it appears that it is pumping too much

oil, without removing the pump, loosen lock nut "C" and turn the adjusting screw "D" clockwise a slight

amount. Never adjust more than c turn at a time until the cycle is operated and again check..

C. Special Attention to the Oil Injection System:

The following procedures are necessary after filling up the oil tank before break-in or after disassembling

oil tank or pump.

1. Remove the carburetor cover by screwing out the 4 carburetor cover screws.

2. The oil inlet tube (black) and the oil tube (transparent), which are connected to the oil pump, are shown

in Fig. 109

3. The oil outlet tube (transparent) is connected to the rotary valve cover.

• Procedures 4 and 5 are necessary to exhaust any air bubbles from the rotary valve cover, and obtain free

flow of oil from the pump to the outlet tube.

4. Loosen the oil inlet union bolt one or two turns, (do not take out this bolt) and pump oil out from the

union bolt on oil tube (black) connecting oil tank and oil pump, by pinching the oil tube alternately with

fingers of both hands as shown in Fig. 109

Loading...

Loading...