Installation Polycold Cryochiller

Check the Refrigerant Line and Cryosurface for Leaks Installation and Operation Manual

Brooks Automation

4-28 214072 Revision B

sure. This is important to assure that helium does not migrate into and contaminate the refrigerant sys-

tem. When the system is off, the lowest pressure is the balance pressure.

During evacuation of the line and coil, after the leak check, it is recommended to purge the line with dry

nitrogen or dry argon that has a dew point of -80 C or less since it can be difficult to pump out pure

helium.

Be aware of false positives created by the armaflex insulation around the line set. The factory installed

tube insulation and flat insulation can produce false positives with some leak check sensors.

Leak Check Procedure

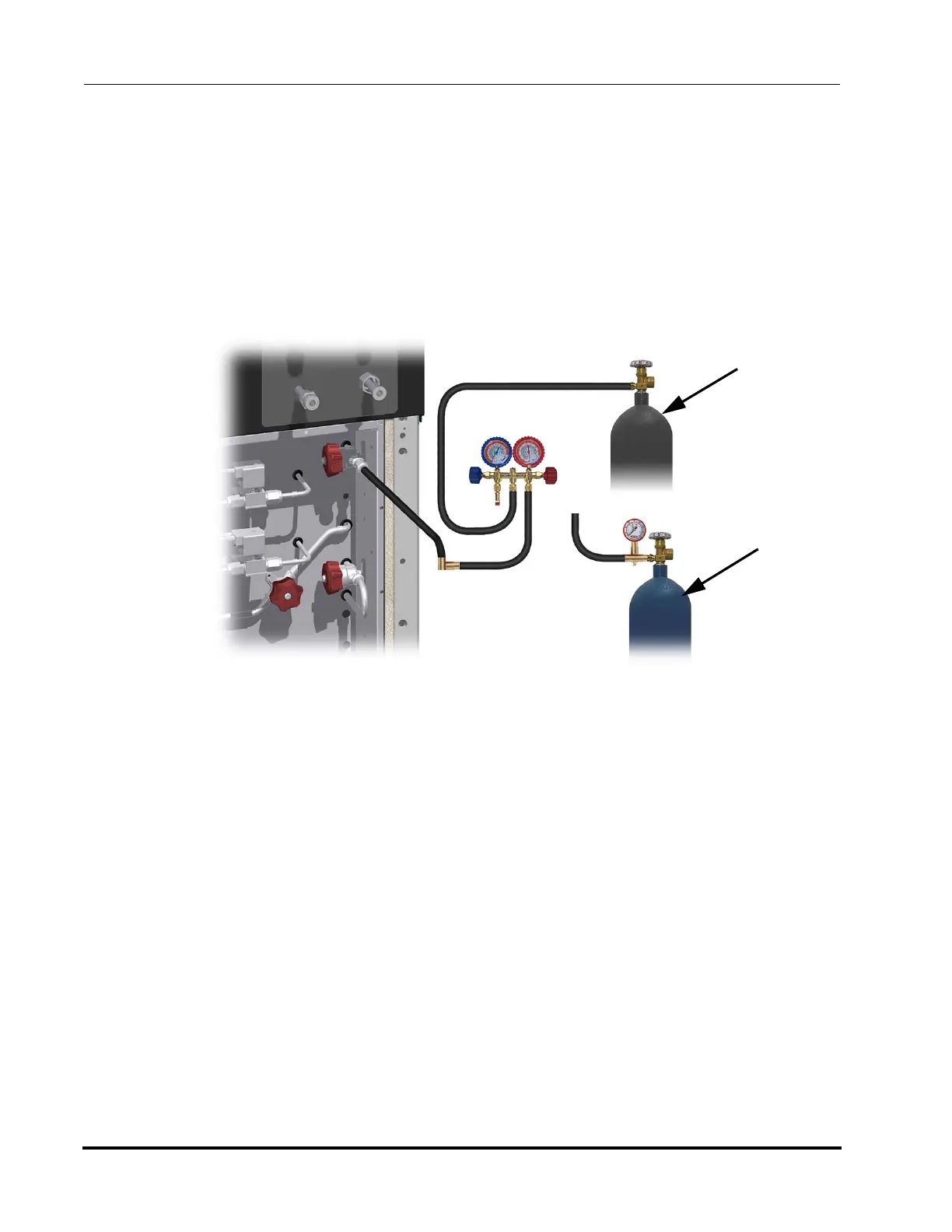

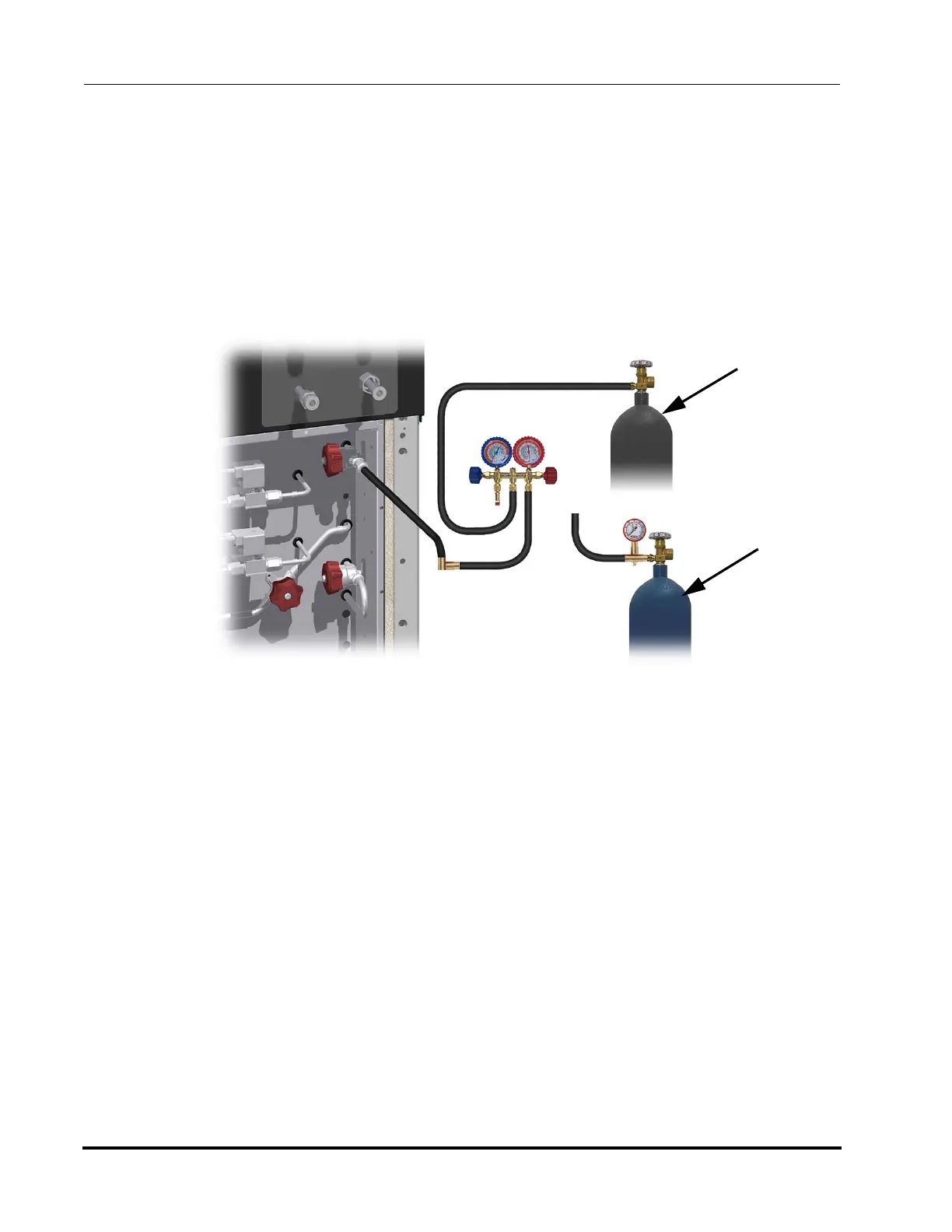

Refer to Figure 4-21 and Figure 4-22 for the following steps.

1. Make certain the valves on the manifold are closed.

2. Connect the manifold's suction (low pressure) hose to the evacuation valve inside the valve box.

See Figure 4-21.

3. Open the evacuation valve.

4. Connect the refrigerant cylinder to the center port of the manifold.

5. Open the suction valve on the manifold and pressurize the refrigerant line and cryosurface to

70-140 kPa (10-20 psig). This adds refrigerant trace gas to the system.

Figure 4-21: Leak Check - Add “Trace” Refrigerant

Refrigerant

Gas

R134a

Dry

Nitrogen

Gas

Loading...

Loading...