Classic Cycles Technical Resources

55

KEY TO USE CODE:

A Standard plug for break-in and normal use.

B Hotter plug for low speed use and when standard plug fouls easily.

C Colder plug for high speed use and when standard plug burns easily.

D Cold plug. Standard for competition use.

E Extremely cold plug for high speed racing. Will operate well only at extremely high temperatures. Starting may be difficult with

this plug. Not recommended for normal use.

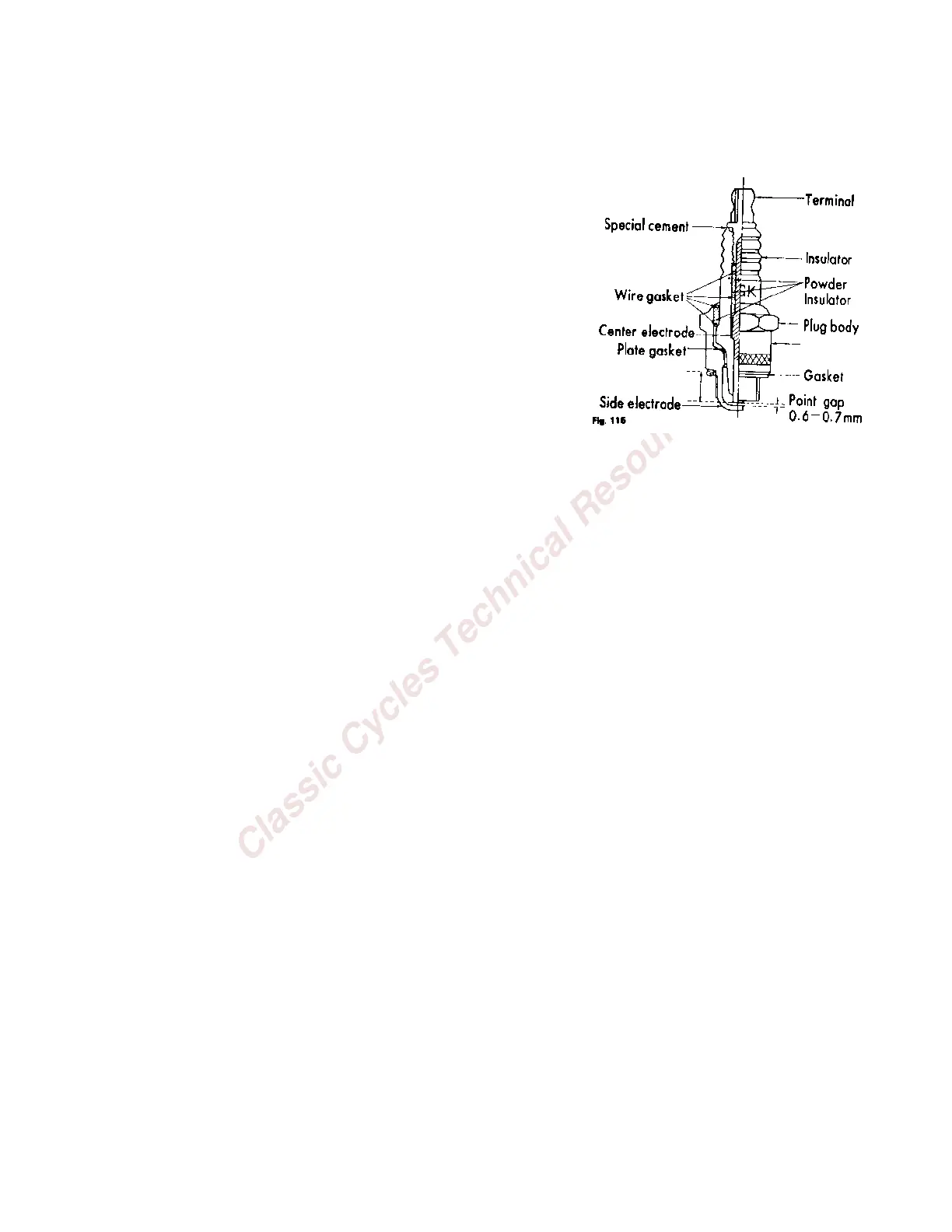

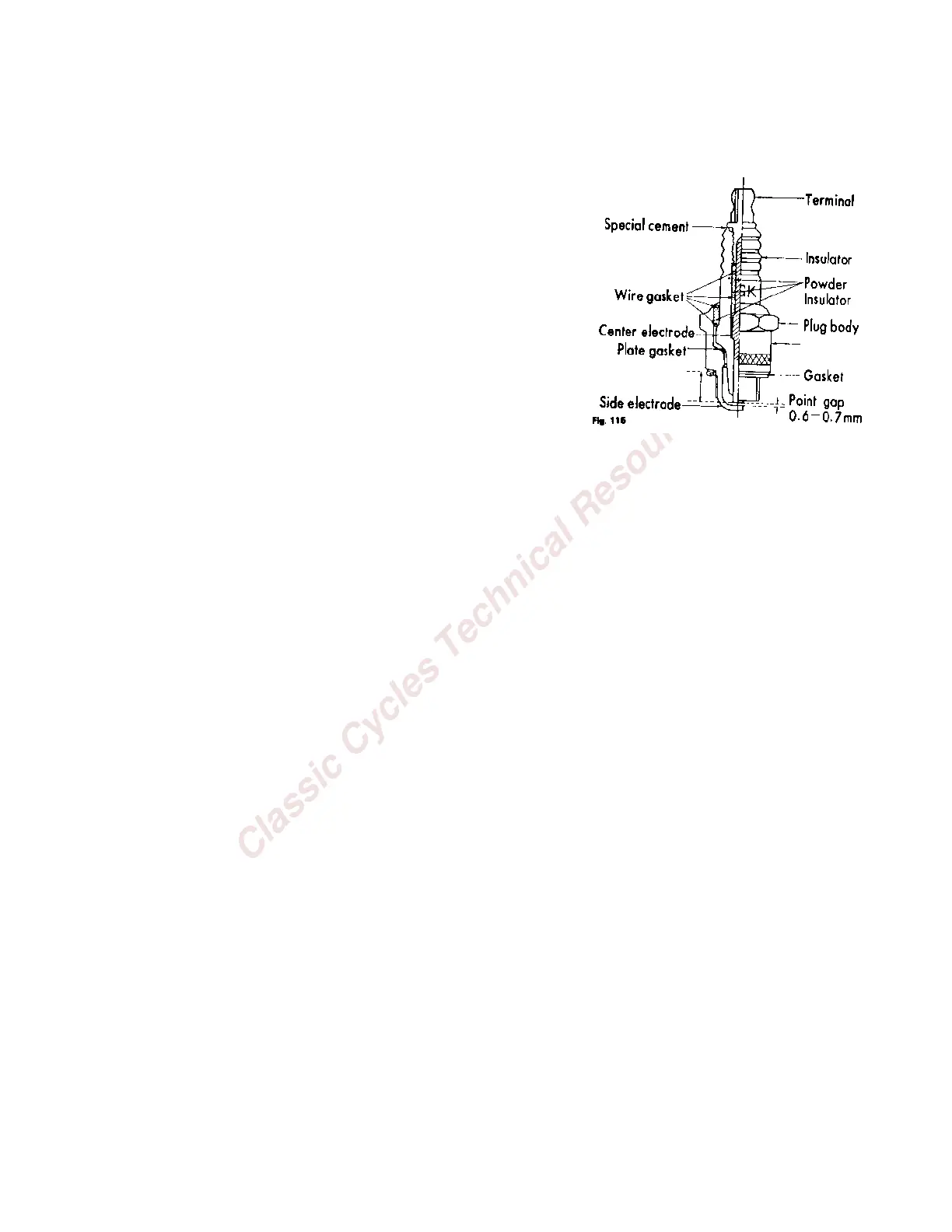

Correct gap on all plugs is between .024 – .027". The spark plug

should be checked at least every 2,000 miles. A worn or dirty plug

produces weak spark and causes hard starting, low power output,

irregular rpm and damage to the ignition coil.

The spark plug should be checked and cleaned periodically with a

stiff wire brush and gasoline or other cleaning solvent. The use of

an abrasive in cleaning the spark plug is not recommended since

abrasive particles may be introduced into the combustion chamber

and result in cylinder damage.

B. Testing the Ignition Coil:

The ignition coil can be tested efficiently by connecting the spark

plug cap to one lead of a gap tester. Ground the other lead of the tester and kick the kick starter. A spark

should jump the quarter-inch ( ¼ ) gap. If the spark does not jump this gap, suspect that the ignition coil is

defective. Points, condenser, and timing should be checked, however, before replacing the ignition coil.

