Installation Polycold Cryochiller

Install the Refrigerant Lines Installation and Operation Manual

Brooks Automation

4-20 214072 Revision B

Guidelines for Refrigerant Lines

• Improper connection of the couplings is a common source of leaks. Internal leaks can damage

the equipment.

• Use a new O-ring or gasket each time the coupling is assembled.

• Do not use grease when assembling the couplings. Grease can contaminate the cryopump and

can mask a leak during the leak-checking procedures. Additionally, the coupling will leak when

the grease gets brittle at cryogenic temperatures.

• Do not scratch or dent the sealing surfaces of the couplings.

• Always use the O-ring removal tool to remove an O-ring from the Parker UltraSeal compatible

couplings. See Appendix G: Zero Line Loss Procedure on page 12-13.

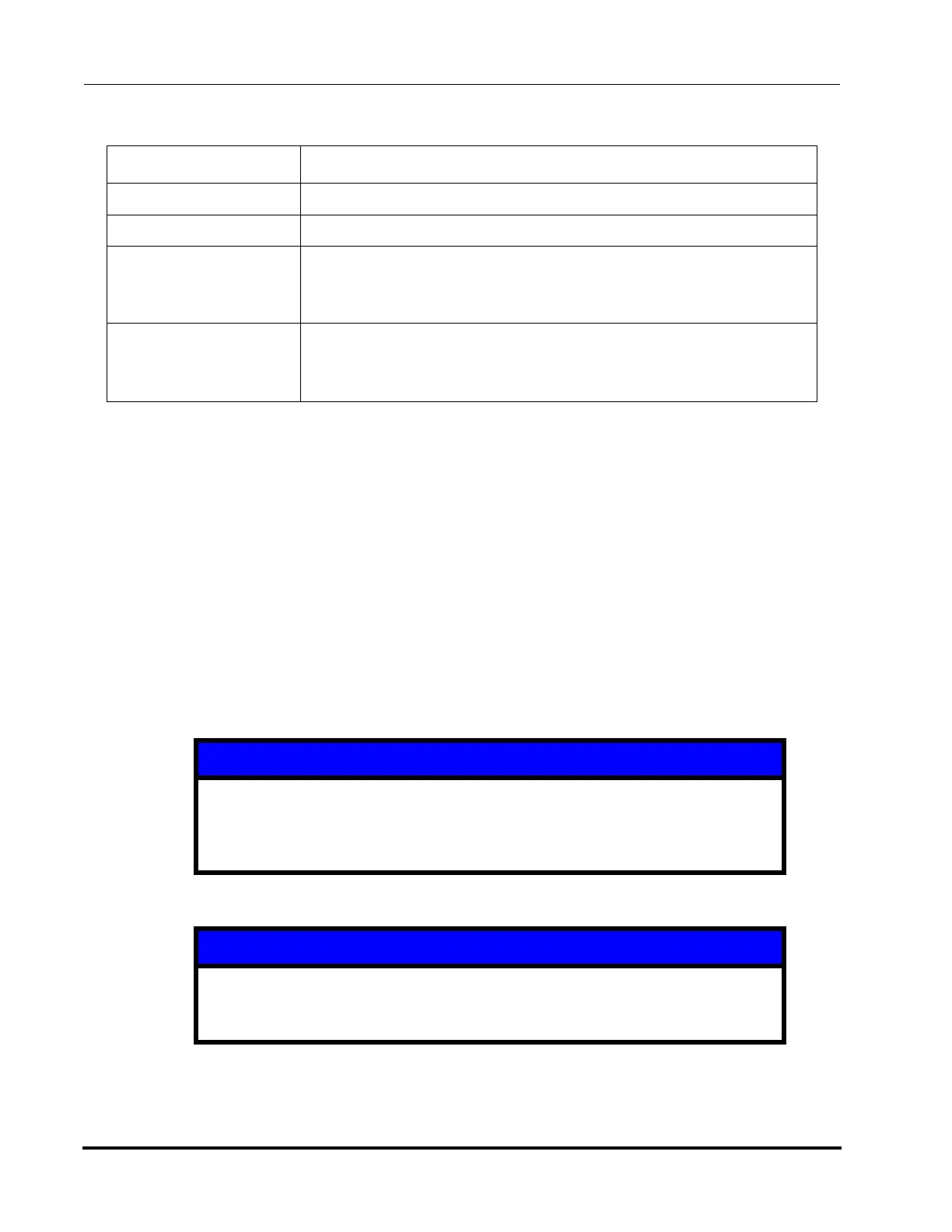

Item Description

Electrical Category Type 1 – Equipment is fully de-energized

Tools Torque wrench (optional)

For Parker UltraSeal

Style Couplings

(Standard)

Silver-plated stainless steel O-rings

1 inch open end wrench

15/16 inch open end wrench

For Cajon VCR

Style Couplings

(Optional)

Silver-plated stainless steel gaskets or unplated nickel gaskets

1-3/16 inch open end wrench

1-1/16 inch open end wrench

NOTICE

Use of unauthorized or non-standard couplings voids your warranty.

Improper use of, incorrect installation of, over-tightening of, or use of damaged

O-rings in couplings will void your warranty.

NOTICE

O-ring removal tool requires lubrication.

Always clean couplings after using the lubricated tool.

Loading...

Loading...