TE-BBR Instruction and Operation Manual

Appendix 3 – Technical Note 0611091

BBR Crack Seal Option Installation

This technical note describes the procedure for installing the Crack Seal Option (p/n 44.0675) for the

Thermoelectric Bending-Beam Rheometer. Refer to Table 9 for components of the Crack Seal kit.

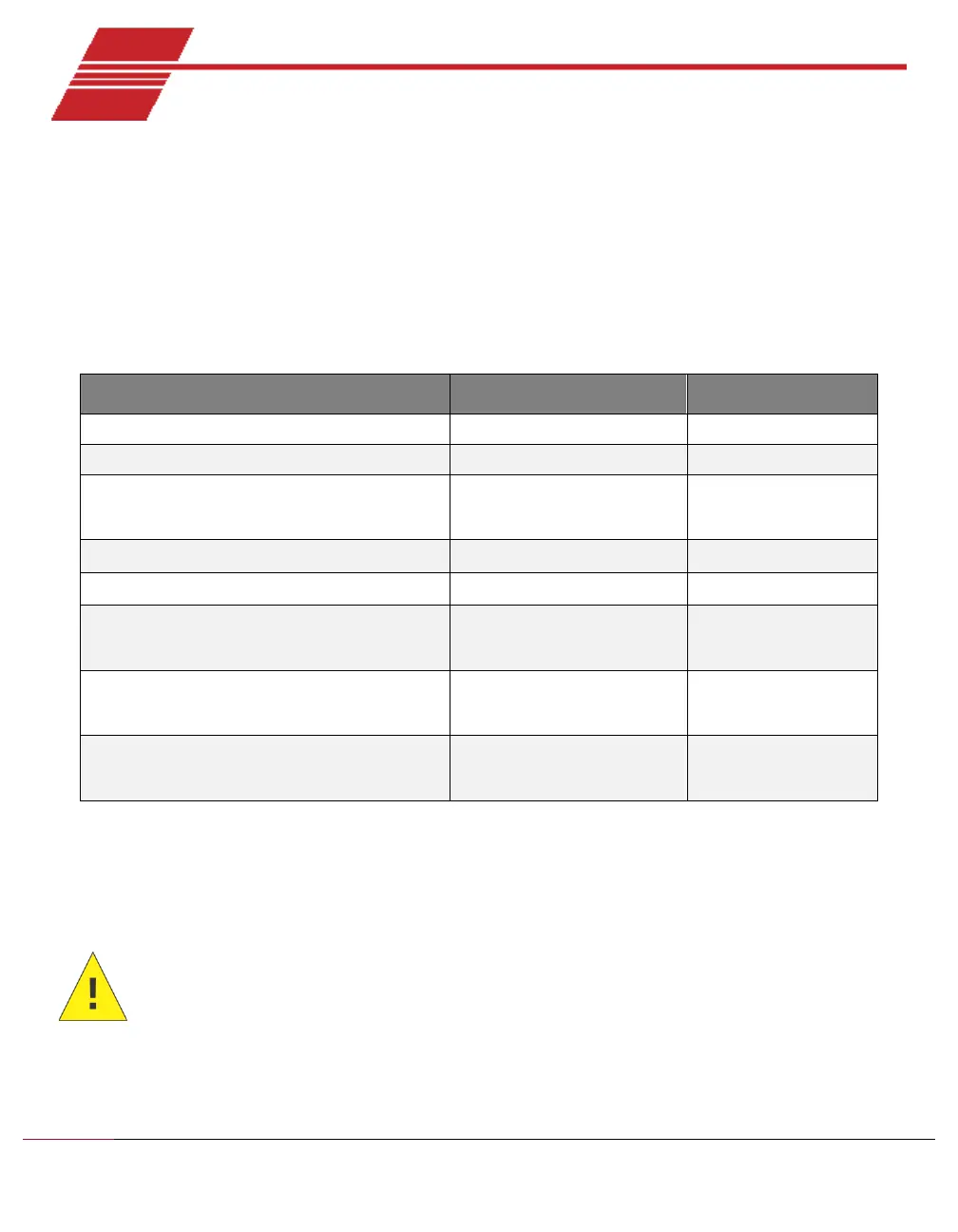

Table 9: BBR Crack Seal Kit Components (p/n 44.0675)

Binder with Calibration Certificates

6-32 ½-inch Phillips flat-head screws

6-32 3/8-inch Phillips flat-head

screws

01.0880

2

Adaptor, Support, Crack Seal

Thin beam assembly for Crack Seal

verification

44.0663

1

New ½” thick beam for Crack Seal

calibration

44.0664

1

Application Note 0611091-Crack Seal

Installation Instructions

44.0910

1

Tools Required: Stubby #2 Phillips screwdriver, stubby flat blade screwdriver, absorbent paper

towels

Replacement Procedure

Caution: Turn off TE-BBR and remove MAINS power from the instrument heat

exchanger power supply before beginning procedure. Instrument is heavy, use

two or more people for this procedure.

1. Disconnect the Load Frame from the Control Unit. Remove the four bayonet signal connectors and

the two air line connections at the rear of the Load Frame.

Loading...

Loading...