21

ENGLISH

ir33 +030220441 - rel. 2.0 - 01.05.2006

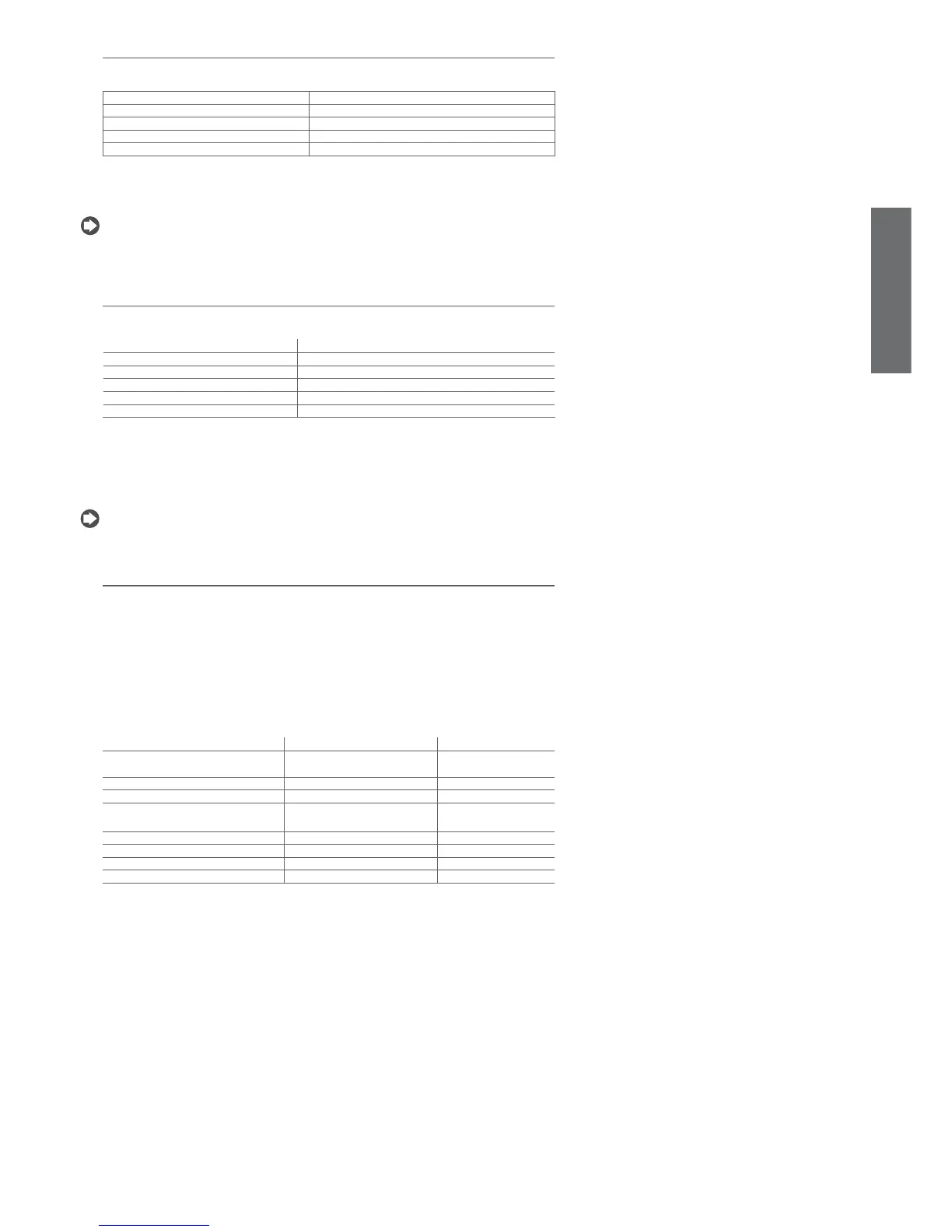

6.4 Auxiliary output management

The auxiliary output can be controlled by a number of sources: button, supervisor, digital input, and time

band. The AUX is switched on and off in the following events:

Aux Action

Button pressing the button

Supervisor variation in value from the supervisor

Digital input change in the status of the contact (opening/closing)

Time band according to day, hour, minutes for switching on/off

Tab. 6.e

Therefore, if the digital inputs are stable, the AUX output can always be activated and de-activated from the

keypad or the supervisor. The timed light or AUX on/off events (parameters tON and tOFF, depending on

parameter H8) are also active when the unit is off.

Note: the anti-sweat heater function, when the control is powered up or switched on, keeps the auxiliary

output off until the control temperature is below the set value. The AUX output is activated when the

event occurs.

6.5 Light management

The light can be controlled by a number of sources: button, supervisor, door switch and curtain switch.

The light is switched on and off in the following events:

Light Action

Button pressing the button

Supervisor variation in value from the supervisor

Door switch change in the status of the contact (opening/closing)

Curtain switch change in the status of the contact (opening/closing)

Light sensor on detecting light or darkness

Tab. 6.f

When the digital inputs (selected as door or curtain switches) are stable, the light can always be switched

on or off from the keypad or the supervisor. The door switch features two different algorithms for

switching the light on/off:

• the status of the light is not affected, and acts only on the compressor and fans;

• timed light or AUX on/off events (depending on parameter H8) are also active when the unit is off.

Note: the anti-sweat heater function, when the control is powered up or switched on, keeps the light

output off until the control temperature is below the set value. The light output is activated when the

event occurs.

6.6 Defrost

The parameter dC establishes the measurement unit for the times set by the parameters dI (defrost

interval) and dP1, dP2 (maximum defrost duration). If the auxiliary relay is selected as the auxiliary

evaporator defrost output (H1), the defrost is performed at the same time on both evaporators.

