52

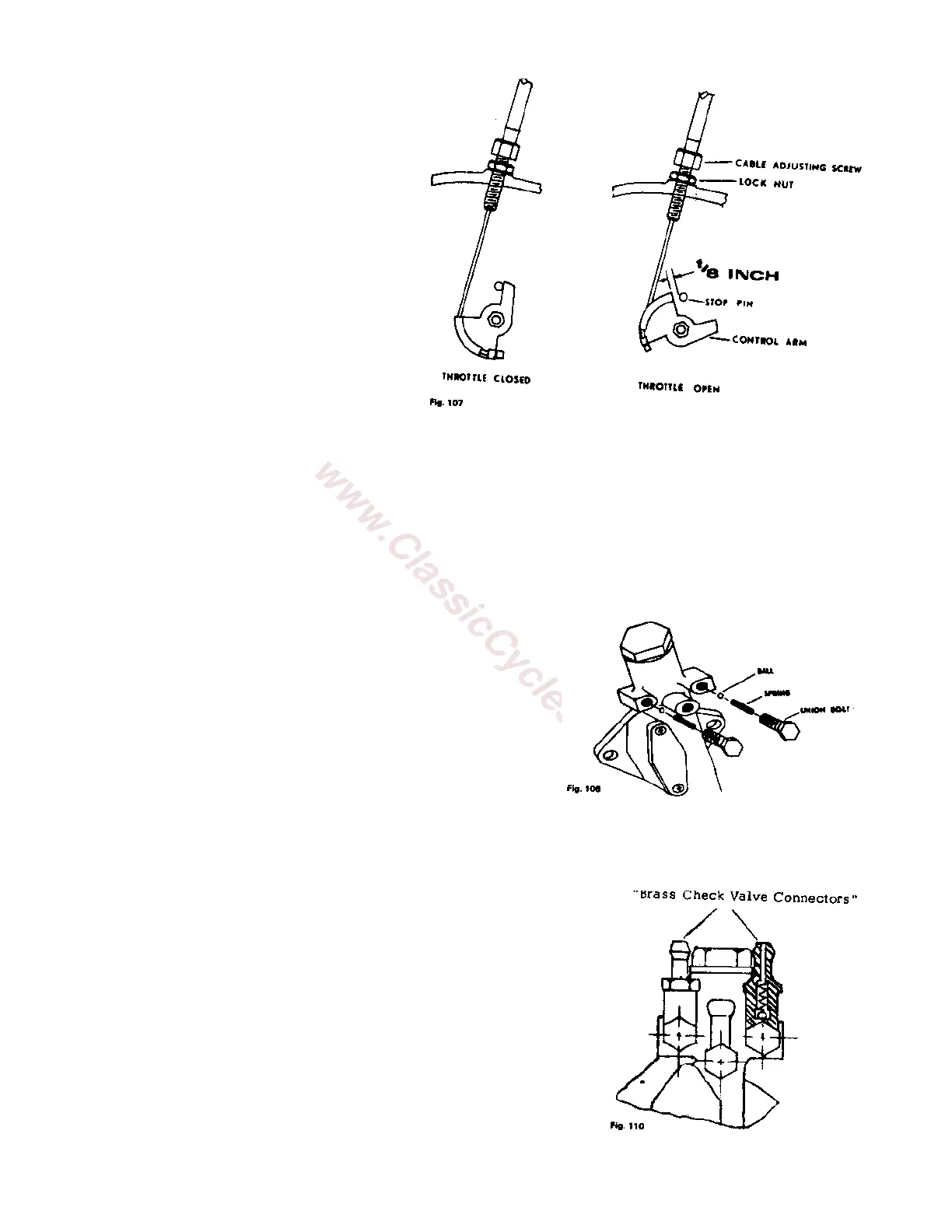

4. Cable adjustment is made at the cable

adjusting screw located above the left

carburetor housing, directly in front of the

generator. Loosen cable adjusting screw

lock nut and turn adjusting screw in for

additional stop clearance and out for less

until l/g inch of stop clearance is observed

with the throttle at maximum open

position.

NOTE:

1. Do not adjust to less than c inch

clearance.

2. When throttle is closed after adjustment,

the oil pump control arm may not return

to its closed position and may appear to be

faulty. However, the oil pressure in the

pump sometimes holds the control arm

open when it is operated without the engine running. This can be checked by running the engine or

operating the kick starter.

