Introduction

6 / 96 DOC-M88-EXX157_V17_04.2019

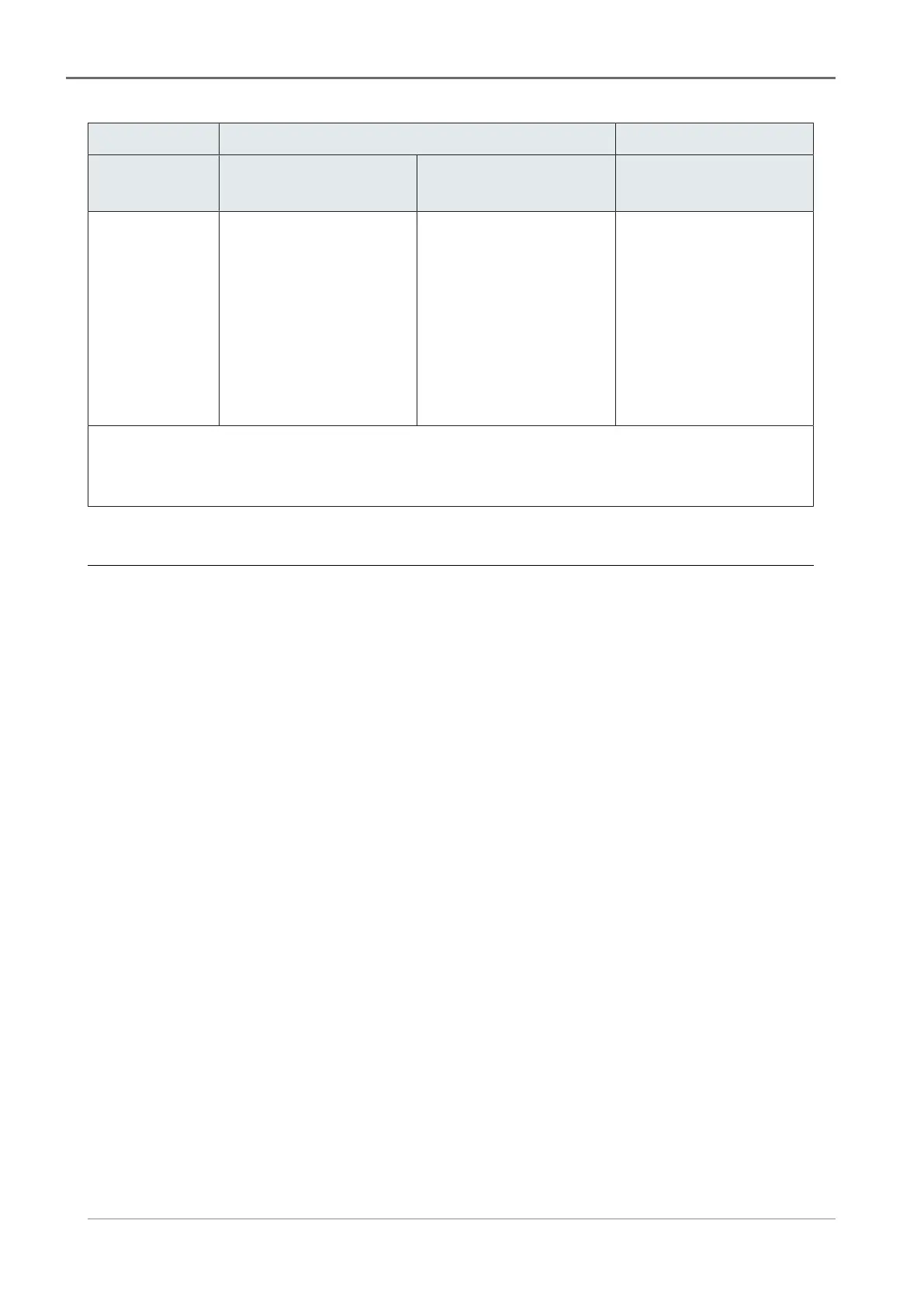

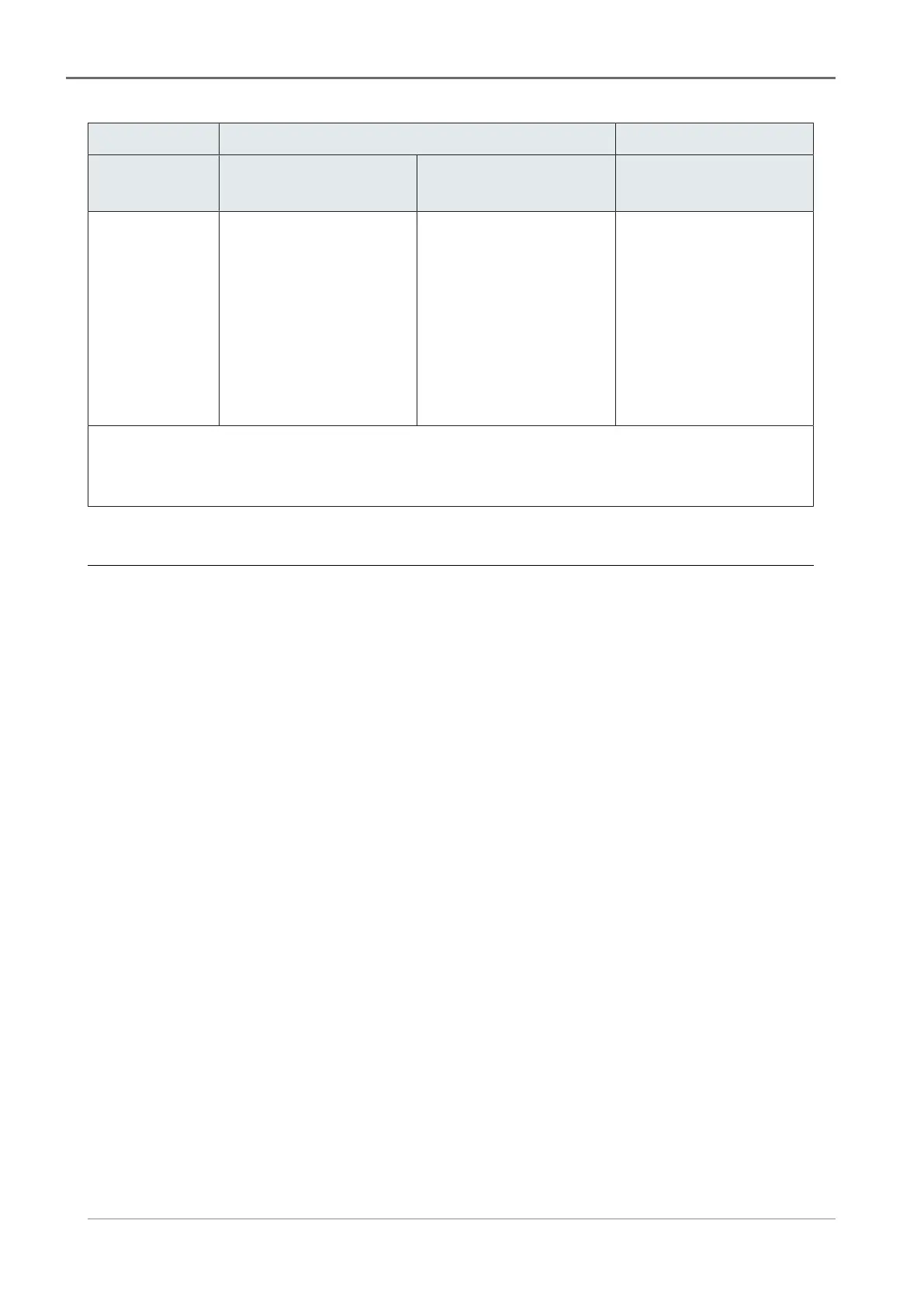

Bragg-Brentano Systems Parallel Beam Systems

Diffractometer D8 ADVANCE

1)

D8 DISCOVER

D8 ENDEAVOR

2)

D8 ADVANCE

1)

D8 DISCOVER

Detector Scintillation counter

Solid state detector

(SOL‑XE)

Linear detector VÅNTEC‑1

Linear detector LYNXEYE/

LYNXEYE‑2/

LYNXEYEXE/

LYNXEYEXE‑T/

SSD160/ SSD160‑2

EIGER2R500K

LYNXEYEXE

LYNXEYEXE‑T

LYNXEYE‑2

SSD160‑2

Scintillation counter

Solid state detector

(SOL‑XE)

Linear detector VÅNTEC‑1

Linear detector LYNXEYE/

LYNXEYE ‑2/

LYNXEYEXE/

LYNXEYEXE‑T/

SSD160/ SSD160‑2

EIGER2R500K

1)

Including D8 ADVANCE ECO

2)

Including D8 ENDEAVOR ECO

3)

Adjustment knife edge required

4)

Including motorized and manual air scatter screen

1.1 Performance Verification Levels

For instrument verification three performance verification levels are defined, which cover the

functionality of all relevant components of the diffraction system under investigation.

Measurement and evaluation procedures for each test level are detailed in section Proce-

dures [}9]. Protocol templates for full documentation are provided in the Appendices A to I

[}20].

Factory Acceptance Test

The factory acceptance test is performed at the manufacturer's site and designed to guaran-

tee the perfect performance of the system after its initial assembling.

Customer Acceptance Test

The customer acceptance test is identical to the factory acceptance test but performed at the

customer’s site and guarantees the perfect condition of the system after delivery and installa-

tion. The customer acceptance test procedure should be also performed after instrument re-

pairs or when the setup of the instrument has been modified.

Daily check

The daily check routine is a procedure to routinely check that the instrument is operating

within specified limits.

Loading...

Loading...