The parameter d/1 displays the defrost probe set for the main evaporator (the fi rst probe assigned as

a defrost probe); while parameter d/2 displays the defrost probe set for the secondary evaporator (the

second probe assigned as a defrost probe). If no probes have been assigned to the defrost function, the

defrost will end by timeout, after the periods dt1 and dt2.

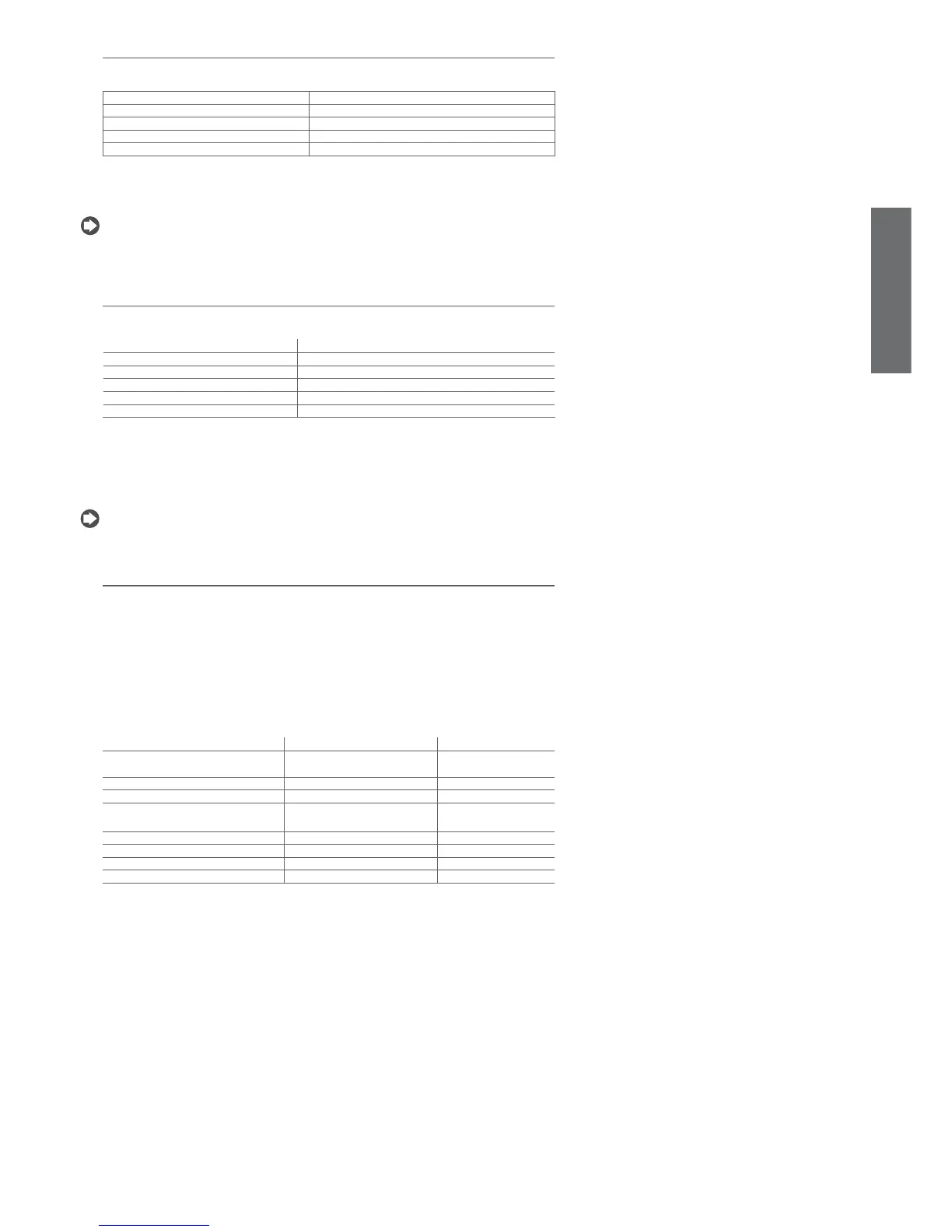

6.6.1 Defrost events

The following events activate the defrost function:

Event Implementation Condition

Interval between defrosts dI expired Depending on enabling status At the expiry of the interval

Expiry of RTC trigger Depending on enabling status -------

Compressor running time Depending on enabling status When the defrost starts

Interval between defrosts dI expired with

skip defrost algorithm

Depending on enabling status At the expiry of the interval

At start-up Depending on enabling status At start-up + d5

Digital input Depending on enabling status When the defrost starts

Supervisor Always --------

Keypad Always --------

Tab. 6.g

Implementation of defrost depending on enabling status:

If a digital input is confi gured to enable the defrost, the defrost is performed when such input is in the

enabling status, otherwise it stays pending.

Important: the defrost started from the keypad or by the supervisor is always performed, even when

there is a delayed defrost request from external digital input or if there is a defrost enabling input (in

non-enabled or delayed status). If parameter r3 is set to 1 (Direct) or 2 (Reverse), the defrost is never

performed.

6.6.2 Defrost request status

This status exists when one of the events that activates the defrost is present, but defrost cannot be

started and, therefore, is put on hold for the following reasons:

• compressor and fans start-up delay (c0), as these delay the activation of the compressor;

• compressor protection times (c1, c2, c3), as these delay the activation of the compressor;

• low pressure alarm (only with hot gas defrost), as this delays the activation of the compressor;

• continuous cycle running;

• pump down procedure running, as this delays the activation of the compressor;

• defrost delay at start-up (d5);

• defrost delay from digital input confi gured as defrost start or enable (d5);

• enable defrost (A4, A5);

Loading...

Loading...