C. Technical Standards: The technical standards of electrical components are indicated below:

MODELS

DESCRIPTION SPECIFICATIONS 50, 60 Spt 90cc

Condenser Capacity in Microfarads — 0.25 to 0.30

mfd

X X

Ignition Coil

(Primary)

Operating Voltage — 0.5 volt X X

Operating Amperage — 1.5 to 2.5 amps X X

Ignition Coil Primary Continuity — 1.5 to 2.0 ohms X X

Secondary Continuity — 8000 to 9000

ohms

X X

Lighting Coil Continuity — Yellow wire to ground

0.2 ohms X

0.5 ohms X

Continuity — White wire to ground

0.1 ohms X

0.5 ohms X

NOTE: Refer to Troubleshooting section for proper testing procedures in checking generator and charging

system on B/S 175 DT.

D. Lighting System:

The magneto armature plate also contains a lighting coil. (Fig. 111) The lighting coil provides current to the

headlight and taillight. It also provides AC current to the selenium rectifier which converts this current to

DC to "trickle" charge the battery. The battery is a 6 volt-4ampere hour battery furnishing current to the

brake light and the neutral gear indicator light. The battery also functions as a stabilizer in the electrical

circuit. At high speeds, the magneto puts out from 12 to 18 volts. This current passes through the battery

which stabilizes it at 6 volts. It is important that the battery is fully charged at all times since a discharged

battery will not offer sufficient resistance in the electrical circuit. When battery charge is low, the headlight

and taillight bulbs will be burned out instantly when they are turned on.

Loading...

Loading...