Do you have a question about the Bruker D8 Series and is the answer not in the manual?

Details three performance verification levels for instrument functionality.

Test performed at manufacturer's site to guarantee initial performance.

Test performed at customer's site after delivery/installation.

Routine procedure to check instrument operation within specified limits.

Guidance on performance verification for GxP regulated areas.

Details on the certified reference material for instrument verification.

Instrument parameters for Bragg-Brentano and parallel beam systems.

Measurement parameters for Cu and Co radiation.

Methods for evaluating measurement data and interpreting results.

Evaluation steps for instruments with a primary beam monochromator.

Evaluation steps for instruments without a primary beam monochromator.

Reference values for peak positions and relative intensities for Corundum sample.

Setting reference positions for basic Bragg-Brentano setups.

Setting deflection angles for parallel beam and TWIN/TRIO optics.

Protocol for factory and customer acceptance testing.

Maximum allowed values for line shape (FWHM) for Cu-radiation.

List of referenced documents and their corresponding document numbers.

Definitions of key terms used in the manual.

List of appendices covering test protocols and daily checks.

Statement confirming the system meets required specifications.

Protocol details for factory acceptance test of Bragg-Brentano with Cu anode.

Details of instrument configuration for D8 ADVANCE in Factory Acceptance Test.

Evaluation of angular accuracy, instrument response and resolution.

Statement confirming the system meets required specifications.

Protocol details for factory acceptance test of Bragg-Brentano with Co anode.

Details of instrument configuration for D8 ADVANCE in Factory Acceptance Test.

Evaluation of angular accuracy, response and resolution for Co anode.

Statement confirming the system meets required specifications.

Protocol details for factory acceptance test of Parallel Beam with Cu anode.

Details of instrument configuration for D8 ADVANCE in Parallel Beam Geometry.

Evaluation of angular accuracy and resolution for Parallel Beam Geometry.

Statement confirming the system meets required specifications.

Protocol details for factory acceptance test of Parallel Beam with Co anode.

Details of instrument configuration for D8 ADVANCE in Parallel Beam Geometry.

Evaluation of angular accuracy and resolution for Parallel Beam Geometry with Co anode.

Statement confirming the system meets required specifications.

Protocol details for customer acceptance test of Bragg-Brentano with Cu anode.

Details of instrument configuration for D8 ADVANCE in Customer Acceptance Test.

Evaluation of angular accuracy, response and resolution for Customer Acceptance Test.

Statement confirming the system meets required specifications.

Protocol details for customer acceptance test of Bragg-Brentano with Co anode.

Details of instrument configuration for D8 ADVANCE in Customer Acceptance Test.

Evaluation of angular accuracy, response and resolution for Customer Acceptance Test with Co anode.

Statement confirming the system meets required specifications.

Protocol details for customer acceptance test of Parallel Beam with Cu anode.

Details of instrument configuration for D8 ADVANCE in Customer Acceptance Test.

Evaluation of angular accuracy and resolution for Customer Acceptance Test.

Statement confirming the system meets required specifications.

Protocol details for customer acceptance test of Parallel Beam with Co anode.

Details of instrument configuration for D8 ADVANCE in Customer Acceptance Test.

Evaluation of angular accuracy and resolution for Customer Acceptance Test with Co anode.

Protocol for performing daily checks on the instrument's performance.

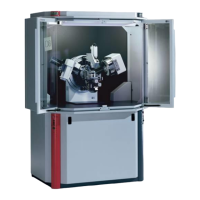

| Manufacturer | Bruker |

|---|---|

| Series | D8 |

| X-ray Source | Sealed tube or rotating anode |

| Goniometer | Various types available, including θ/θ, θ/2θ, and vertical goniometers |

| Sample Stage | Various options including XYZ stages and sample changers |

| Software | DIFFRAC.SUITE |