Polycold Cryochiller Specifications and Site Preparation

Installation and Operation Manual Cooling Water

Brooks Automation

214072 Revision B

3-7

Cooling Water Purity

The chemistry of water typically used to cool equipment can vary widely. Multiple different elements,

compounds and ions may be present at the same time. Depending on which chemicals are present,

their amount, and the cooling water temperature, there may or may not be a risk for scaling.

The guidelines listed here are provided to reduce the potential for scale and scale related corrosion.

Whereas scale reduces heat exchanger effectiveness and cause the cryochiller performance to

degrade, scale deposits can result in corrosion that can occur beneath the scale layer. The presence

of excessive amounts of chlorine or chloride can accelerate this type of corrosion.

In addition to scale, the accumulation of micro organisms on heat exchanger surfaces can lead to

corrosion. Even after microbes have been killed by heat of chemical agents, they remain on the

surface and have the same effect as scale.

The specific elements of water quality which are important depend upon your local area and the

minerals and chemicals dissolved in your cooling water. Although your local water supply was used to

fill water into your cooling loop, it is the chemistry of the water circulating through your cooling loop

which is important. In many cases, this is significantly different from the make up of the water originally

filled into the cooling loop.

Best practice for cooling loop maintenance call for periodic sampling (i.e. monthly) and analysis of the

water quality circulating in the cooling loop. When parameters are beyond the limits listed in Table 3-7,

then corrective action is needed to bring them within the limits.

In cases where the cooling water is consistently at risk for scale, a periodic descaling process should

be put in place, such as monthly or quarterly depending on scaling risk. Scale risk typically increases

with water outlet temperature. This risk increases significantly when the compressor is allowed to

operate without any water flow. While such events are expected, if a unit is repeatedly operated

without cooling water, the condenser should be descaled.

Water quality may vary by location. The most common chemical properties and their recommended lev-

els are identified in bold in Table 3-7. Additional properties which may be present in your cooling water

are listed without bold.

