28

Diagnostics

Troubleshooting—Sensors and Harnesses

To properly test the wiring and sensors on the header, follow the steps below in order. Use a Volt Meter

as needed.

The sensor connector pattern is as follows:

• Pin A is Ground (Black or Lt Blue)

• Pin B is Signal (White)

• Pin C is 5V (Green or Pink)

A very common problem during install is to reverse the wires at the connector after removing

the plug to route the cables. Make sure that the wires/voltages are as shown. If A & C are

reversed, the voltages will swing backwards.

The following requirements must be met before testing:

• Key on, combine engine running

• Header connected

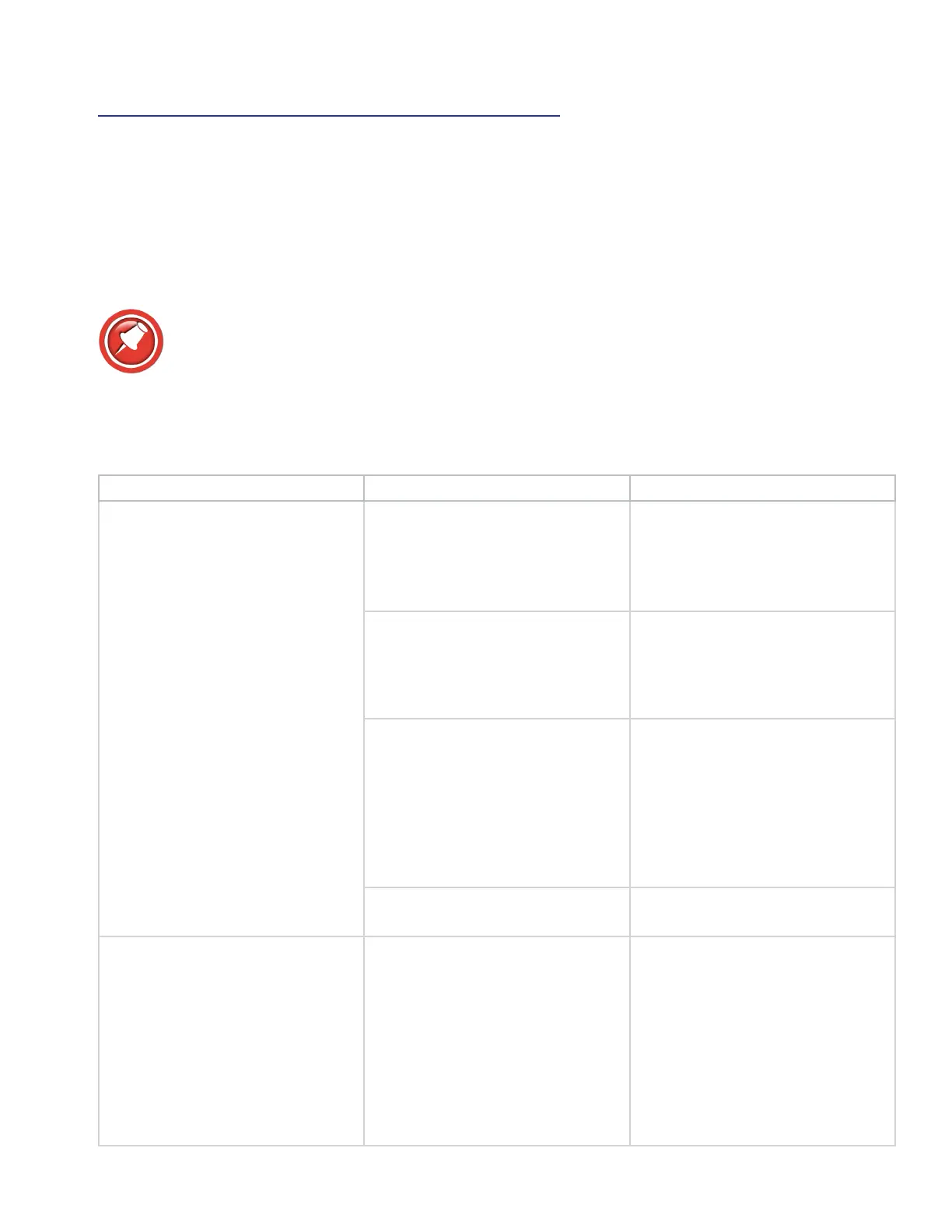

Error Code Problem Solution

Bad Harness Wiring

Disconnect Sensor Plug

(Measure voltage on harness

plug at sensor)

Measure C to Frame Ground

Voltage should be 5V

If not, check harness for

continuity or short on 5V wire

Check Combine 5V source

Measure C to A

Voltage should be 5V

If not check harness for

continuity on ground wire

Check combine sensor ground

source

Jump C to B in harness plug

Voltage should be 5V

(For Insight systems, see

“Diagnostics/Display Sensor

Voltages”. For all others, use

Combine Diagnostics*)

If not check signal wire

for broken harness or bad

connection

All of the above are correct Harness & combine connections

pass test.

If you have a Headsight Sensor

tester, use it to test the sensor.

For all other:

Verify sensor is connected to

extension harness

Sensor voltage should be 0.5-

4.5V

(For Insight systems, see

“Diagnostics/Display Sensor

Voltages”. For all others, use

Combine Specic Diagnostics)

If sensor cannot be adjusted

to achieve a voltage within the

range, replace sensor.

Loading...

Loading...