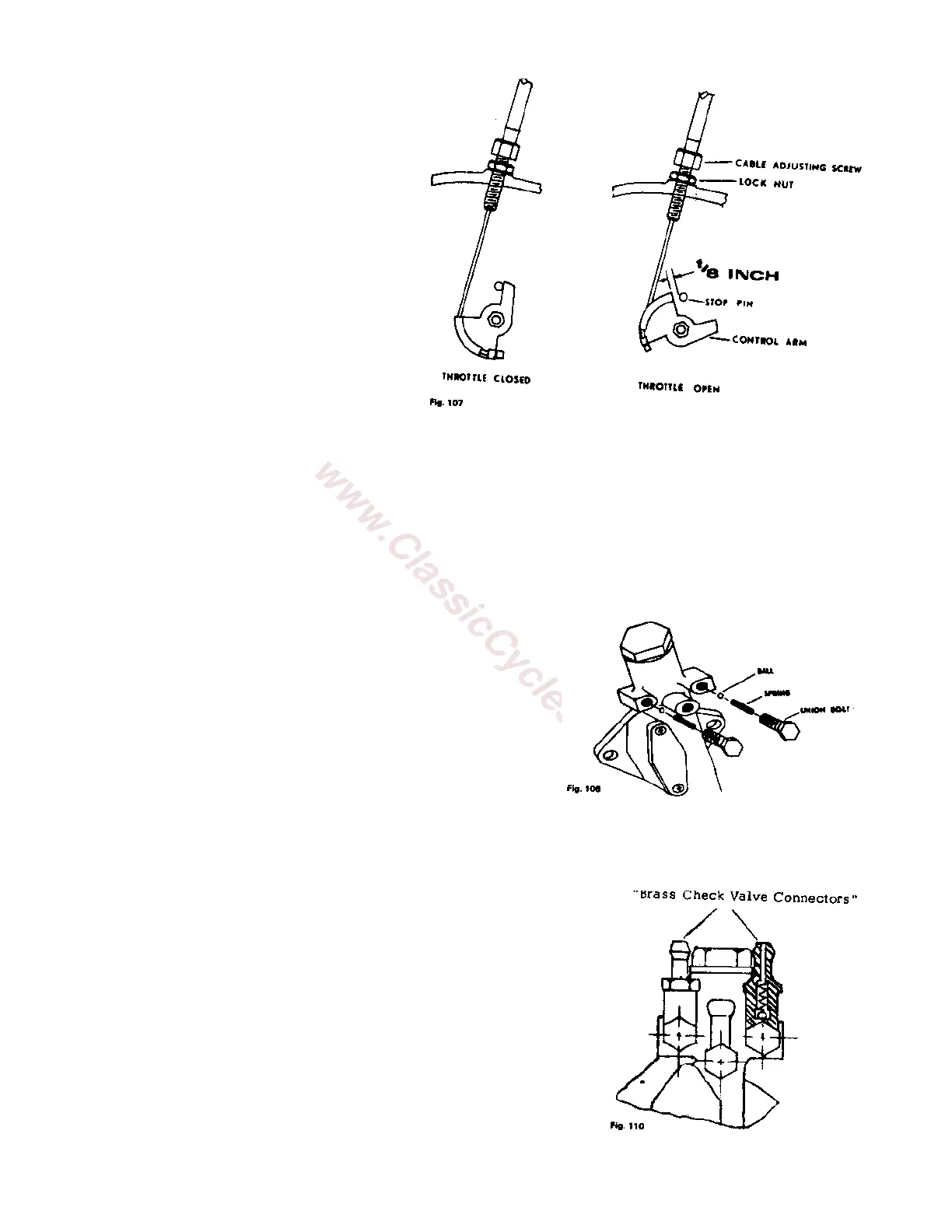

C. Special Attention — Pump Modification

Bridgestone 175 Dual-Twins manufactured after October, 1965, are equipped with a modified oil injection

pump. The new pump is equipped with ball and spring check valves in each of the pump body oil outlets.

The springs fit inside the union bolts which are unchanged from previous models.

DISMANTLING OIL PUMP

1. Ball check valves are installed only in the outlet ports (Never

in the inlet port.)

2. Ball check valves cannot be installed in the old style pumps

that were not originally equipped with them.

3. When assembling the unit, first install the ball in the outlet

port hole. Next, install the spring into the union bolt. Then

with the oil line connector and picking washers installed on

the bolt, screw the bolt into the outlet port hole.

4. The style of oil pump can be determined by viewing into the outlet port holes. The outlets on the old style

pumps have no ball valve seats machined in them and the check

ball will pass through the outlet, into the oil pump body.

• The new style pumps have check ball valve seats machined in the

outlet ports.

5. New style oil pump assemblies are interchangeable with the old

style assembly. An additional change was made in Feb., 1966,

Serial No. 16B. This change incorporates the ball and spring check

valves into a new style outlet connector.

The ball and spring are assembled inside of the new connector and

eliminate the possibility of incorrect assembly or loss of these parts.

Loading...

Loading...