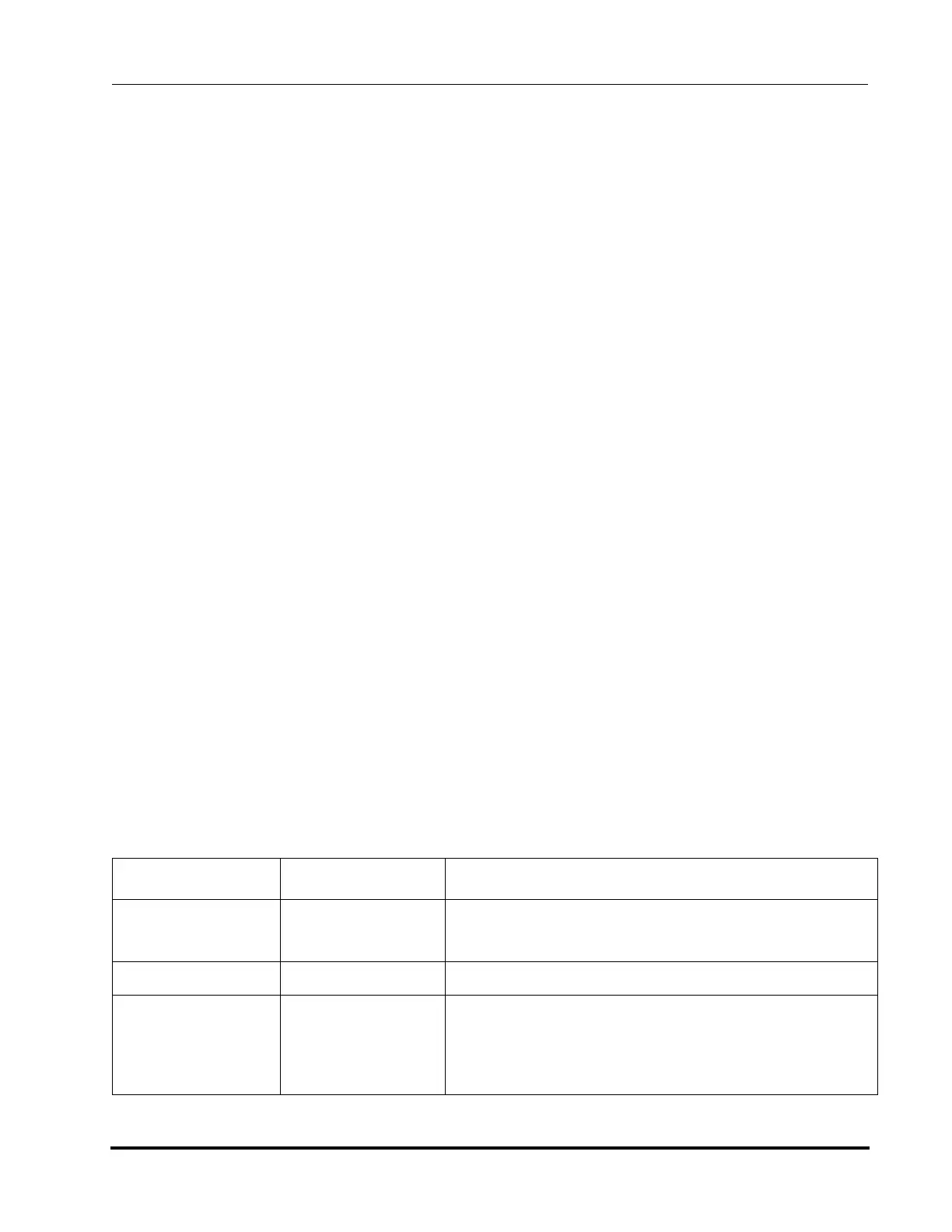

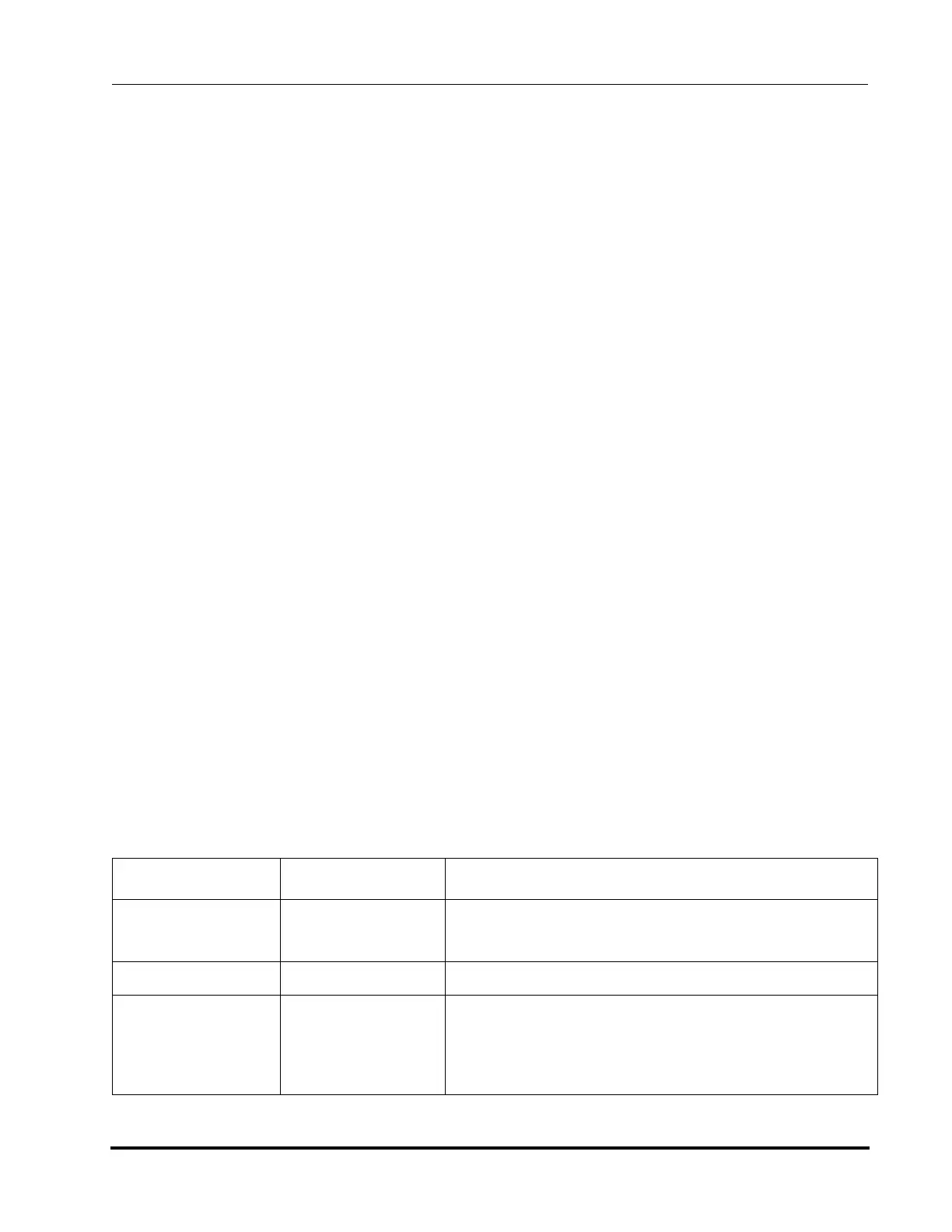

Water Purity Properties

The following table provides general water purity guidelines.

Table 3-7: Water Purity Properties

Water

Property

Recommended

Level

Explanation

Microbiological

Control

<10,000 CFU

(Colony Forming

Units)

Higher microbiological levels can result in buildup of

biofilm, which causes poor heat transfer and copper

pitting corrosion.

Particle Size < 100 microns Larger particles can clog heat exchanger passages.

pH 7.5 - 9.0

Lower levels increase corrosion risk

Higher levels increase scale formation and precipitation.

Some references recommend keeping the pH level in the

range 7.5 – 8.5

Loading...

Loading...